I

(Photo 87144)

Swivel

on

eccentric.

(Photo 8/143)

Bolt

to

end

cap.

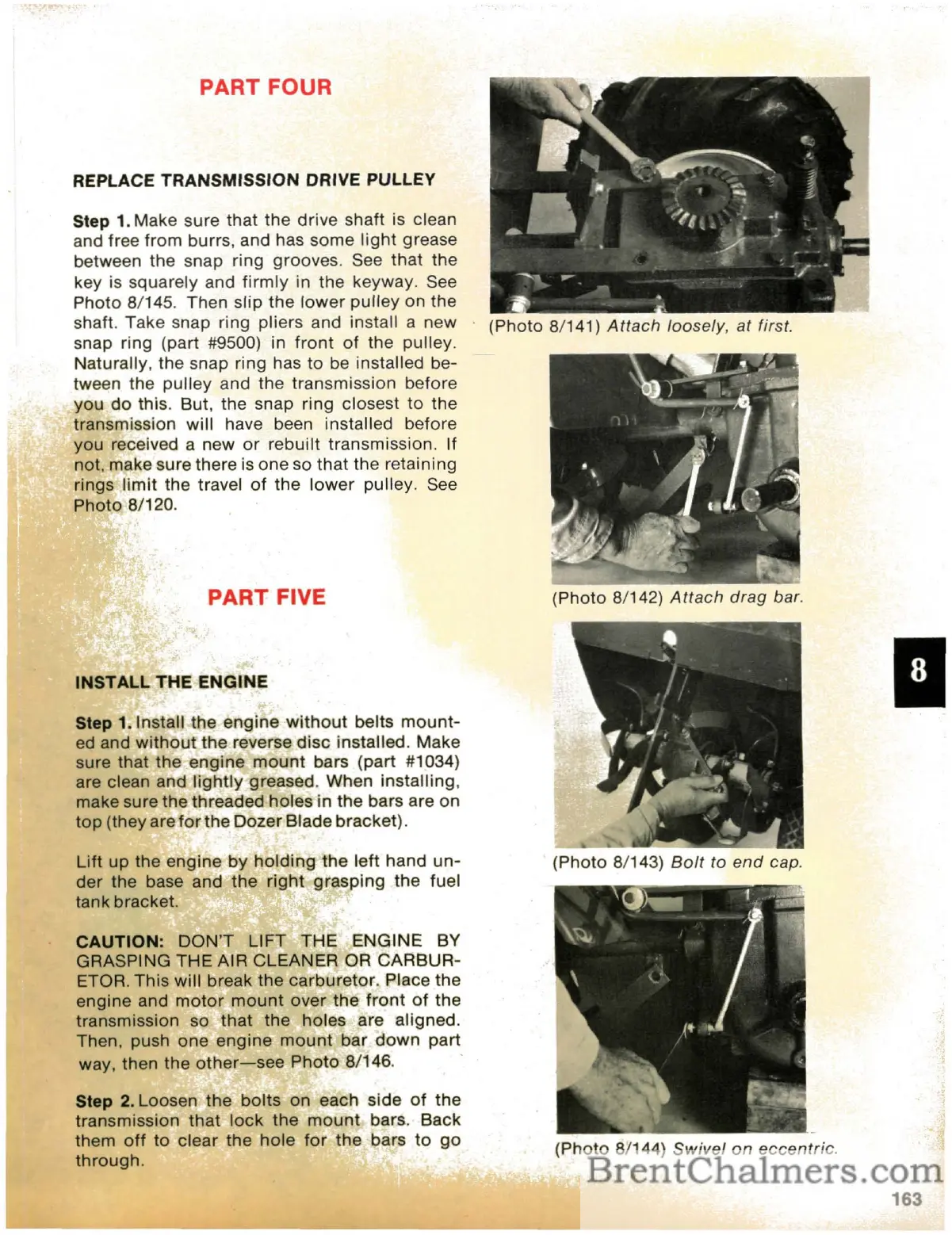

(Photo 8/142)

Attach

drag bar.

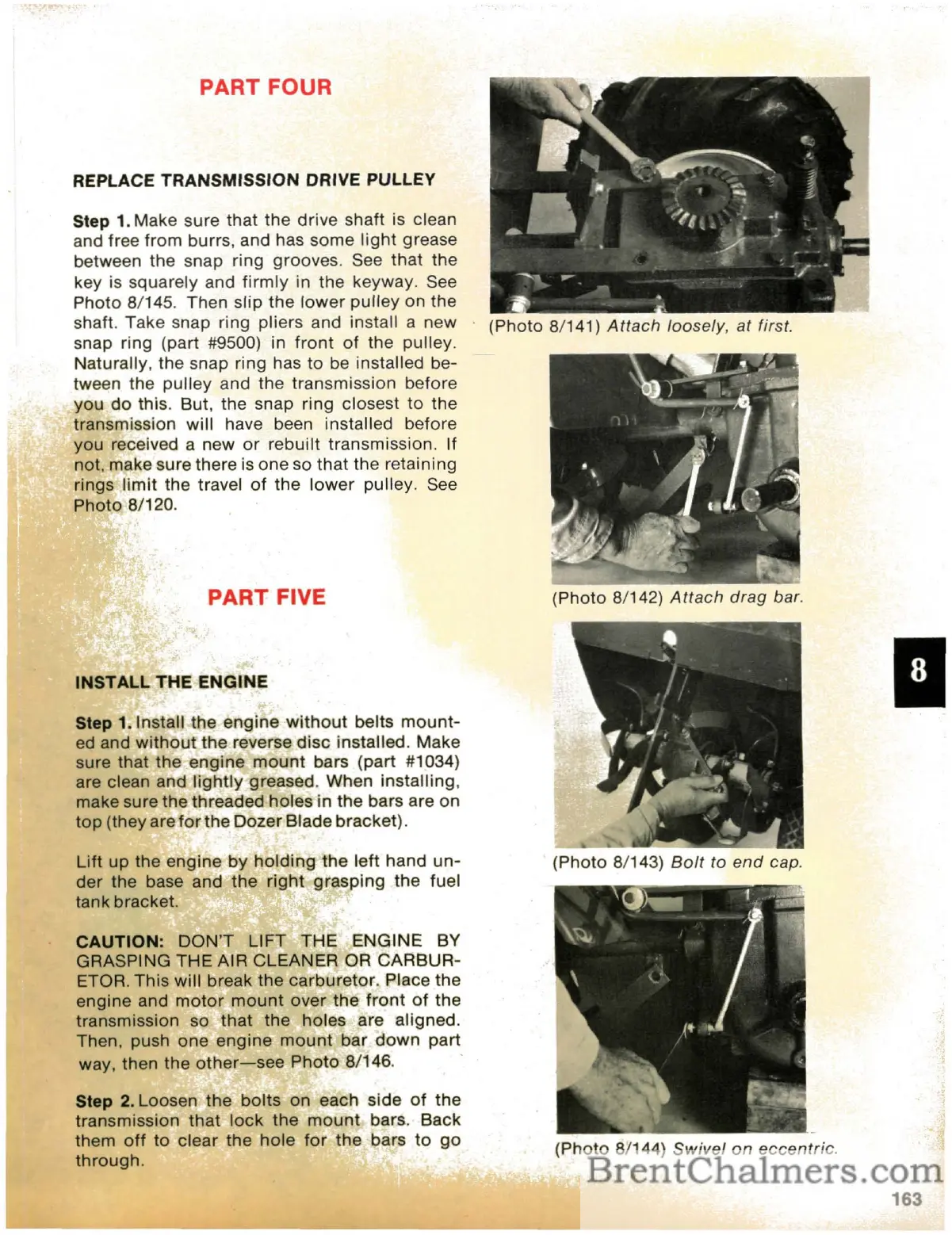

(Photo 8/141) Attach loosely, at first.

PART FIVE

CAUTION:

DON'T

LIFT THE ENGINE BY

GRASPING

THE

AIR CLEANER OR

CARBUR-

ETOR. This will break the carburetor. Place the

engine and

motor

mount

over

the

front

of

the

transmission so

that

the holes are aligned.

Then, push

one

engine

mount

bar

down

part

way, then

the

other-see

Photo 8/146. .

Step

2.

Loosen

the

bolts

on each side

of

the

transmission

that

lock

the

mount

bars. Back

them

off

to

clear

the hole

for

the

bars

to

go

through.

Lift

up

the engine

by

holding

the

left hand

un-

der

the base and

the

right

grasping

the

fuel

tank bracket.

PART FOUR

INSTALL THE ENGINE

Step 1. Install the engine

without

belts

mount-

ed and

without

the

reverse

disc

installed. Make

sure that the engine

mount

bars (part #1034)

are clean and

lightly

greased. When installing,

make sure the threaded holes in the bars are on

top

(they are

for

the Dozer Blade bracket).

Step 1. Make sure that

the

drive shaft is clean

and free

from

burrs, and has some

light

grease

between

the

snap ring grooves. See

that

the

key is squarely and

firmly

in the keyway. See

Photo

8/145. Then slip the

lower

pUlley on the

shaft. Take snap ring pliers and install a new

snap ring (part

#9500) in

front

of

the pulley.

Naturally, the snap ring has

to

be

installed be-

tween the

pulley

and the transmission before

you

do

this. But, the snap ring closest to the

transmission will have been installed before

you received a new

or

rebuilt transmission. If

not, make sure there

is

one so

that

the retaining

rings

limit

the travel

of

the

lower

pulley. See

Photo

8/120.

REPLACE TRANSMISSION DRIVE PULLEY

163

Loading...

Loading...