Step

4.

Disconnect

the

battery recharging line

(8

in

Photo

8/131), also

shown

in Photo 8/132.

Step

5.

Disconnect

the cable leading from the

left side

of

the solenoid

(as

you

stand in

front

of

it) to the starter

motor.

This is the cable leading

from

the

starter

motor

at

the

engine

back

to

the

solenoid. Replace the

nut

on the starter

motor

post

so

that

it

doesn't

get

lost (see

Photo

8/133).

I

Step

6.

Remove the

two

bolts fastening the bat-

tery bracket

to

the

tiller

transmission.

The

en-

tire battery assembly

will

lift

off

while it

is

in-

tact. Replace the

bolts

in the transmission cover.

See Photos

8/134

and 8/135.

PREPARING A TILLER

TRANSMISSION FOR SHIPMENT

By

using

fir, pine

or

scrap lumber,

you

can

construct

a

shipping

case

for

shipment

of

your

tiller

transmission in the method illustrated

by

the photos.

The

2 x 4

blocks

supporting

the

wheel axle are

cut

out, notched,

or

plowed

out

to

create a cradle

forthe

wheel shaft (Photo 8/136).

Instead

of

the metal strapping, some owners

have used

strong

wire

to

hold the transmission

fast to the skid.

The

plywood

cover

is

nailed

with

box

nails

into

the

skid.

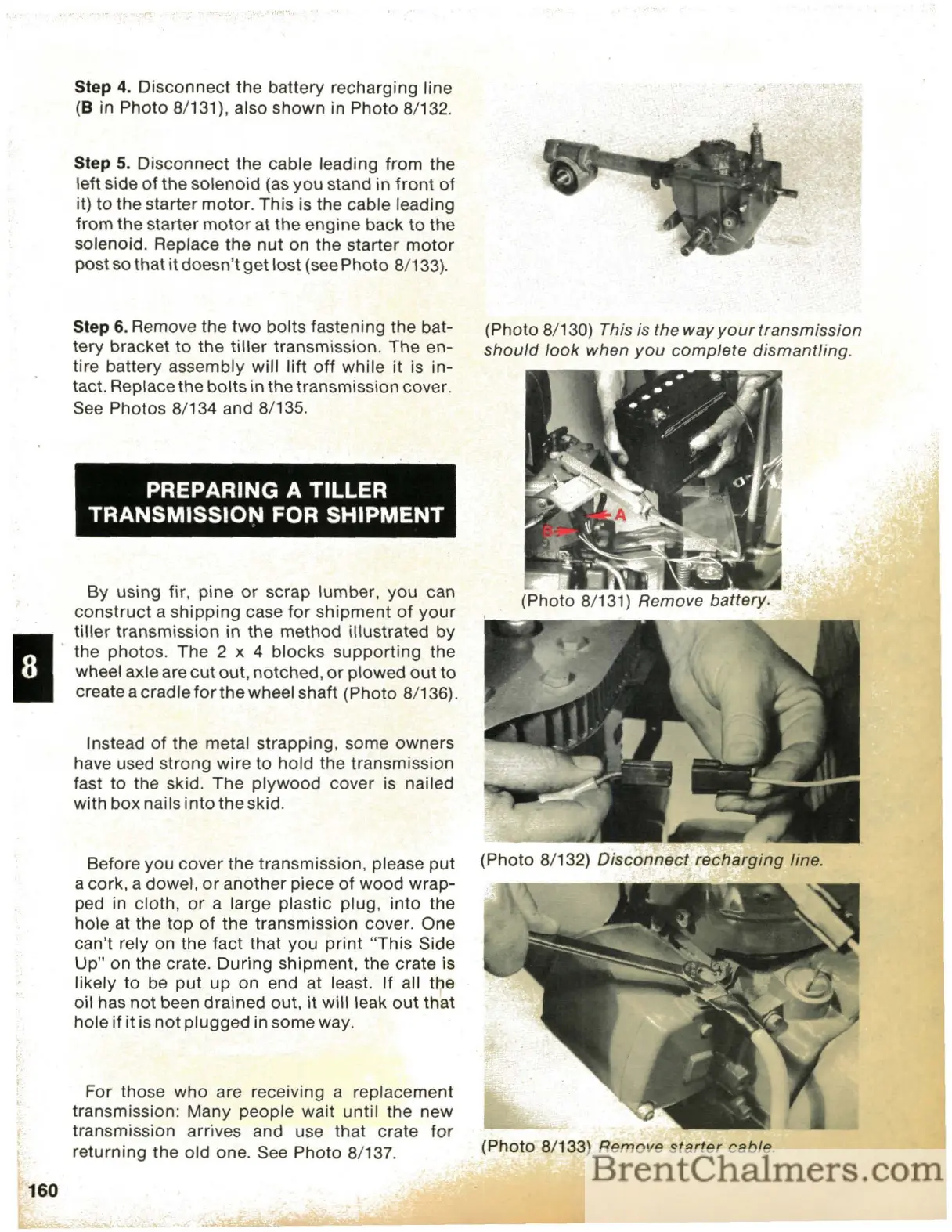

(Photo

8/130)

This is the way

your

transmission

should

look

when

you

complete

dismantling.

160

Before you

cover

the transmission, please

put

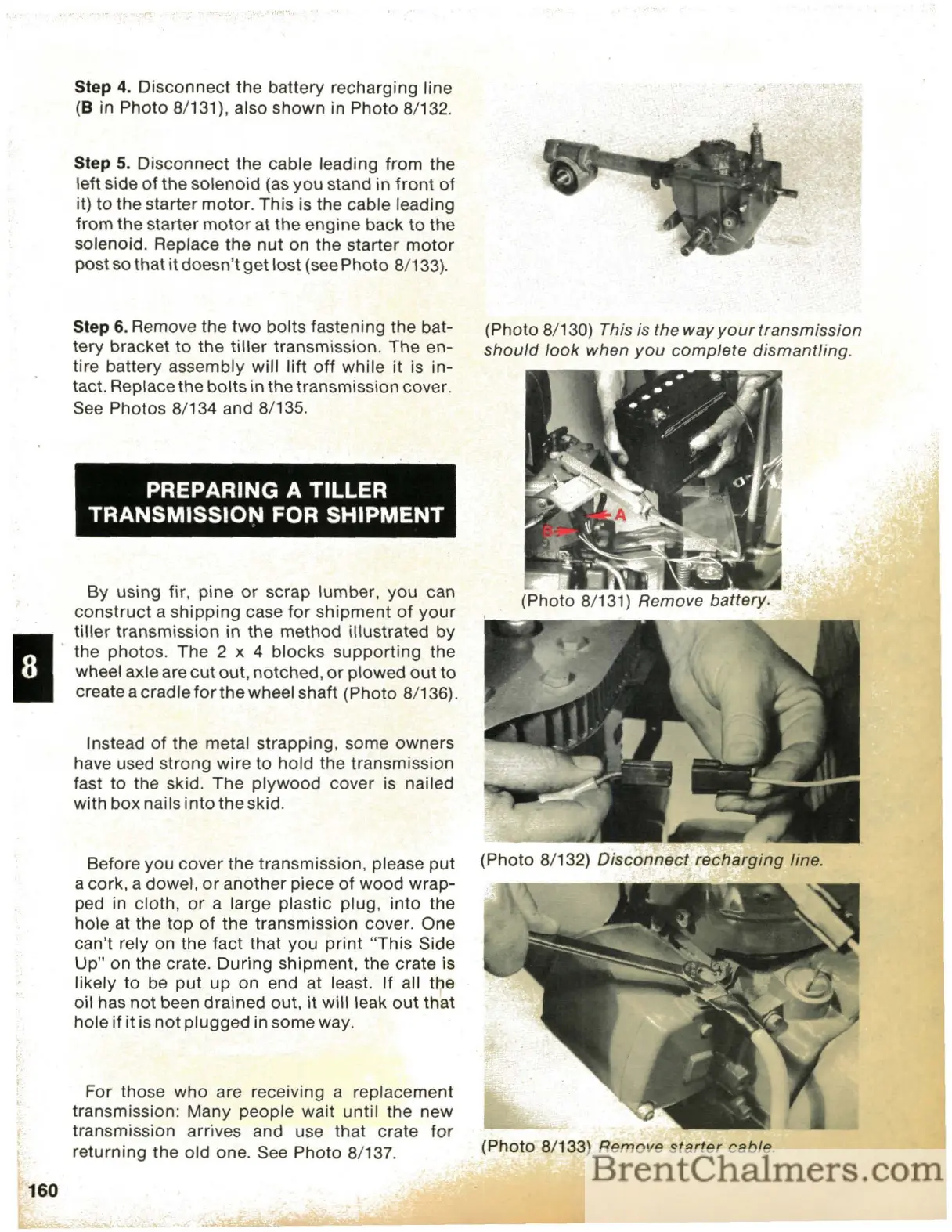

(Photo

8/132)

Disconnect

recharging

line.

a cork, a dowel,

or

another

piece

of

wood

wrap-

ped in cloth,

or

a large plastic plug,

into

the

hole at the

top

of

the

transmission cover. One

can't rely on the fact

that

you

print

"This

Side

Up"

on the crate.

During

shipment, the crate is

likely

to

be

put

up

on end at least. If all the

oil has

not

been drained out, it

will

leak

out

that

hole if it is

not

plugged

in some way.

For those

who

are receiving a replacement

transmission:

Many

people wait

until

the new

transmission arrives and use that crate

for

returning

the

old one. See Photo

8/137.

(Photo 8/133) Remove

starter

cable.

Loading...

Loading...