*31545 – Sens. Correction Pitch

Each inclination sensor is pre-checked for accuracy and reproducibility in the

sensor chip in the housing can be never installed exactly in the 0-position, the

correction value in the longitudinal direction is recorded and entered on the

*31546 – Sens. Correction Roll

Proceed as for the sensor correction value in the longitudinal direction: See

above!

*31547 – Inst. Correction Pitch

The semitrailer is placed as accurately as possible in the 0° position in a longitu-

dinal direction prior to the calibration. (The 0° of the tank is described in the tank

-

direction, which must be corrected. The value displayed in the Diagnosis menu

must be entered here as a negative installation correction for the pitch.

*31548 - Inst. Correction Roll

Proceed as for the installation correction value in the longitudinal direction: See

above!

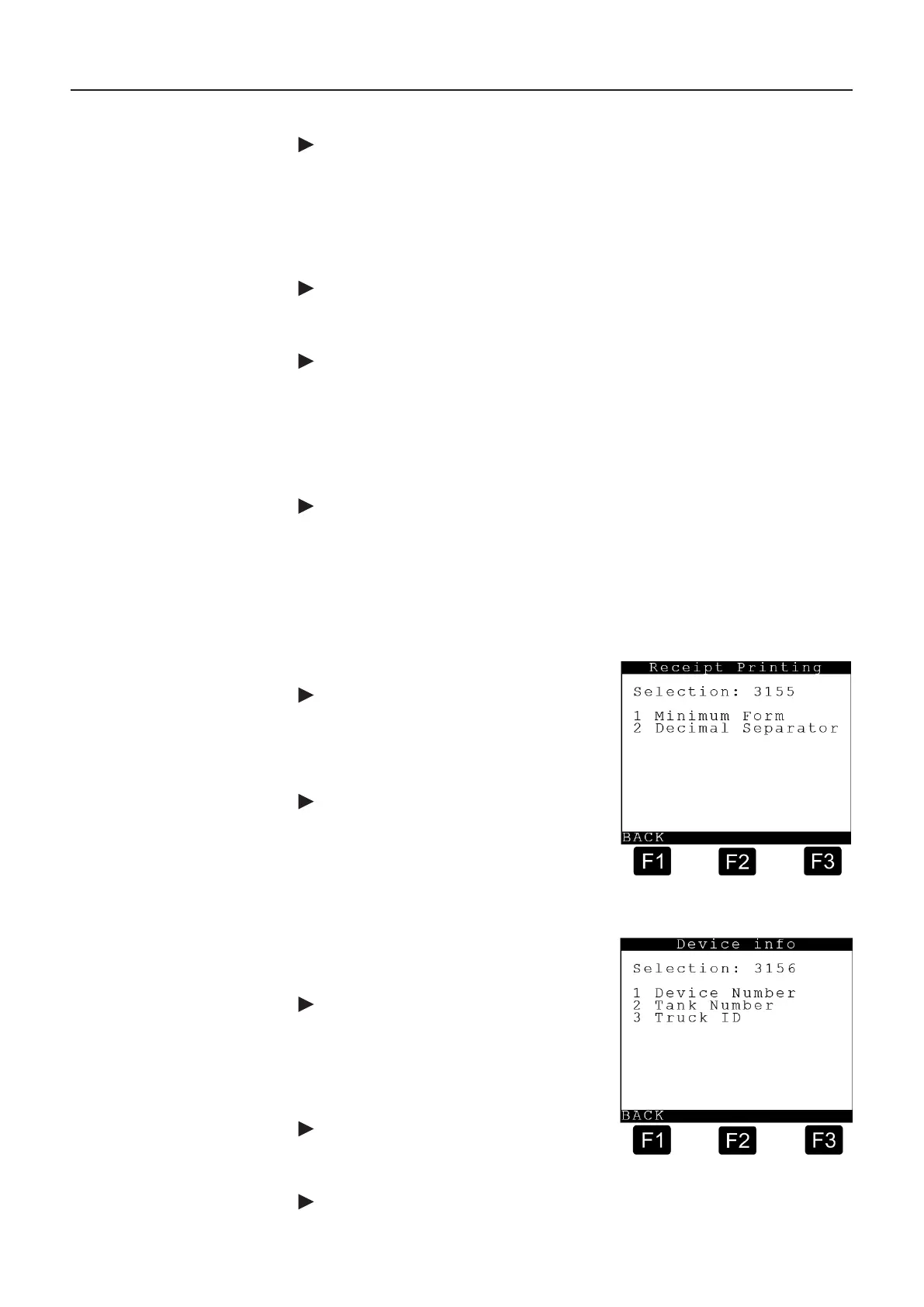

9.7.1.5.2. Printing – 3155

Additional calibration-relevant parameters concerning the receipt printout are listed here:

*31551 – Minimum Form

Minimum requirement of the weights

and measures authority for a printed

receipt; list of the minimum required

form elements.

*31552 – Decimal Separator

Selection of the decimal separator.

Possible values:

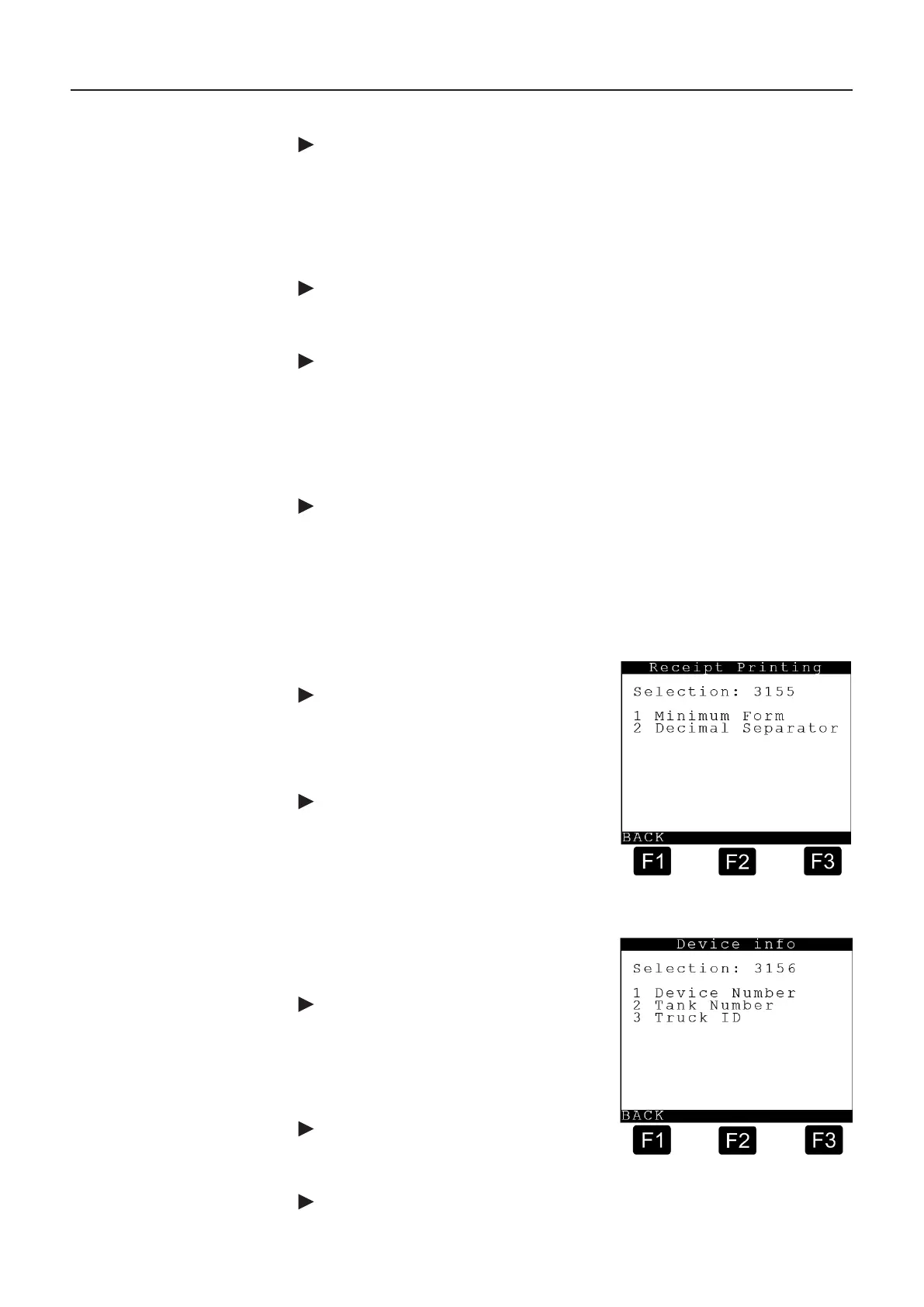

9.7.1.5.3. Device Info – 3156

Further device-specific settings are made here:

*31561 - Device number

Entry, for example, of the serial number

of the MultiLevel central unit. This is

additionally stored internally, where it

cannot be changed, and appears on

parameter and seal printouts as ‘Ser. no.’

*31562 – Tank number

The measuring tank serial number |

*31563 - Truck ID

MultiLevel Instruction Manual MENU structure

Loading...

Loading...