6-2 ApexPro™ Telemetry 2001989-203C

Troubleshooting

General fault isolation

Visual inspection

A thorough visual inspection of the equipment can save time. Small things—

disconnected cables, foreign debris on circuit boards, missing hardware, loose

components—can frequently cause symptoms and equipment failures that may

appear to be unrelated and difficult to track.

The following tests are highly recommended to remove these simple failures as

causes of problems.

Set the ON/OFF switch to the OFF position and disconnect the Receiver System

from its power source.

See Disassembly/assembly on page 7-3. Perform an internal visual inspection of

the components.

Take the time to make all the recommended visual checks (refer to the visual

inspection table below) before starting any detailed troubleshooting procedures.

WARNING

If a USB disk is plugged into the ATS, you need to remove it prior to

rebooting. Otherwise, the system software may not restart.

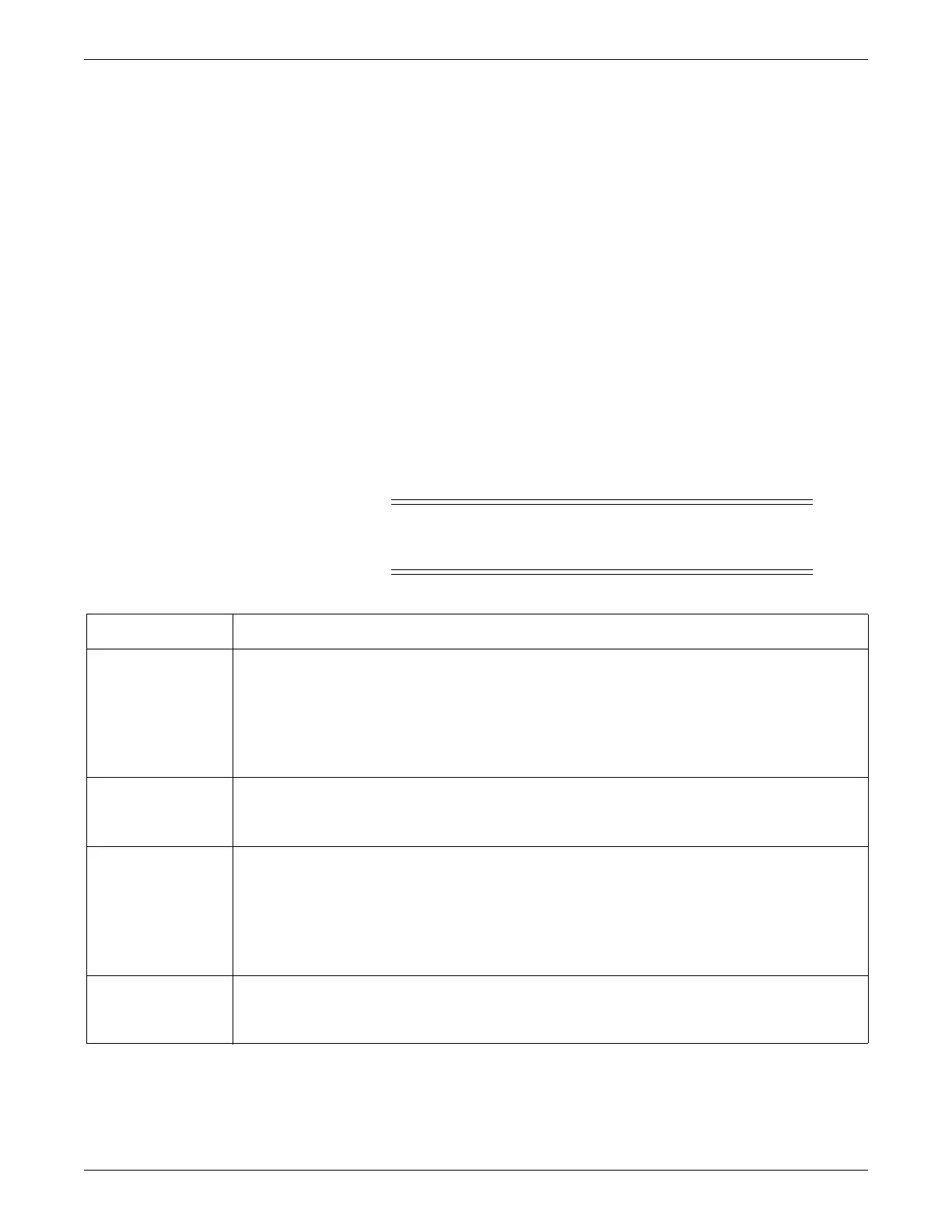

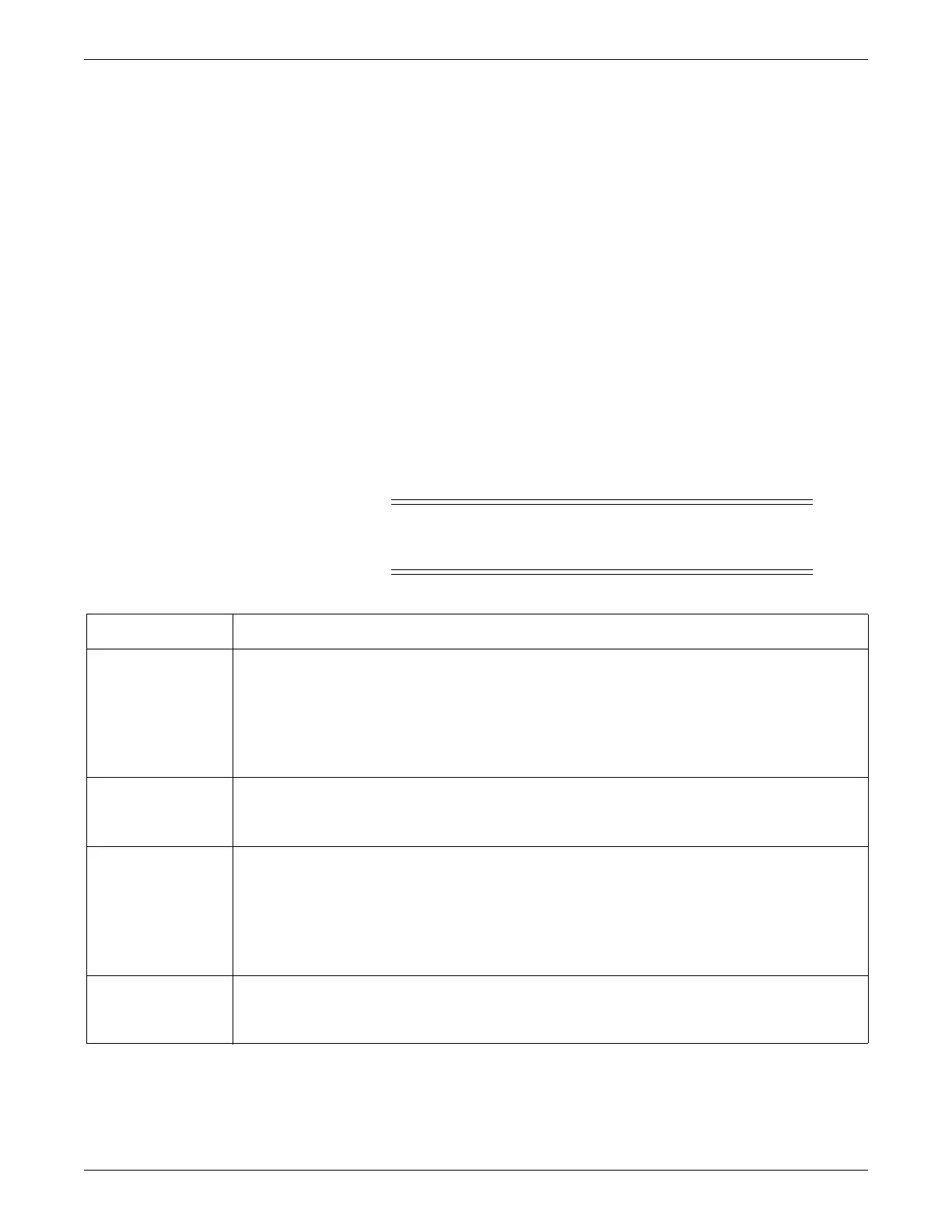

Area Look for the following problems:

I/O connectors and

interface cables

Fraying or other damage.

Bent prongs or pins.

Cracked housing.

Loose screws in plugs.

Excessive cable tension or wear.

Secure mounting hardware.

Internal harnesses and

cables

Excessive tension or wear.

Loose connection.

Strain reliefs out of place.

Circuit boards Moisture, dust, or debris (top and bottom).

Loose or missing components.

Burn damage or smell of over-heated components.

Socketed components not firmly seated.

PCB not seated properly in edge connectors.

Solder problems: cracks, splashes on board, incomplete feedthrough, prior modifications or repairs.

Ground wires/wiring Loose wires or ground strap connections.

Faulty wiring.

Wires pinched or in vulnerable position.

Loading...

Loading...