Chapter 5 Troubles and Countermeasures

5-2 Other Troubles

When the troubles listed below occur during the printing, first follow the countermeasures given below and

if

the

trouble is not corrected then call your service technician for after sales service.

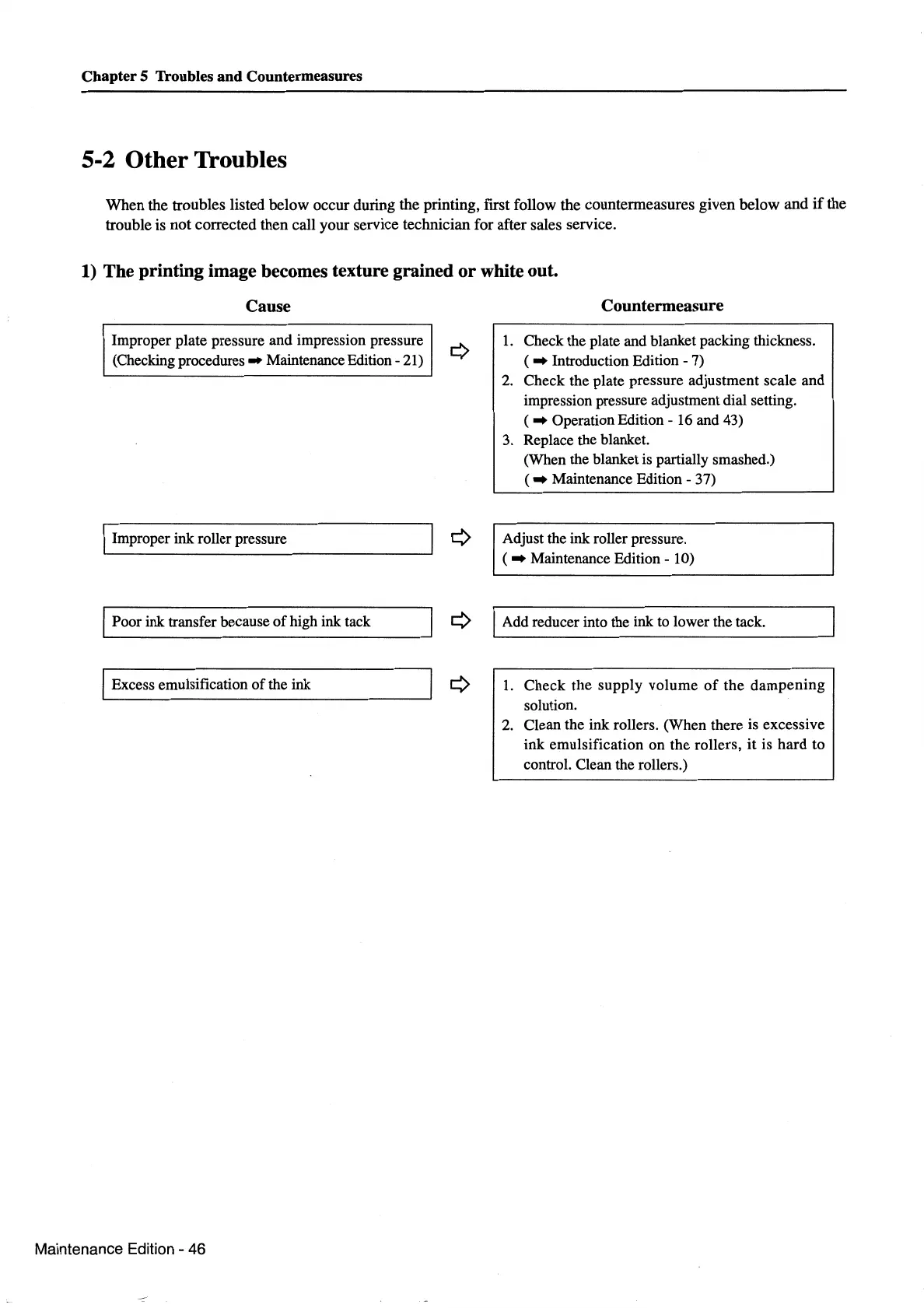

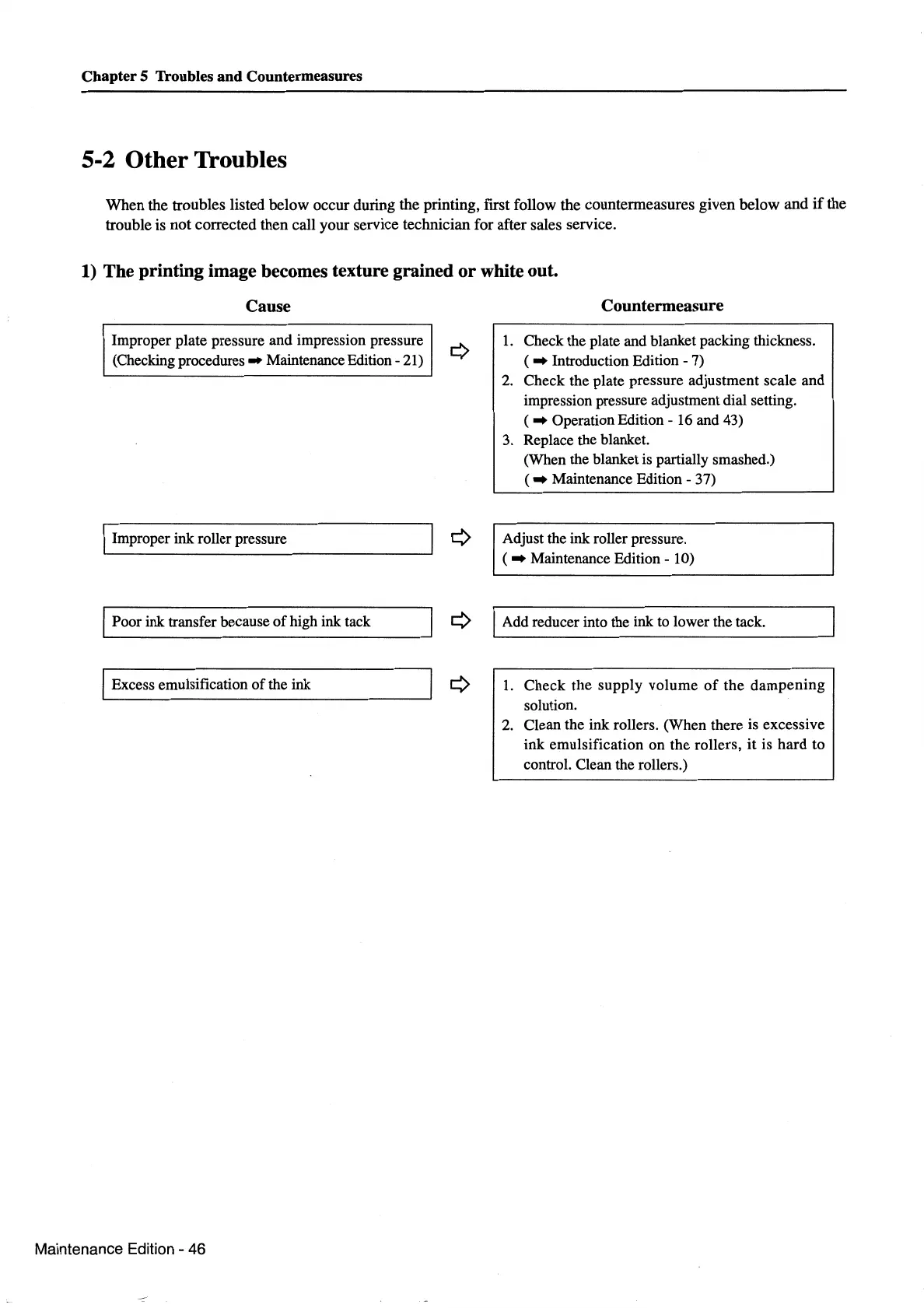

1) The printing image becomes texture grained or white out.

Cause

Improper plate pressure and impression pressure

(Checking procedures • Maintenance Edition- 21)

I Improper ink roller pressure

I Poor ink transfer because

of

high ink tack

I Excess emulsification

of

the ink

Maintenance Edition - 46

Countermeasure

1.

Check the plate and blanket packing thickness.

( • Introduction Edition - 7)

2.

Check the plate pressure adjustment scale and

impression pressure adjustment dial setting.

( • Operation Edition-

16

and 43)

3.

Replace the blanket.

(When the blanket

is

partially smashed.)

( • Maintenance Edition - 37)

Adjust the ink roller pressure.

( • Maintenance Edition- 10)

I Add reducer into the ink

to

lower the tack.

1.

Check the supply volume

of

the dampening

solution.

2.

Clean the ink rollers. (When there is excessive

ink emulsification on the rollers,

it

is hard to

control. Clean the rollers.)

Loading...

Loading...