Chapter

4 Replacing the Supplies

3. Replacing the Water Form Roller and Metering Roller

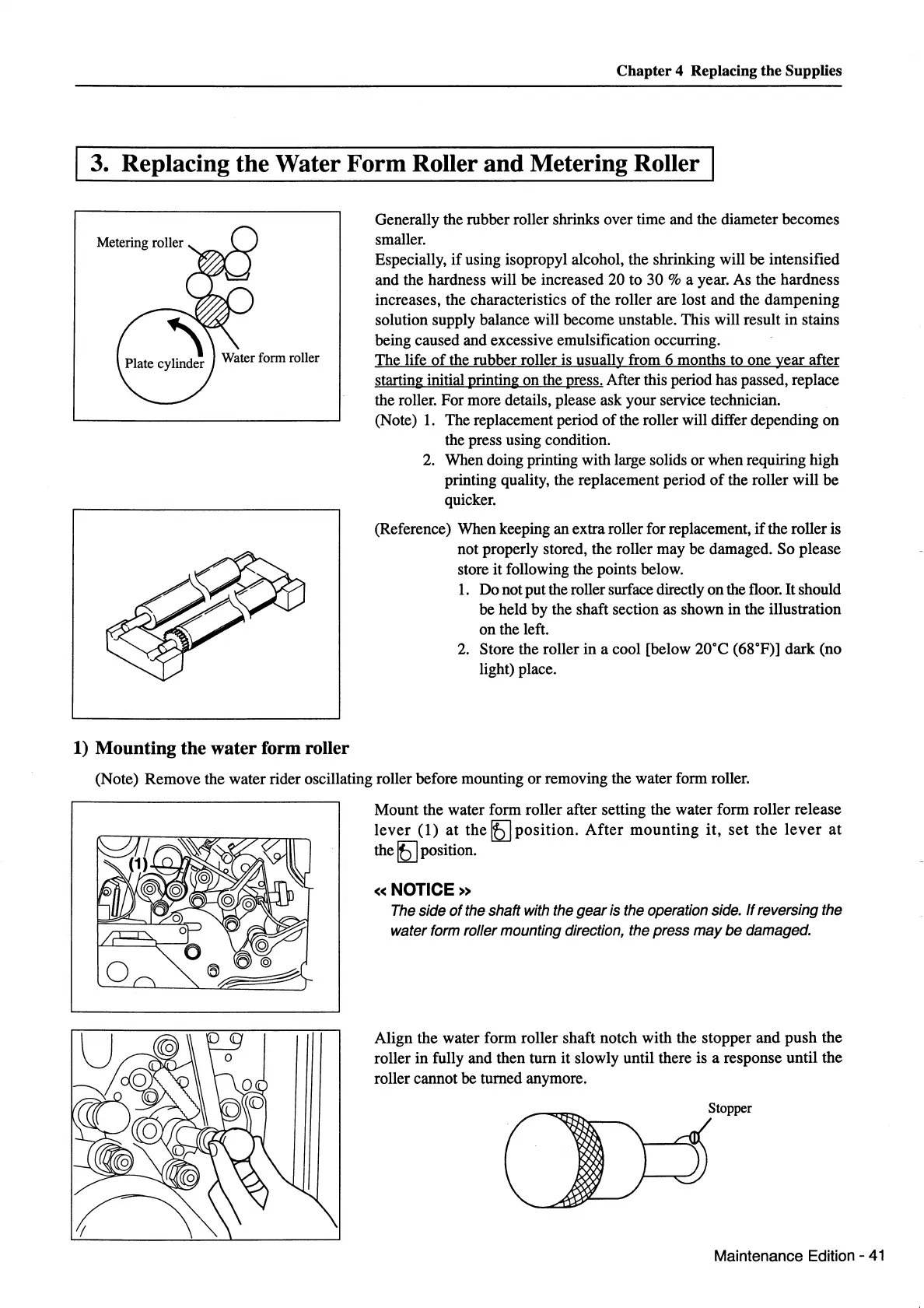

Metering roller

1) Mounting the water form roller

Generally the rubber roller shrinks over time and the diameter

becomes

smaller.

Especially,

if

using isopropyl alcohol,

the

shrinking will

be

intensified

and

the

hardness will

be

increased

20

to

30

% a year. As the

hardness

increases,

the

characteristics

of

the

roller

are

lost

and

the

dampening

solution supply balance will

become

unstable. This will result

in

stains

being caused and excessive emulsification occurring.

The

life

of

the

rubber

roller

is usually

from

6 months

to

one

year

after

starting initial printing

on

the press. After this period has passed, replace

the roller.

For

more

details, please ask

your

service technician.

(Note) 1. The replacement period

of

the roller will differ depending

on

the press using condition.

2.

When

doing printing with large solids

or

when

requiring

high

printing quality, the

replacement

period

of

the

roller

will

be

quicker.

(Reference)

When

keeping

an

extra roller for replacement,

if

the roller is

not

properly stored,

the

roller

may

be

damaged.

So

please

store

it

following

the

points below.

1.

Do

not

put the roller surface directly

on

the floor. It should

be

held

by

the

shaft

section as

shown

in

the illustration

on

the left.

2.

Store

the roller

in

a

cool

[below

2o·c

(68.F)]

dark

(no

light) place.

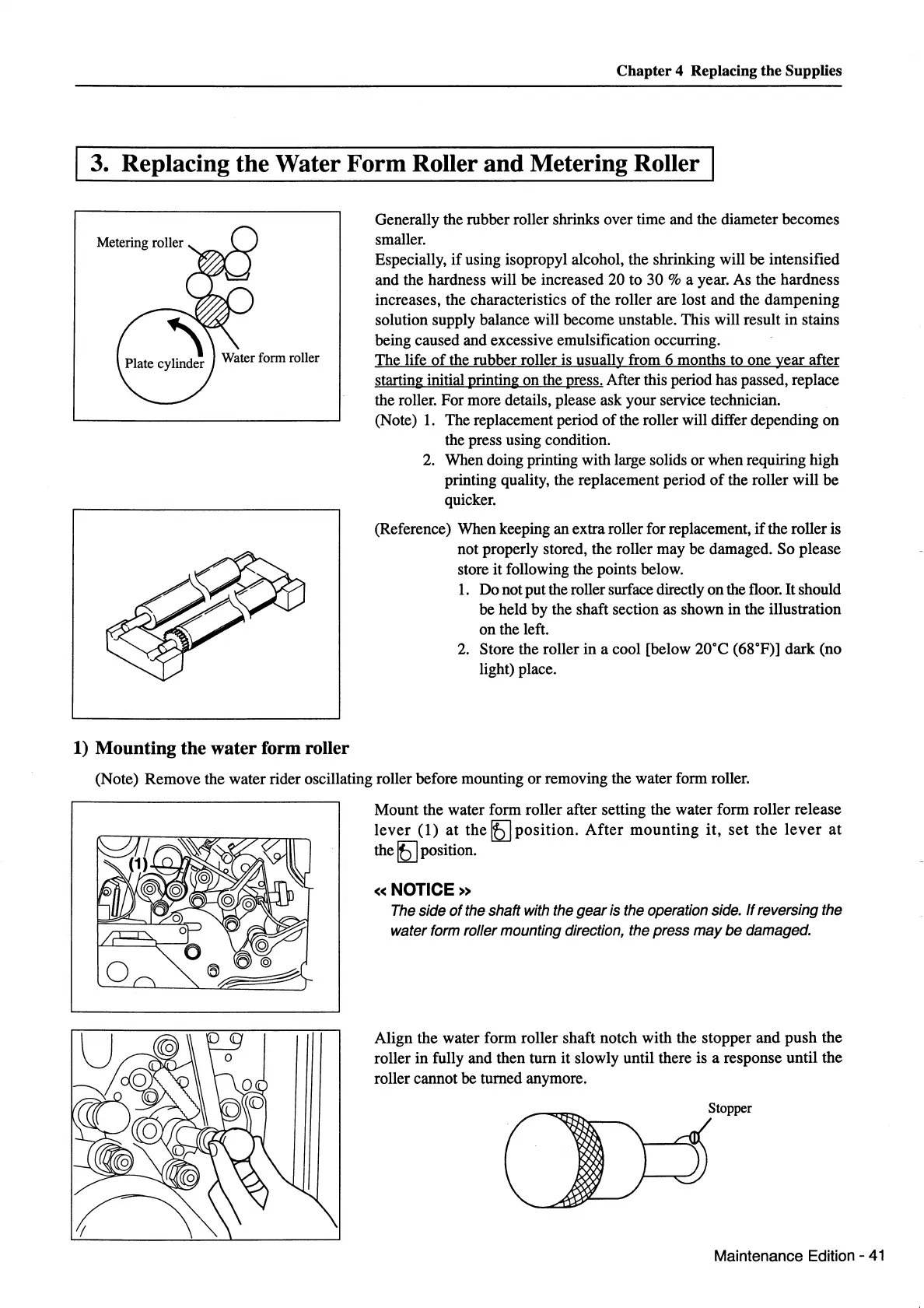

(Note)

Remove

the

water

rider oscillating roller before mounting

or

removing the

water

form roller.

Mount

the

water

form

roller

after

setting

the

water

form

roller

release

lever

(1)

at

the

It]

position.

After

mounting

it,

set

the

lever

at

the

IE]

position.

«NOTICE»

The

side

of

the

shaft

with

the

gear

is

the

operation

side.

If

reversing

the

water form roller mounting direction, the press may be damaged.

Align

the

water

form

roller

shaft

notch

with

the

stopper

and

push

the

roller

in

fully

and

then

tum

it

slowly

until there is a

response

until

the

roller

cannot

be

turned anymore.

Maintenance Edition -

41

Loading...

Loading...