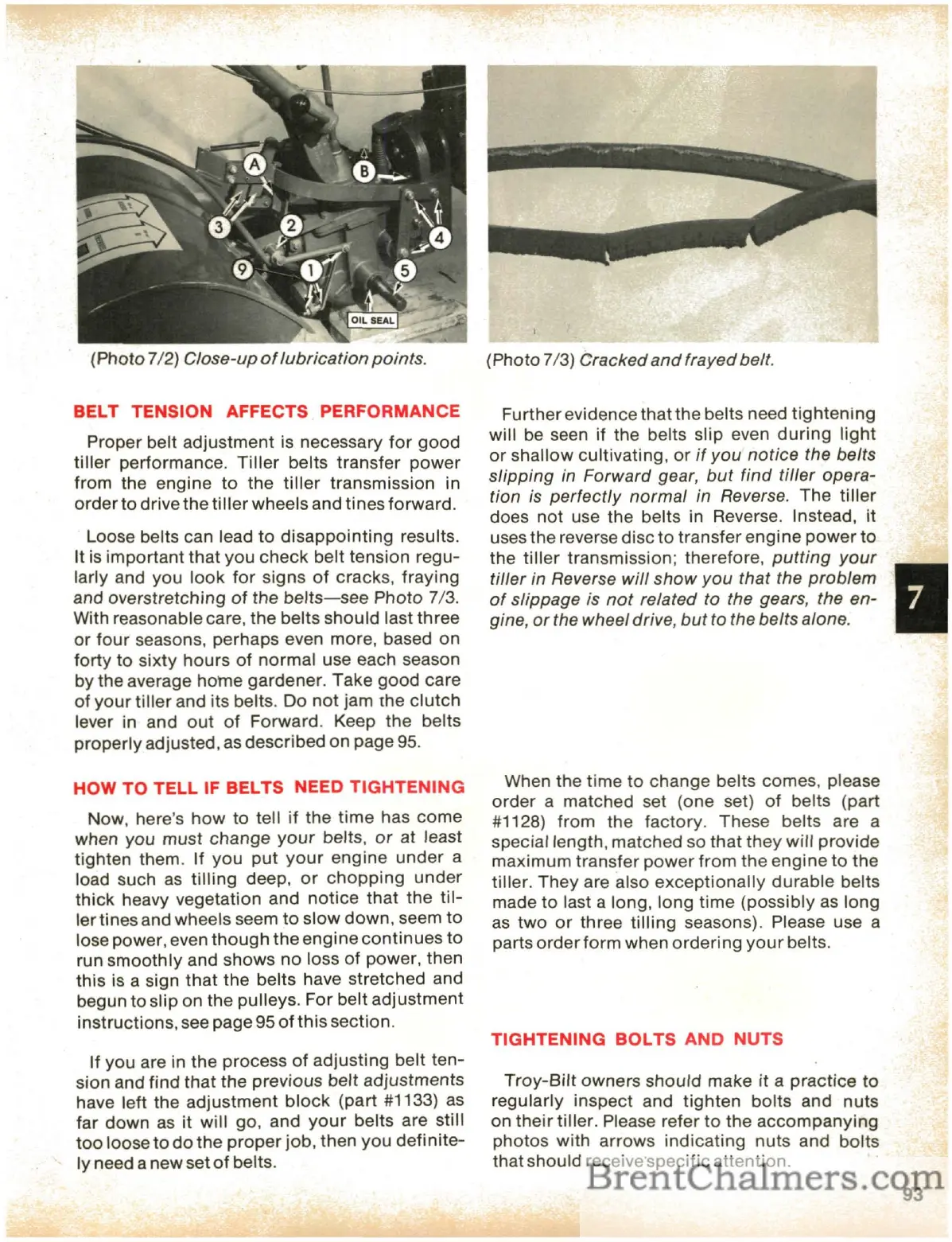

(photo

7/2) Close-up

of

lubrication

points.

BELT TENSION AFFECTS PERFORMANCE

Proper belt adjustment is necessary

for

good

tiller

performance.

Tiller

belts transfer

power

from the engine

to

the

tiller

transmission in

orderto drivethe

tiller

wheels and tines forward.

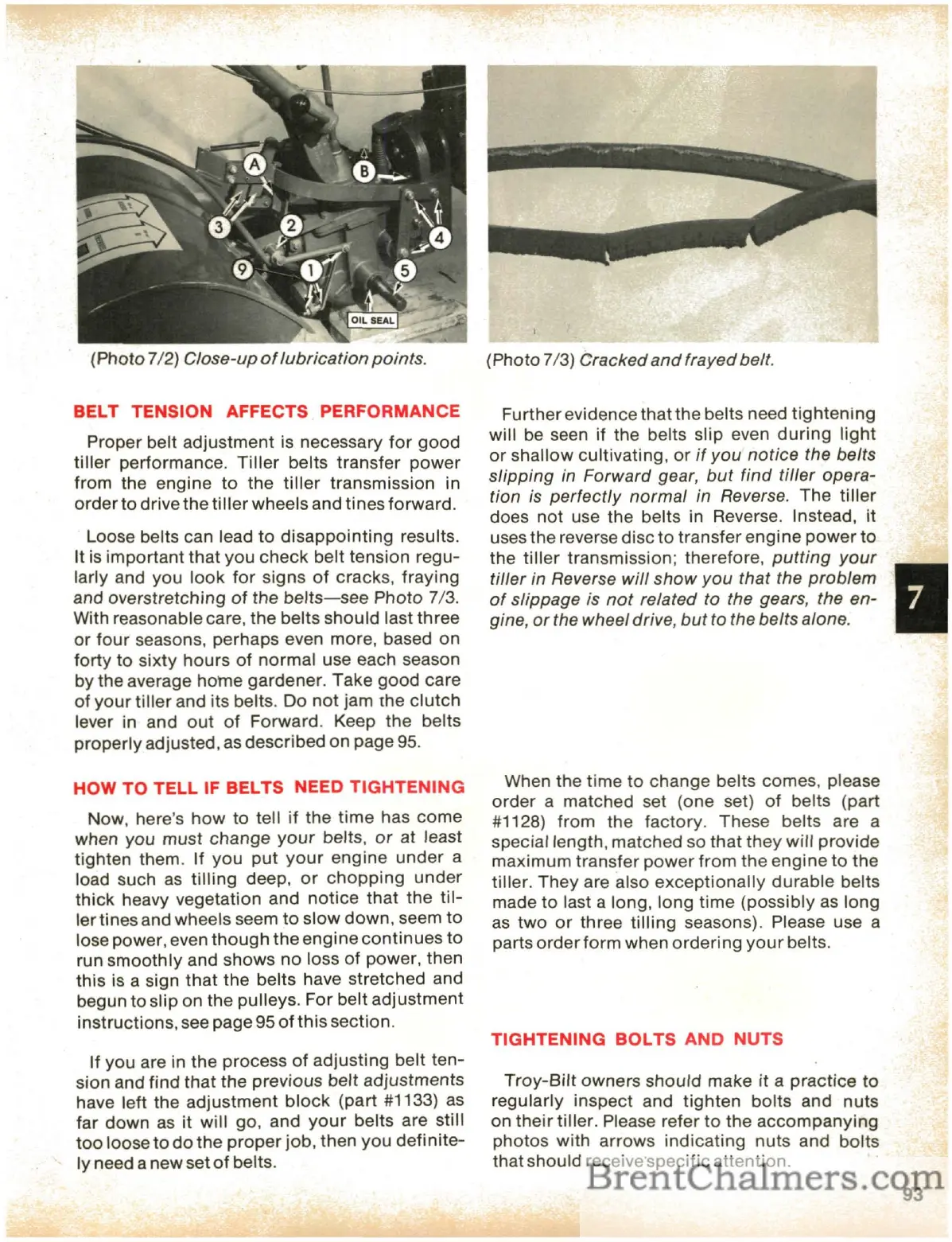

Loose belts can lead

to

disappointing

results.

It is important that you

check

belt tension regu-

larly and you

look

for

signs

of

cracks,

fraying

and overstretching

of

the

belts-see

Photo

7/3.

With reasonable care, the belts should last three

or

four

seasons, perhaps even more, based on

forty

to

sixty

hours

of

normal

use each season

by the average

home gardener. Take

good

care

of

your

tiller

and its belts. Do

not

jam the

clutch

lever in and

out

of

Forward. Keep

the

belts

properly adjusted,

as

described on page

95.

HOW TO TELL IF BELTS NEED TIGHTENING

Now, here's

how

to tell if the

time

has

come

when you

must

change

your

belts,

or

at least

tighten them. If

you

put

your

engine

under

a

load such

as

tilling

deep,

or

chopping

under

thick

heavy vegetation and

notice

that the

til-

lertines

and wheels seem

to

slow

down,

seem

to

lose power, even

though

the

engine

continues

to

run

smoothly

and shows

no

loss

of

power, then

this is a sign

that

the belts have stretched and

begun

to

slip on the pulleys. For belt

adjustment

instructions, see page 95

of

this

section.

If you are in the process

of

adjusting belt

ten-

sion and find

that

the previous belt adjustments

have left the

adjustment

block

(part #1133)

as

far down

as

it

will

go, and

your

belts are still

too

loose to

do

the

proper

job, then

you

definite-

ly

need a new set

of

belts.

(photo

7/3) Cracked

and

frayedbelt.

Furtherevidence that the belts need

tightening

will be seen if the belts slip even

during

light

or

shallow cultivating,

or

if

you

notice

the belts

slipping

in Forward gear,

but

find tiller opera-

tion

is

perfectly

normal

in Reverse. The

tiller

does

not

use the belts in Reverse. Instead, it

uses the reverse disc

to

transfer engine

power

to

the

tiller

transmission; therefore,

putting

your

tiller in Reverse

will

show

you that the problem

of

slippage is

not

related to the gears, the en-

gine,

or

the wheel drive,

but

to the belts alone.

When the time

to

change belts comes, please

order a matched set (one set)

of

belts (part

#1128) from the factory. These belts are a

special length, matched so

that

they

will

provide

maximum transfer

power

from

the

engine

to

the

tiller.

They

are also

exceptionally

durable

belts

made to last a long, long

time

(possibly as long

as

two

or

three

tilling

seasons). Please use a

parts

order

form

when

ordering

your

belts.

TIGHTENING BOLTS AND NUTS

Troy-8i1t owners

should

make

it

a practice

to

regularly inspect and

tighten

bolts

and

nuts

on

their

tiller. Please refer

to

the

accompanying

photos with arrows

indicating

nuts and bolts

thatshould receive'specific attention.

93

Loading...

Loading...