(Photo 7/5) Tighten

drag

bar

to tiller.

(Photo 7/4) Tighten Forward/Reverse Lever.

Finally,

occasionally

check

the

nuts

and

bolts

that

fasten the tines. Make sure

they

are

tight.

On

occasion, remove

the

tine

holder

on

the

left side so

that

you can reach

the

tiller

hous-

ing

cover

(part

#1023) and

check

the five

socket

head screws

holding

that

cover

in

place-see

Photo 7/9.

You especially

should

make certain

that

those five

socket

head screws are

tight

and

that

the cover is snug and

shows

no

sign

of

any

ap-

preciable oil leak. A small

amount

of

"wetness"

with

oil at

that

point

on

the

cover

is

nothing

to

get excited about. A

genuine

loss

of

oil

should

receive attention at once.

It

is

also a

good

idea

to

check

the

reverse

fi-

ber

disc

(part #1072) and make sure

that

the

mounting

bolt

attaching

it

to

the

pulley

is

firmly

threaded

in-see

Photo 7/10.

CHECK

THE

PARTS FOR WEAR

The

following

parts

should

be

checked

regu-

larly

to

determine

if

there is

any

adverse wear

tn

the first few hours

of

operation. Thereafter,

they

should be checked regUlarly

to

make sure

that

they

have

not

worn

out.

Check

for

wear

of

belts (see Page 93), the reverse

disc

(see page

104), the drag bar

for

the

depth

regulator,

til-

ler tines (see Photo 7/11), and oil seals

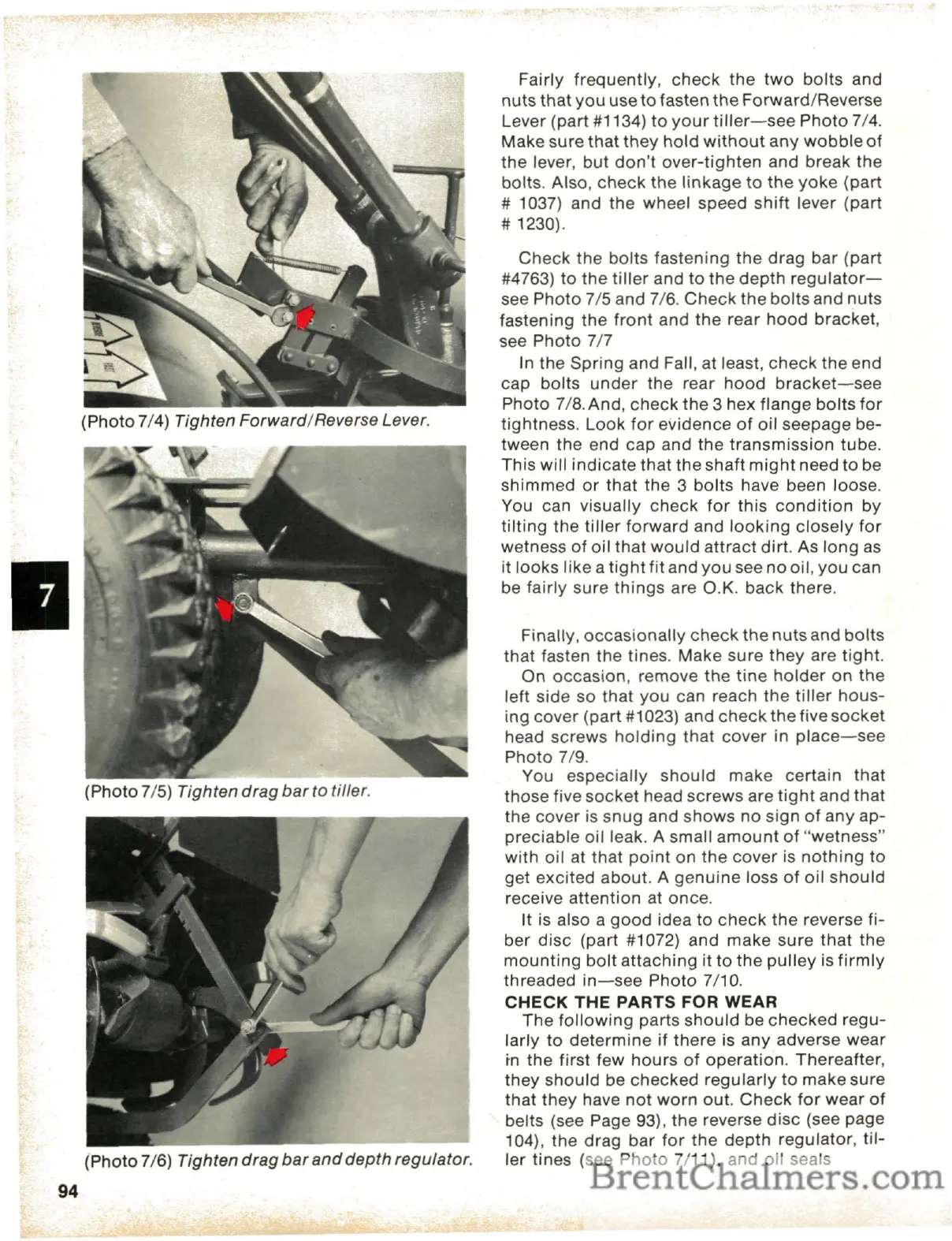

Fairly frequently,

check

the

two

bolts

and

nuts

that

you

use

to

fasten

the

Forward/Reverse

Lever (part #1134)

to

your

tiller-see

Photo

7/4.

Make sure

that

they

hold

without

any

wobble

of

the lever, but

don't

over-tighten

and break the

bolts. Also,

check

the

linkage

to

the

yoke

(part

# 1037) and the wheel speed

shift

lever (part

# 1230).

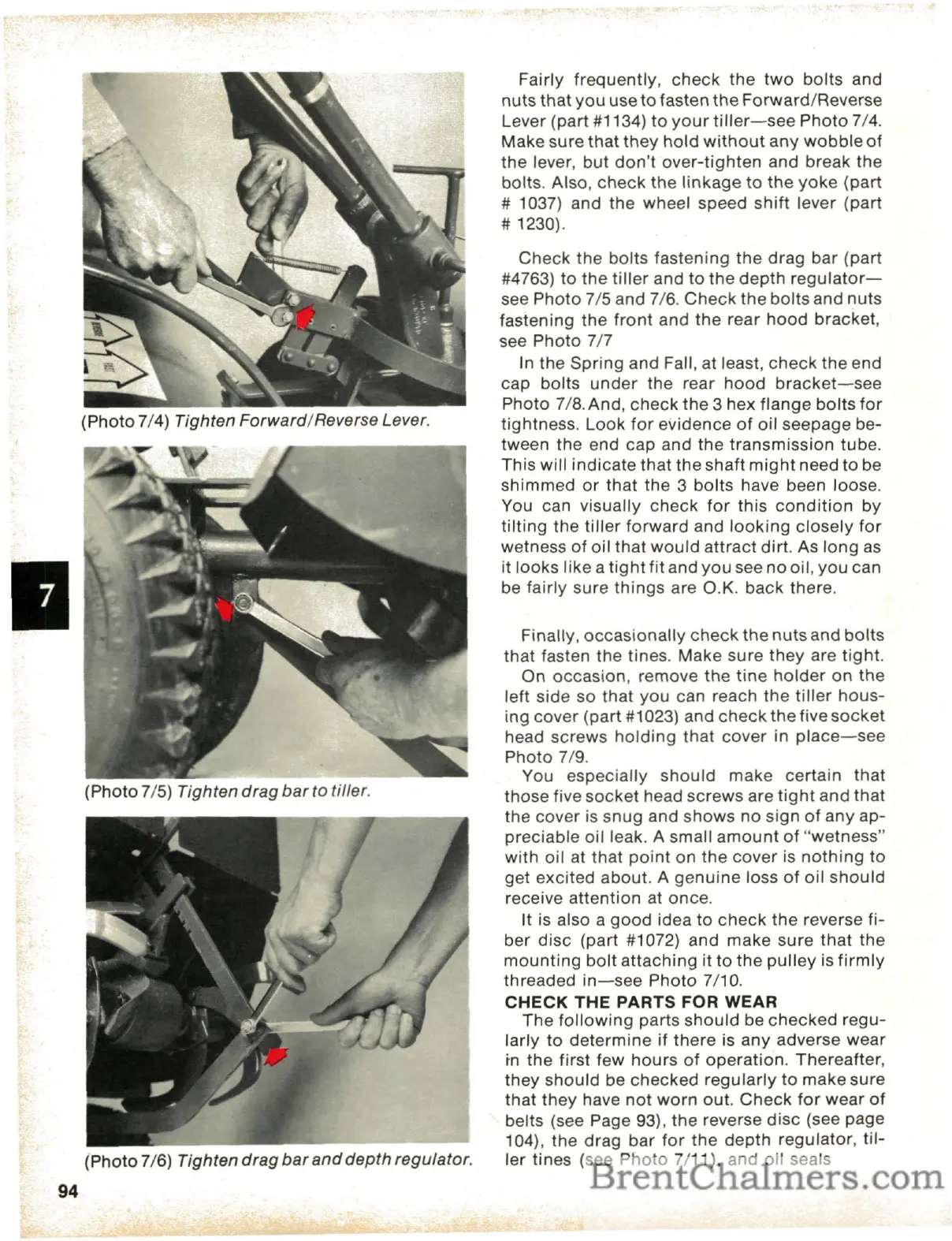

Check

the bolts fastening

the

drag

bar (part

#4763)

to

the

tiller

and

to

the

depth

regulator-

see Photo 7/5 and 7/6.

Check

the

bolts

and nuts

fastening the

front

and

the

rear

hood

bracket,

see Photo 7/7

In the Spring and Fall, at least,

check

the end

cap bolts

under

the rear

hood

bracket-see

Photo 7/8. And,

check

the

3 hex

flange

bolts

for

tightness. Look

for

evidence

of

oil seepage be-

tween the end cap and the

transmission

tube.

This will indicate

that

the

shaft

might

need

to

be

shimmed

or

that

the 3 bolts have been loose.

You can visually

check

for

this

condition

by

tilting

the

tiller

forward

and

looking

closely

for

wetness

of

oil

that

would

attract

dirt. As

long

as

it looks like a

tight

fit and

you

see

no

oil,

you

can

be fairly sure

things

are O.K. back there.

(Photo 7/6)

Tighten

drag

bar

and

depth regulator.

94

II

Loading...

Loading...