Electrical installation: input / output 81

Extra incremental encoder

Some applications require the connection of multiple encoders typically when:

• A single axis has multiple encoders on the same motion system to eliminate

mechanical errors (a dual encoder application).

• The drive is required to follow encoder signals given to it from a master encoder

input.

In both cases the drive can support a connection to an extra incremental encoder by

X7 (see page 83) or X8. The default extra incremental encoder input (encoder 2) is

X7.If X7 is occupied as an encoder output and the primary feedback type is one that

does not use the Hall/sin/cos inputs (Incremental encoder without Halls, BiSS-B, SSI,

EnDat 2.2, Smart Abs or resolver), the extra incremental encoder also can be

connected to X8.

Note: In Mint, this extra encoder input (encoder 2 on X8) is available only when

connector X7 has been configured as an encoder output (see page

84).

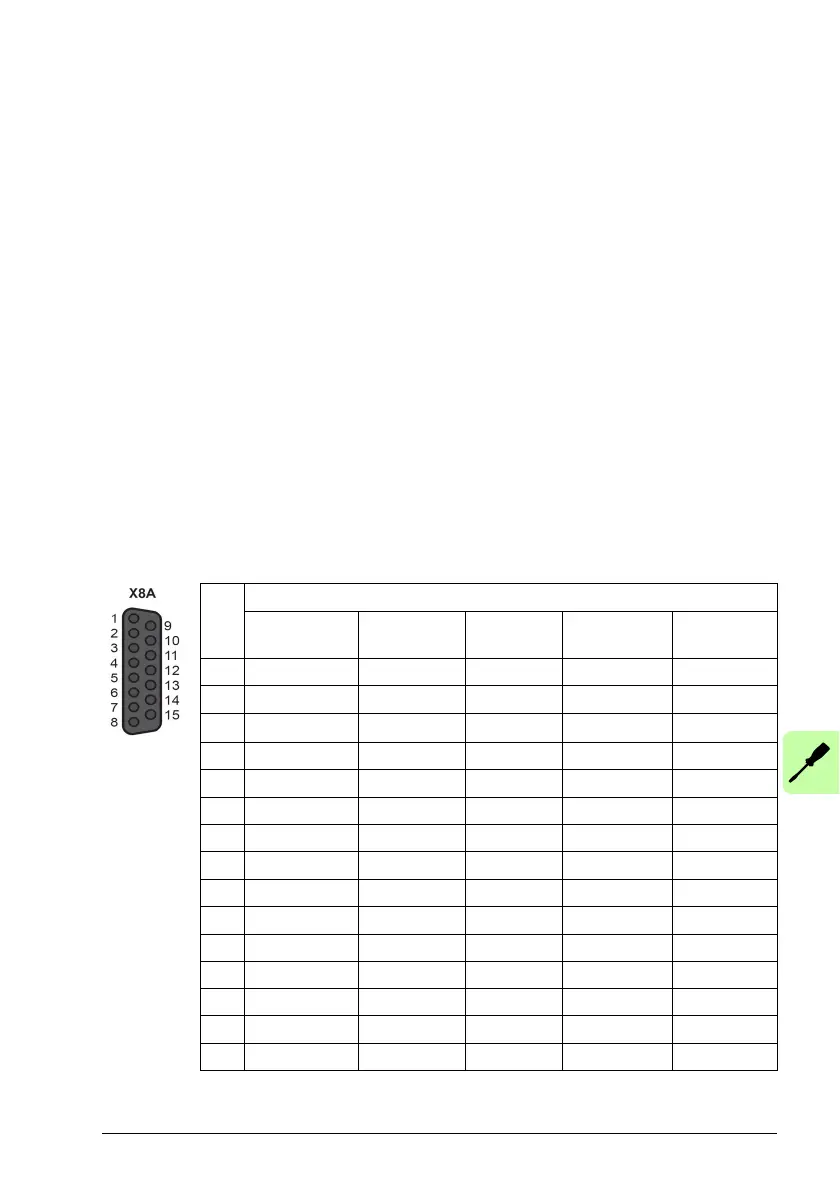

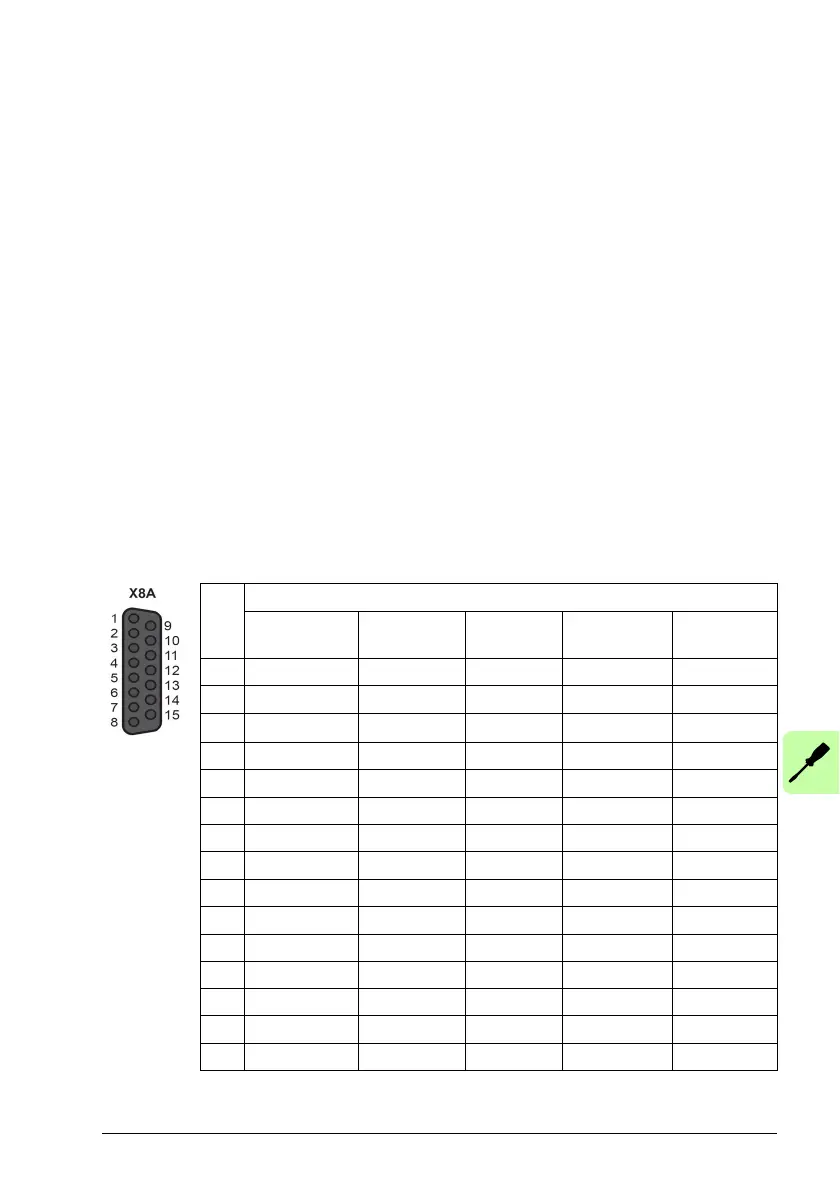

When connector X8 is specified as encode 2, a encoder breakout OPT-MF-200 need

to be mounted to split one 15-pin connector X8 into one 15-pin connectors X8A and

one 9-pin X8B. X8A is connected to motor feedback, while X8B is connected to an

extra incremental encoder (see page

180).

Pin X8A (Primary encoder)

Inc. encoder

without Halls

BiSS-B SSI EnDat 2.2 Smart Abs

1 CHA+ Data+ Data+ Data+ Data+

2 CHB+ Clock+ Clock+ Clock+ (NC)

3 CHZ+ (NC) (NC)

(NC)

(NC)

4 (NC) (NC) (NC) (NC) (NC)

5 (NC) (NC) (NC) (NC) (NC)

6 (NC) (NC) (NC) (NC) (NC)

7 (NC) (NC) (NC) (NC) (NC)

8 (NC) (NC) (NC) (NC) (NC)

9 CHA- Data- Data- Data- Data-

10 CHB- Clock- Clock- Clock- (NC)

11 CHZ- (NC) (NC) (NC) (NC)

12 +5.5 V out +5.5 V out +5.5 V out +5.5 V out +5.5 V out

13 DGND DGND DGND DGND DGND

14 (NC) (NC) (NC) (NC) (NC)

15 (NC) (NC) (NC) (NC) (NC)

Loading...

Loading...