Chapter 2 Periodic Inspection

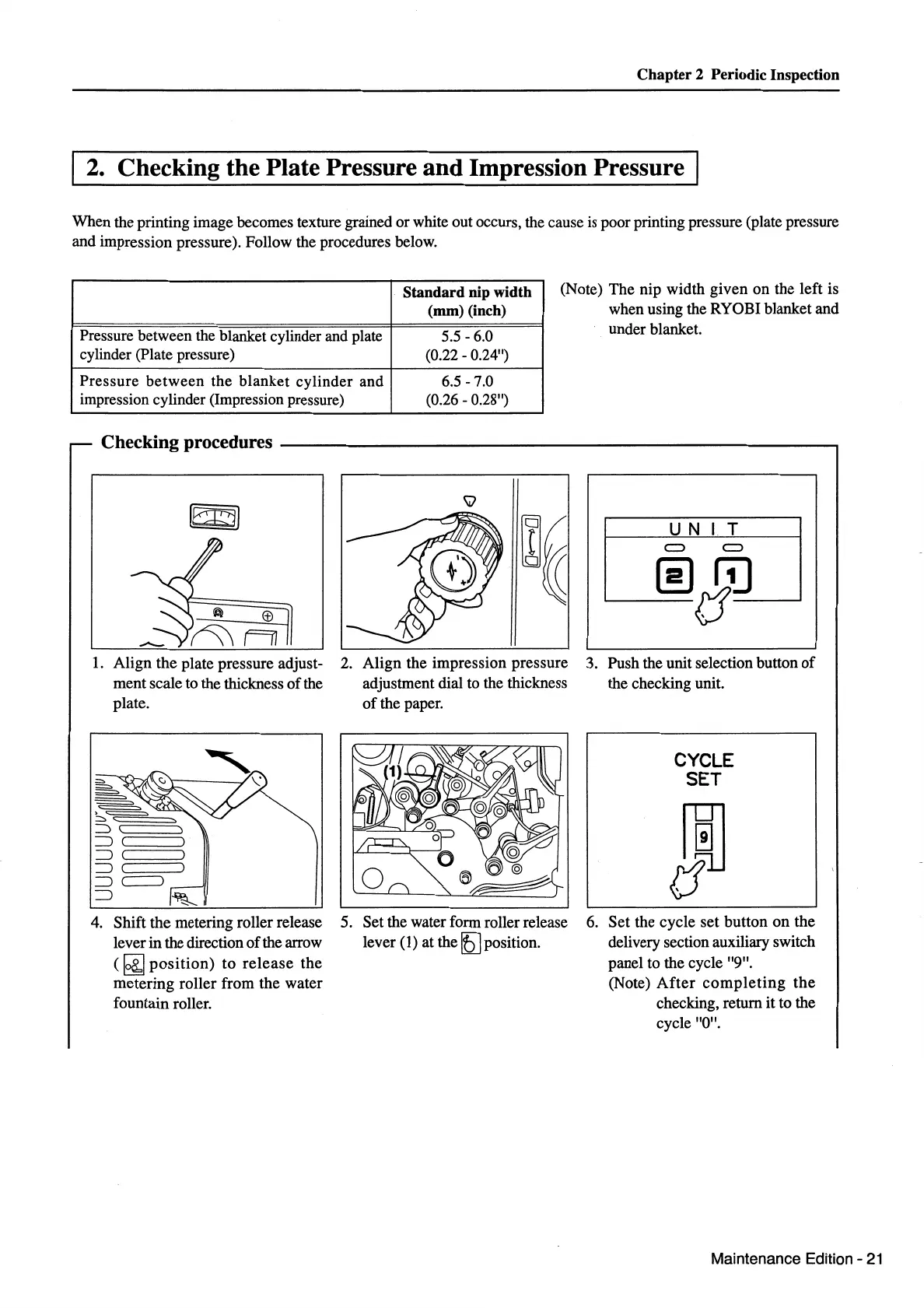

2. Checking the Plate Pressure and Impression Pressure

When the printing image becomes texture grained

or

white out occurs, the cause

is

poor printing pressure (plate pressure

and impression pressure). Follow the procedures below.

Standard nip width

(nun) (inch)

Pressure between the blanket cylinder and plate

5.5-6.0

(Note) The nip width given

on

the left is

when using the RYOBI blanket and

under blanket.

cylinder (Plate pressure)

(0.22 - 0.24")

Pressure

between

the

blanket

cylinder

and

6.5-7.0

impression cylinder (Impression pressure) (0.26 - 0.28")

Checking procedures

----------------------------,

1.

Align

the

plate pressure adjust-

ment scale to the thickness

of

the

plate.

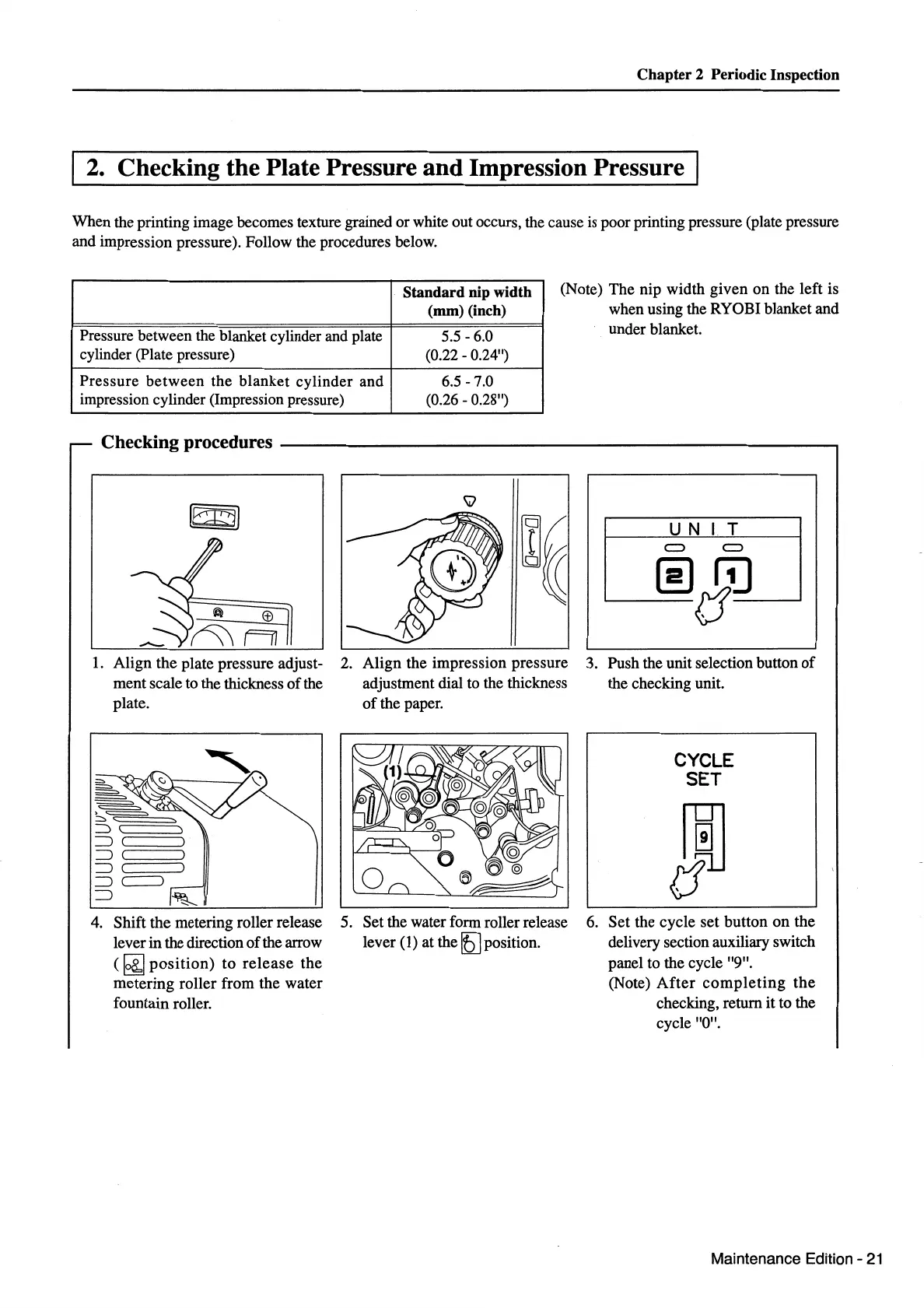

4. Shift

the

metering roller release

lever

in

the direction

of

the arrow

(

~

position)

to

release

the

metering

roller from the water

fountain roller.

2.

Align

the impression pressure

adjustment dial to the thickness

of

the paper.

5. Set the water form roller release

lever (

1)

at the It] position.

UNIT

3. Push the unit selection button

of

the checking unit.

CYCLE

SET

6.

Set

the cycle set button

on

the

delivery section auxiliary switch

panel to the cycle "9".

(Note)

After

completing

the

checking, return it to the

cycle "0".

Maintenance Edition-

21

Loading...

Loading...