Operating & Mounting instructions – 8 074 143.03/03 – Page 88

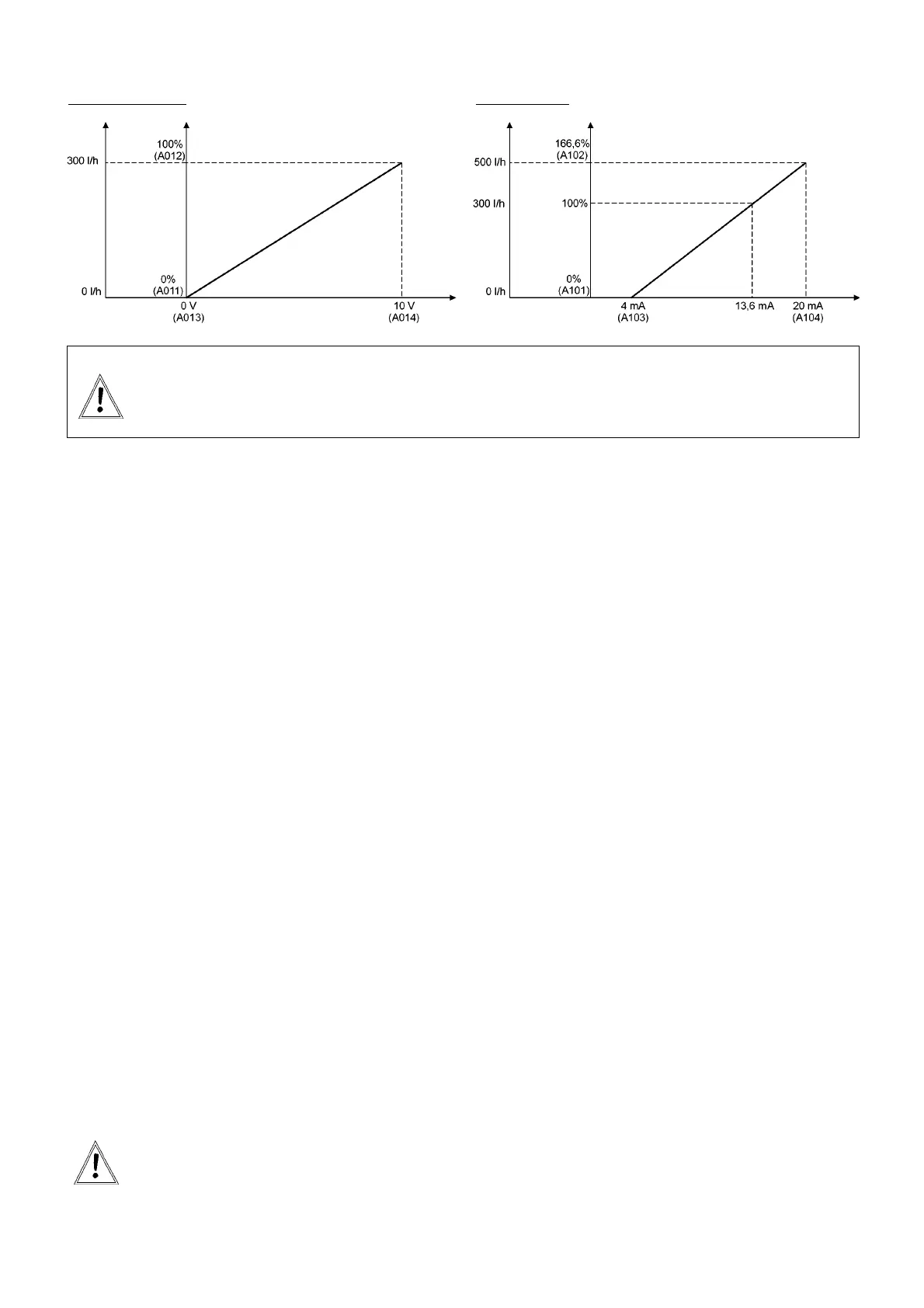

Reference value: Actual value:

Remark:

In order to ensure a correct control process within the whole PID range, the feedback value

must be able to exceed the reference value.

(A deviation is absolutely necessary in order to achieve a control action !)

To adjust the acutal value input (0...500 l/h) to the reference value input (0...300 l/h), it is necessary

to synchronize the actual value at the current input with parameter A101...A104.

Therefore, parameter A102 must be set to 500 l/h (166,6 %), so that an actual value of 300 l/h

corresponds with an reference value of 100 %.

Parameter adjustments:

A001 = 01 Reference value via control terminals

A002 = 01 Control command via digital input

A071 = 01 PID controller active

A075 = 3,0 Scale conversion

A072 = 1,0 P - gain

A073 = 1,0 s I - gain

A074 = 0,0 s D - gain

A011 = 0 l/h Adaptation of the analog ref. value

A012 = 300 l/h

A013 = 0 %

A014 = 100 %

A101 = 0 l/h Adaptation of the analog actual value

A102 = 500 l/h

A103 = 0 %

A104 = 100 %

F002 = appr. 3 s Adjust acceleration time

F003 = appr. 5 s Adjust deceleration time

C001 = 18 RS Reset on digital input 1

C021 = 04 PID deviation signal on terminal 11

C044 = 20 % maximum controller deviation as warning signal 20 %

A062 = 10 Hz Minimum frequency

After setting parameter A062 to 10 Hz, the frequency inverters displays the alarm message

W025. The PRG-LED starts flashing until the inverter is started. The alarm means, that the ref.

value is lower than the minimum frequency.

Loading...

Loading...