50

REPLENISHING OIL

You

will

note

that

the

capacity

of

your

7 HP

engine is

about

1/2

pint

more than one

quart

of

tnotor

oil when

filling

a new engine

or

a

short

block

for

an

engine

repair.

It

is assumed that

some

dirty

oil

will

likely

cling

to

the

sidewalls

of

the

engine crankcase, especially ifthe engine

is

drained

while

it is cold.

It

should

take about one

quart

to

bring

the

new oil

up

to

proper

level.

Please Note: It is recommended that

you

run the

engine

for

10

or

15

minutestoheattheoil

up

be-

fore

draining

it.

This

will

minimize

the

amount

left in

the

engine.

Large masses

of

dirt

and

grime

often come

out

with

the last few ounces

of

oil, so drain

the

engine

completely

by

tilting

the enginetowards

the

drain hole

(put

a

thick

board

or

brick

under

one Wheel).

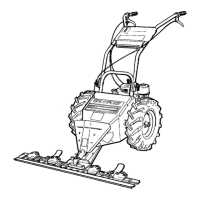

THROTTLE CABLE

The

throttle

cable

on

a 7 HP Troy-8i1t

Tiller

runs

down

the

right

handlebar and dips

down

outside

of

the

yoke

(which

raises the engine to

tighten

the belts) and across

to

the

governor

tontrol

disc. A small metal clamp and a screw

holds

the

throttle

casing in position. See Photo

4/27

for

the

routing

of

the cable and the next

photo

for

close

up

details.

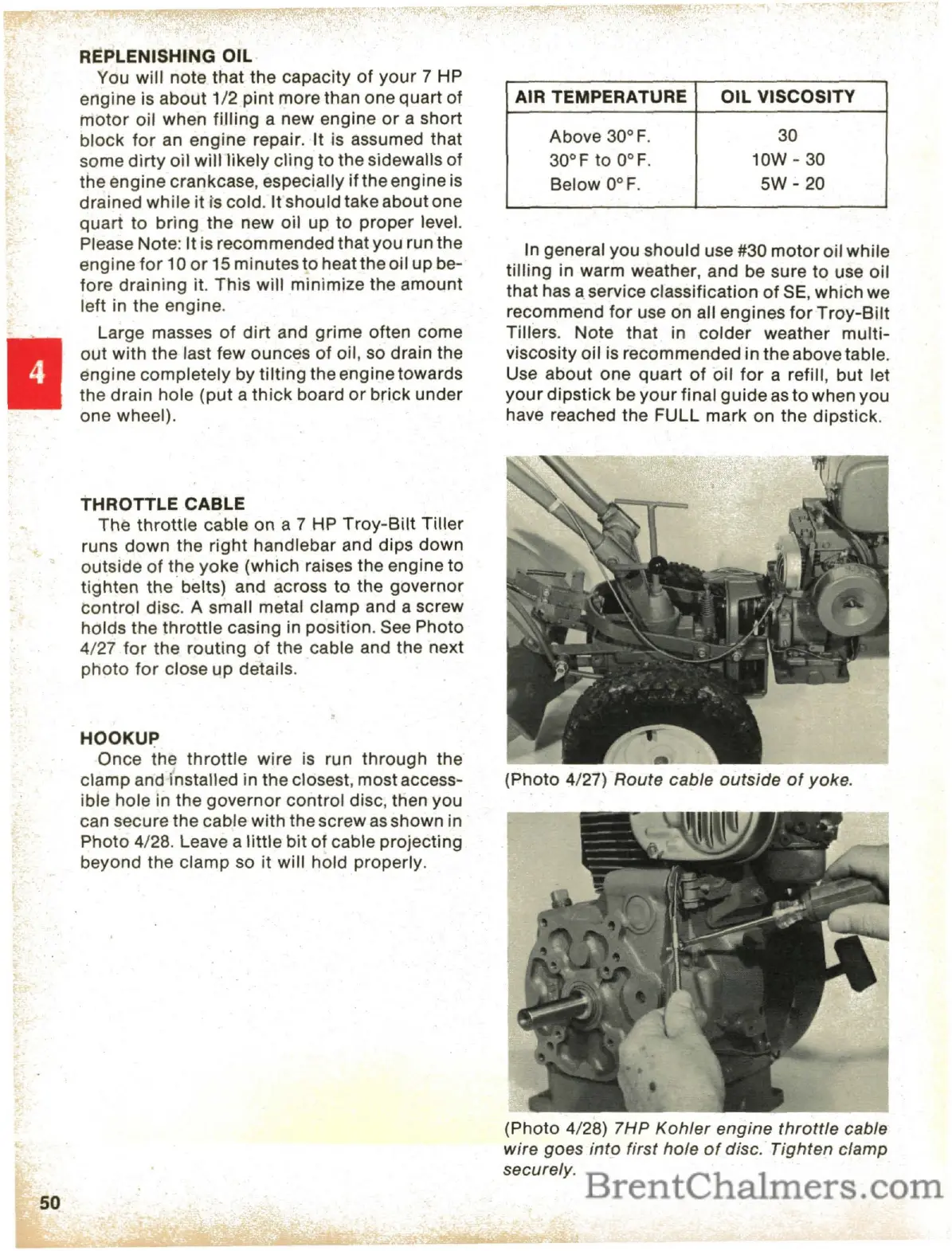

HOOKUP

Once the

throttle

wire

is run

through

the

clamp and

i'nstalled in the closest, most access-

ible hole in the

governor

control

disc, then

you

can secure the cable

with

the screw

as

shown in

Photo

4/28. Leave a

little

bit

of

cable

projecting

beyond the

clamp

so it will hold properly.

AIR TEMPERATURE OIL VISCOSITY

Above 30°F.

30

30°F to

OaF.

10W - 30

8elow

OaF.

5W - 20

In general you

should

use #30

motor

oil

while

tilling

in warm weather, and be sure to use

oil

that

has

a.

service classification

of

SE,

which

we

recommend

for

use on all engines

for

Troy-8i1t

Tillers.

Note

that

in

colder

weather

multi-

viscosity

oil

is recommended in

the

above table.

Use

about

one

quart

of

oil

for

a refill,

but

let

your

dipstick

be

your

final

guide

as

to

when

you

have reached

the

FULL mark on

the

dipstick.

(Photo 4/27) Route cable

outside

of

yoke.

(Photo 4/28) THP

Kohler

engine

throttle

cable

wire goes

into

first hole

of

disc. Tighten clamp

securely.

Loading...

Loading...