Whenever

you

change the

front

seal, it's a

good

idea

to

replace the

front

gasket (part

#1124)

as

well.

Once

you

have the

front

bear-

ing cap off,

you

can

pry

the

front

oil seal

out

of

it-see

Photo

8/27.

Remove the bearing cap

by

removing the three bolts,

shown

as A in

the

photo.

The

rubber

seal is marked B in

the

photo.

Then,

simply

put

on a new gasket (part

#1124), replace the cap, and

you

are ready

to

reinstall the seal over the shaft. When you do,

take great care and make sure the

keyway

for

the transmission

pulley

and the grooves on the

shaft

for

the snap rings

don't

have any sharp

edges

that

will

cut

the seal.

Either

roll up a

piece

of

letter paper

stationery

to

cover

the key-

way,

or

wrap

the keyway in transparent tape

before

pushing

the seal over the

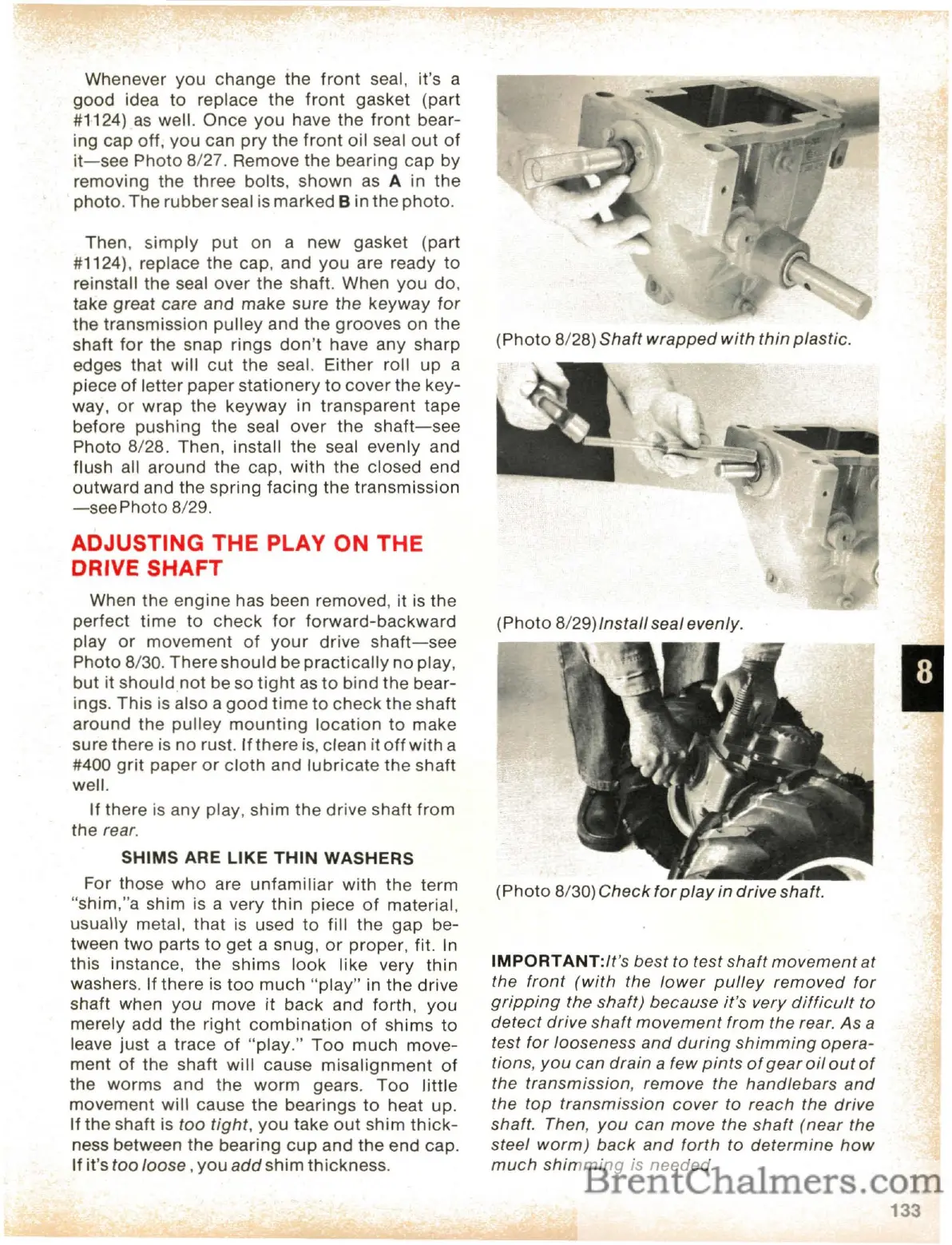

shaft-see

Photo

8/28.

Then, install the seal evenly and

flush all

around

the cap,

with

the closed end

outward

and the

spring

facing the transmission

-see

Photo 8/29.

ADJUSTING THE PLAY ON THE

DRIVE SHAFT

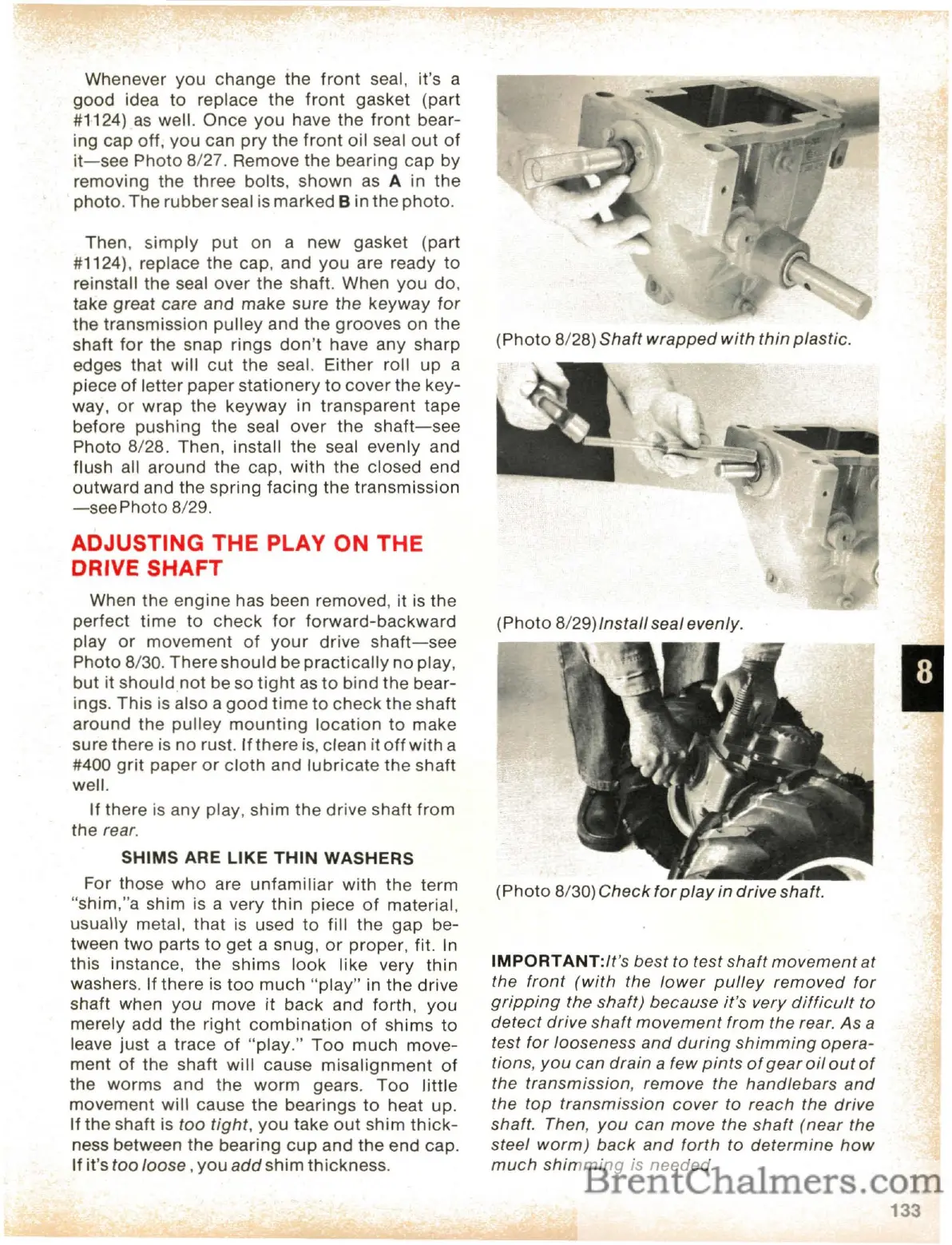

When the

engine

has been removed, it is the

perfect time

to

check

for

forward-backward

play

or

movement

of

your

drive

shaft-see

Photo 8/30. There

should

be

practically

no

play,

but

it

shouldnot

be so

tight

as

to

bind

the bear-

ings. This is also a

good

time

to

check

the shaft

around the

pulley

mounting

location

to

make

su

re

there is

no

rust.

If

there is, clean it

off

with

a

#400

grit

paper

or

cloth

and

lubricate

the

shaft

well.

If there is any play, shim the drive shaft

from

the rear.

SHIMS ARE LIKE

THIN

WASHERS

For those

who

are

unfamiliar

with

the

term

"shim,"a shim is a very

thin

piece

of

material,

usually metal,

that

is used

to

fill the gap be-

tween two parts

to

get a snug,

or

proper, fit. In

this instance, the shims

look

like very

thin

washers. If there is

too

much

"play"

in the drive

shaft when you move

it

back

and forth,

you

merely add the

right

combination

of

shims

to

leave just a trace

of

"play."

Too

much

move-

ment

of

the shaft

will

cause

misalignment

of

the

worms

and the

worm

gears.

Too

little

movement

will

cause

the

bearings

to

heat up.

If the shaft is

too

tight,

you take

out

shim

thick-

ness between the bearing

cup

and the end cap.

If it's

too

loose,

you

add

shim thickness.

(Photo

8/28)

Shaft

wrapped

with

thin

plastic.

(Photo

8/29)

Install

seal

evenly.

(Photo 8/30)

Check

for

play

in

drive

shaft.

IMPORTANT:/t's

best

to

test

shaft

movement

at

the

front

(with

the

lower

pUlley

removed

for

gripping

the

shaft)

because

it's

very

difficult

to

detect

drive

shaft

movement

from

the rear.

As

a

test

for

looseness

and

during

shimming

opera-

tions,

you

can

drain

a few

pints

of

gear

oil

out

of

the

transmission,

remove

the

handlebars

and

the

top

transmission

cover

to

reach

the

drive

shaft. Then,

you

can

move

the

shaft

(near

the

steel

worm)

back

and

forth

to

determine

how

much

shimming

is needed.

I

133

Loading...

Loading...