System bus (CAN / CAN−AUX) configuration

Setting the CAN node address and baud rate

Settings via codes

8

158

EDBCSXA064 EN 3.2

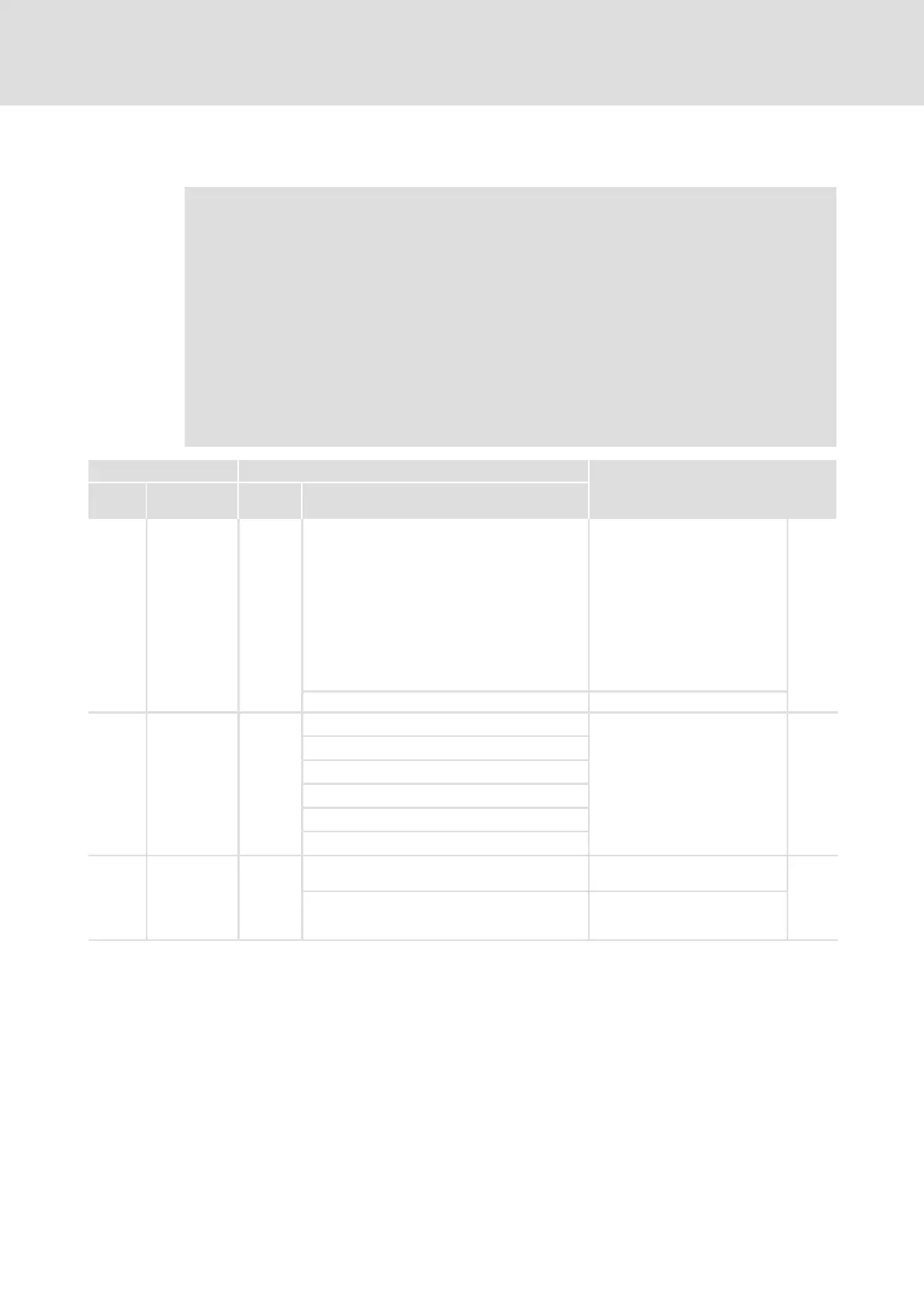

8.1.2 Settings via codes

Note!

ƒ The settings in C0350/C2450 (CAN node address) and C0351/C2451 (baud

rate) are only used if the (address) switches 2 ... 7 of the DIP switch S1 are

switched off (OFF).

ƒ If only one (address) switch 2 ... 7 is switched on (ON), the settings of the DIP

switch S1 usually apply.

ƒ The baud rate (C0351/C2451) must be set identically for all CAN bus nodes.

ƒ If the Lenze setting has been loaded via C0002,

– C0351/C2451 is set = 0 (500 kbits;

– you have to reset the baud rate (C0351/C2451) and the CAN node address

(C0350/C2450).

Code Possible settings IMPORTANT

No. Designation Lenze/

{Appl.}

Selection

C0350 CAN address 32 Node address for CAN bus

interface X4

l This code is not active if one

of the switches 2 ... 7 of the

DIP switch is set to "ON".

( 156)

l After the setting process, a

reset node is required.

l A definite node address must

be assigned to each CAN

node.

156

458

1 {1} 63

C0351 CAN baud rate 0 Baud rate for CAN bus interface

X4

l The baud rate must be set

identically for all CAN nodes.

l This code is not active if one

of the switches 2 ... 7 of the

DIP switch is set to "ON".

l After the setting process, a

reset node is required.

156

0 500 kbps

1 250 kbits/sec

2 125 kbit/s

3 50 kbps

4 1000 kbit/s

C2450 CANa address 1

Node address for CAN bus

interface X14 (CAN−AUX)

156

458

1 {1} 63 This code is inactive if one of DIP

switches 2 ... 7 and switch 1 are

set to "ON".

Loading...

Loading...