Operating & Mounting instructions – 8 074 143.03/03 – Page 31

Parameters

PID reference value

The reference value is selected using parameter A001. The following values can be used as

reference source:

Reference value Settings Standardization

Potentiometer built-in A001 = 00 0...100 %

Parameter value F001 A001 = 02 0...100 % x Parameter A075

Multispeeds A020...A035 0...100 % x Parameter A075

Analog input O (0...10 V) A001 = 01 0...100 % (independent from A011...A014

Analog input OI (4...20 mA) 0...100 % or A101...A104)

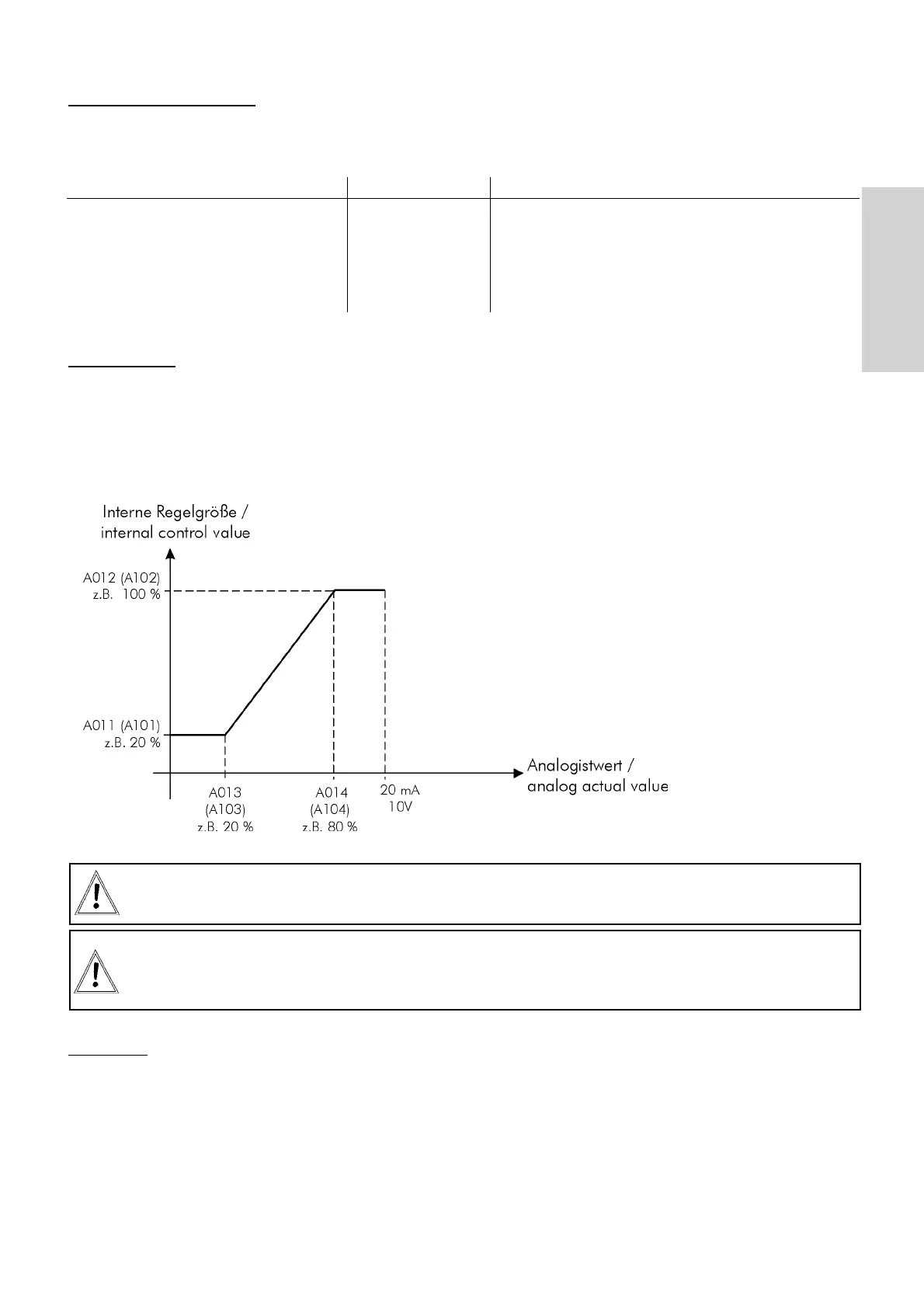

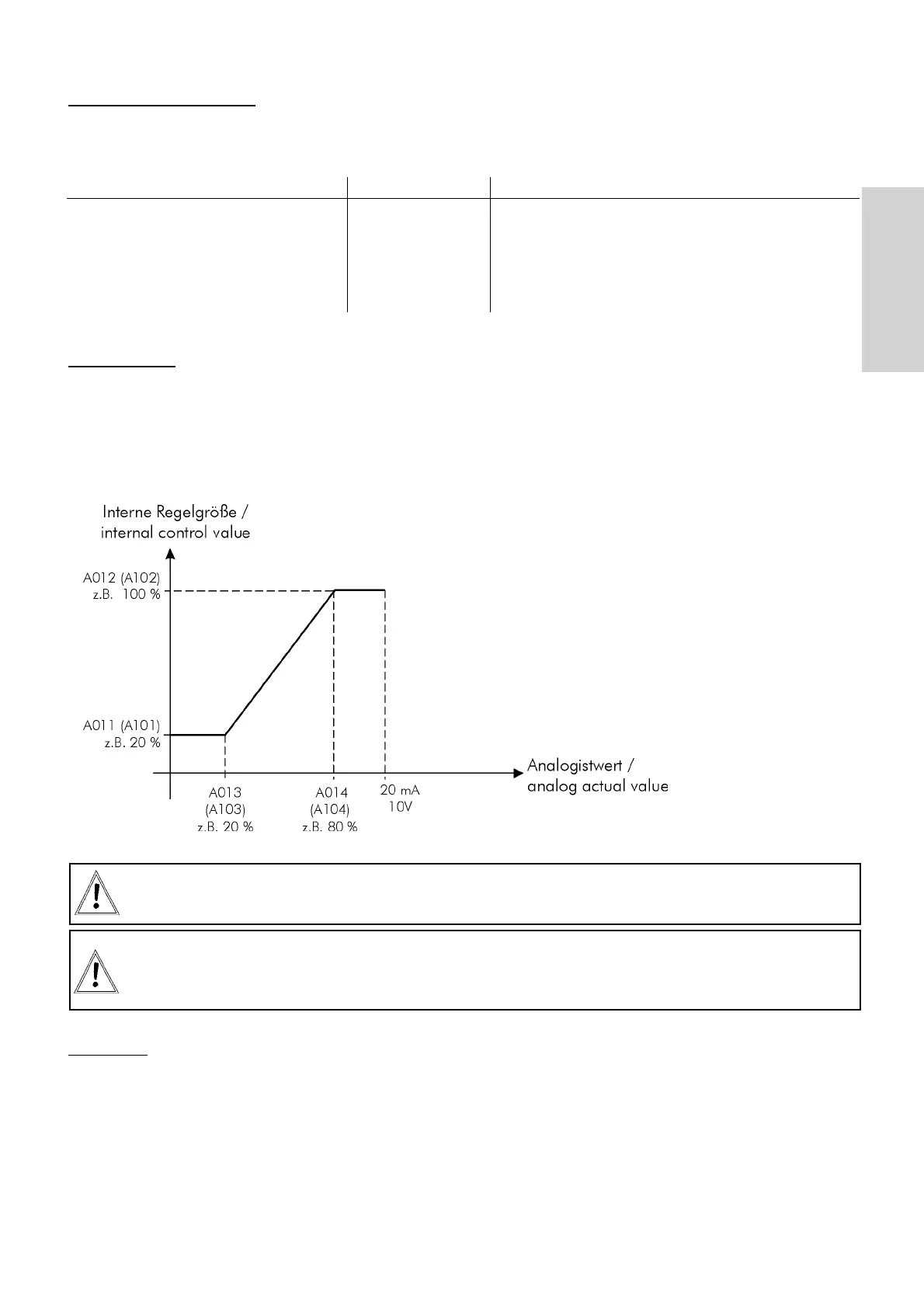

Actual value

One of the two analog inputs (O or OI) can be used as actual value input (selectio with A076).

The actual value registration is adjusted using the analog input function.

See parameters A011...A014 or A101...A104.

The settings of parameters A011 and A012 are changed by activating the PID controller (A071)

from Hz to % and by setting parameter A075 to process values.

Note:

By using the PID controller, the digital function “Automatic reference value (4..20 mA)” is not available!

Note:

Because of the influence of parameter A071 to the scaling of the reference and actual value, it is

important to change this parameter before changing any other!

Displays

Parameter d004 allows the display of the actual value, parameter F001 displays the reference value

on the LED. This values can be converted to process values using the display factor A075.

If parameter F001 is selected, the current PID reference value is displayed. It is not updated conti-

nuously.

The actual value display (parameter d004) is updated continuously.

Loading...

Loading...