Operating & Mounting instructions – 8 074 143.03/03 – Page 87

Connection

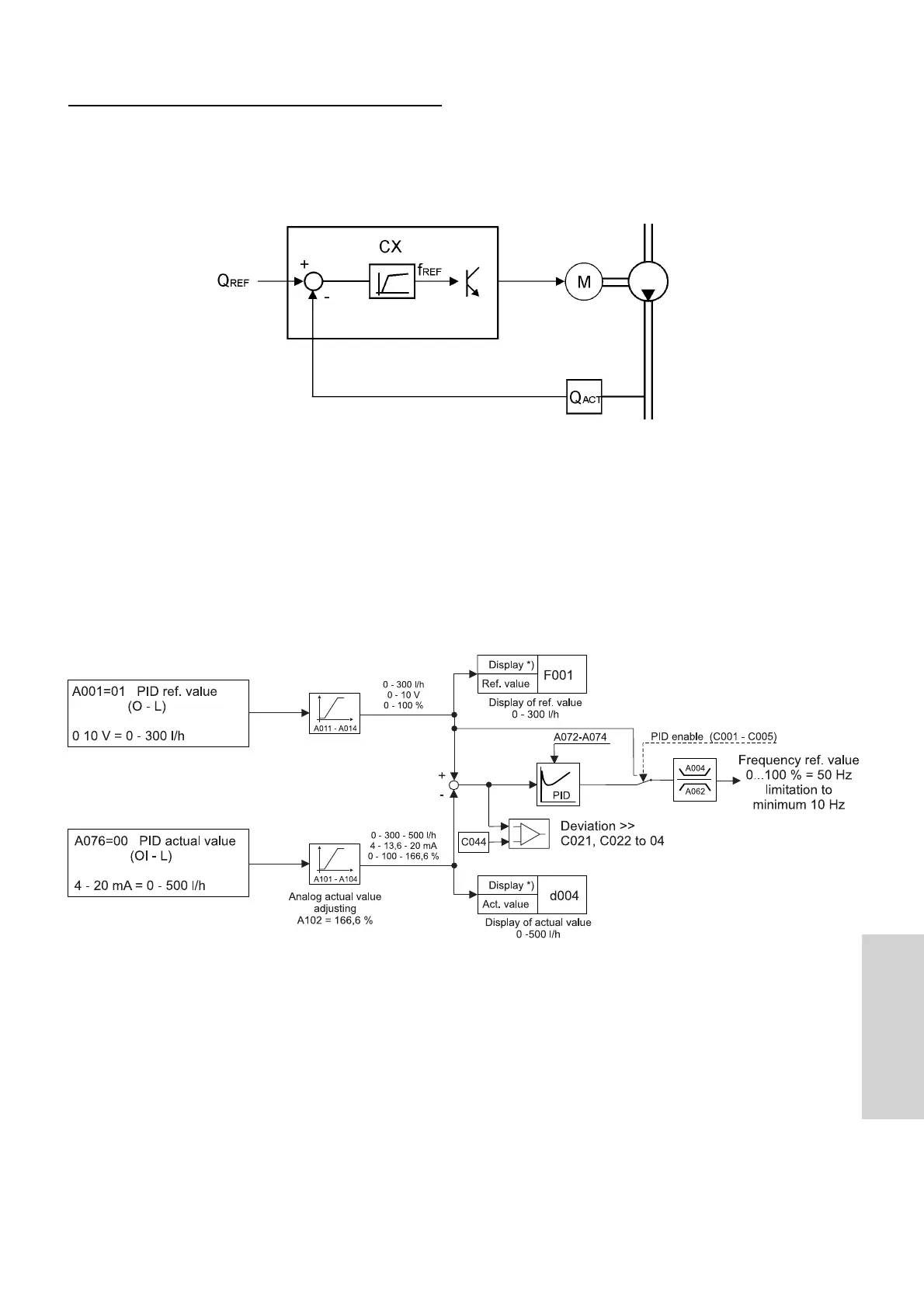

Operation via integrated PID controller

Setting example: flow control

A flow rate control should be set up with the internal PID controller of the >pDRIVE< CX .

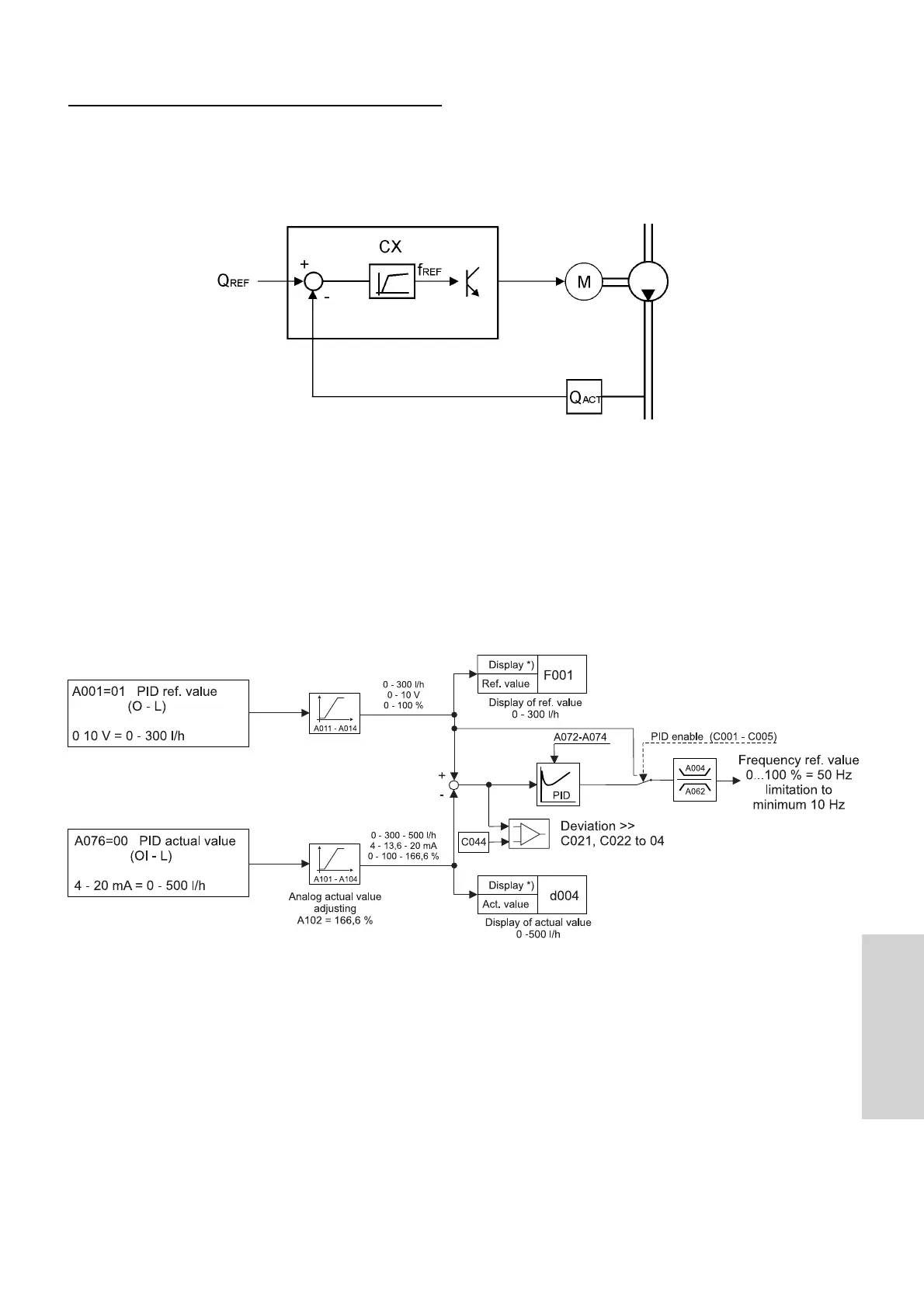

The reference value can be set via voltage input: 0...10 V = 0...300 l/h

The actual value is recorded by a data recorder 0...500 l/h = 4...20 mA.

In the event of PID deviations greater than 20 %, a warning signal must be generated.

The minimum frequency of 10 Hz must not be undercut.

The reference and actual values for the controller must be displayed in process sizes:

300 l/h =100 % control size

Control diagram

*) For the proper setting of the reference value, A075 = 3,00 is selected. Thus, 100 % PID ref.

value is represented as 300 l/h flow rate.

Ref. value needed: 0...100 % correspond to 0...300 l/h

Data recorder: 4...20 mA correspond to 0...500 l/h

Setting A102: 4...13,6 mA = 0...300 l/h = 0...100% intern

20 mA = 500 l/h = 166,6% intern → A102 = 166,6 %

Scale conversion A075: 3,0 (100% x 3,0 = 300 l/h)

Loading...

Loading...