8 ZXP Series 7 Card Printer Service Manual P1036102-007

Theory of Operation

Printing Technologies and Ribbons

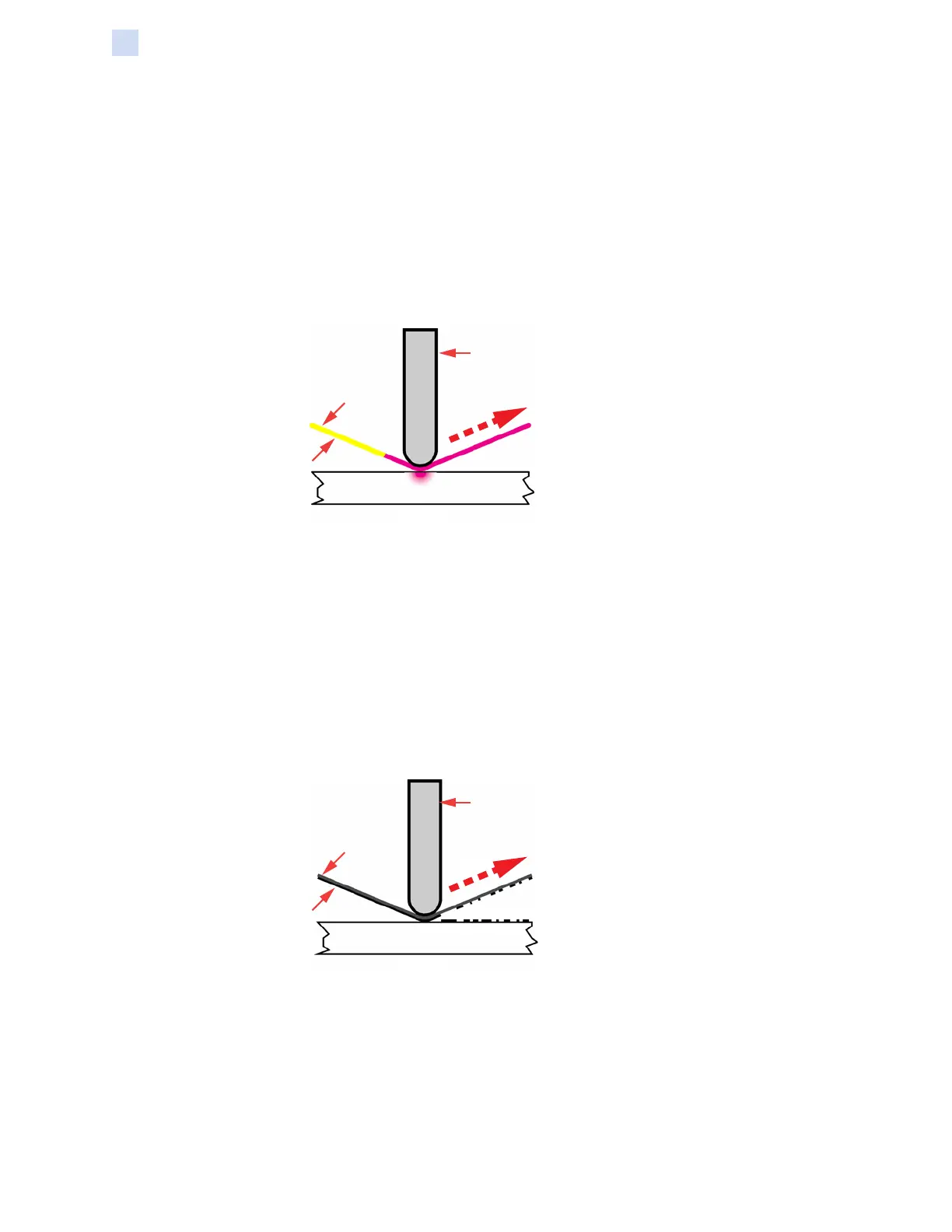

Dye Sublimation Printing

In Dye Sublimation Printing, each printhead heating element is applied voltage at one

of a number of pulse widths.

A wider pulse results in the element getting hotter, which converts more of the dye (at

that pixel location) to a gas and diuses it into the surface of the card (a wider pulse

gives more intense color at that pixel).

This is repeated for each of the dye panels (i.e., Yellow, Magenta, and Cyan), to result

in full-color images.

Card

Printhead

Gaseous dye is

absorbed by the card

Ribbon Carrier

Layer

Ribbon Ink

Layer

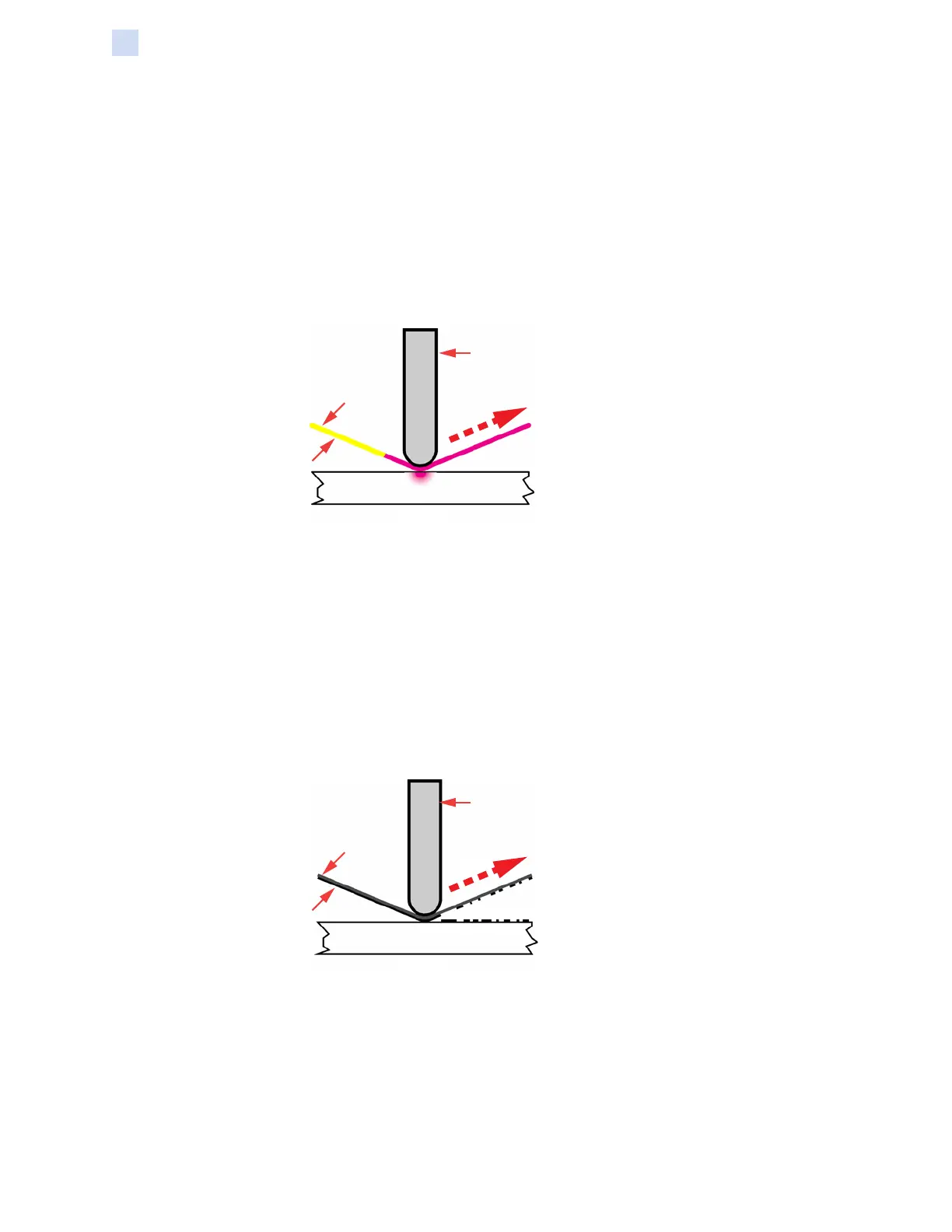

Thermal Transfer Printing

In Thermal Transfer Printing, voltage is either applied or not applied to each printhead

printing element. If voltage is applied, the ink at that location is transferred to the

surface of the card.

Each pixel is either printed (i.e., the ink is transferred to the card) or not; there are no

intermediate levels.

Thermal Transfer printing with a black (K) resin panel is used for printing bar codes,

since contrast between the light and dark areas is the highest and the edges are the

sharpest.

Card

Printhead

Ink is transferred to the

surface of the card

Ribbon Carrier

Layer

Ribbon Ink

Layer

Loading...

Loading...