System modules

CANaux3_IO (node number 36)

Outputs_CANaux3

13

318

EDBCSXA064 EN 3.2

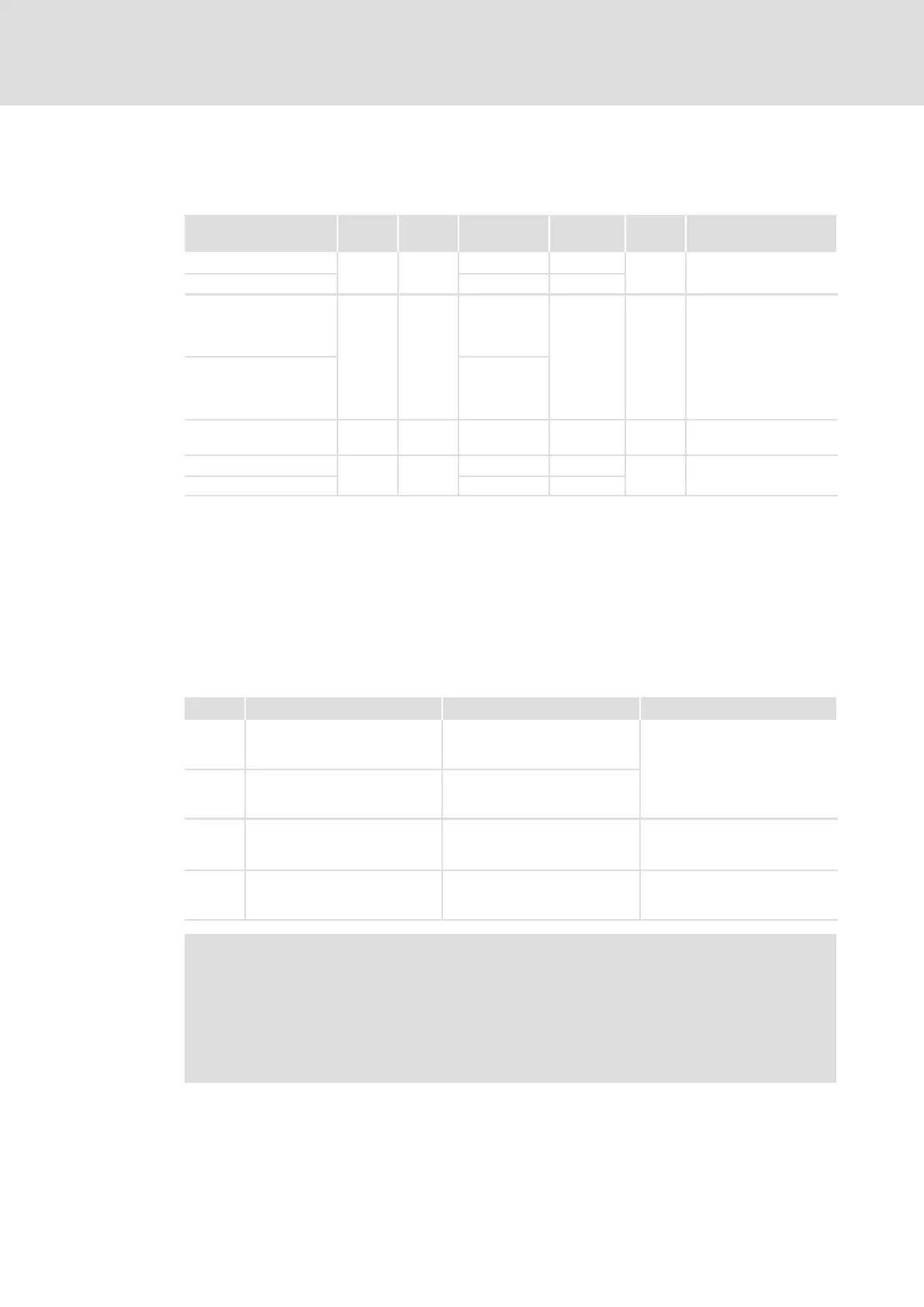

13.14.2 Outputs_CANaux3

System variables

Variable Data

type

Signal

type

Address Display

code

Display

format

Comments

CANaux3_nOutW1_a

integer

analog

%QW36.0 C2493/8

dec [%]

CANaux3_nOutW2_a %QW36.1 C2493/9

CANaux3_bFDO0_b

BOOL binary

%QX36.0.0

˘ ˘

... ...

CANaux3_bFDO15_b %QX36.0.15

CANaux3_bFDO16_b %QX36.1.0

... ...

CANaux3_bFDO31_b %QX36.1.15

CANaux3_dnOutD1_p double

integer

position %QD36.0 ˘ ˘

CANaux3_nOutW3_a

integer analog

%QW36.2 C2493/10

dec [%]

CANaux3_nOutW4_a %QW36.3 C2493/11

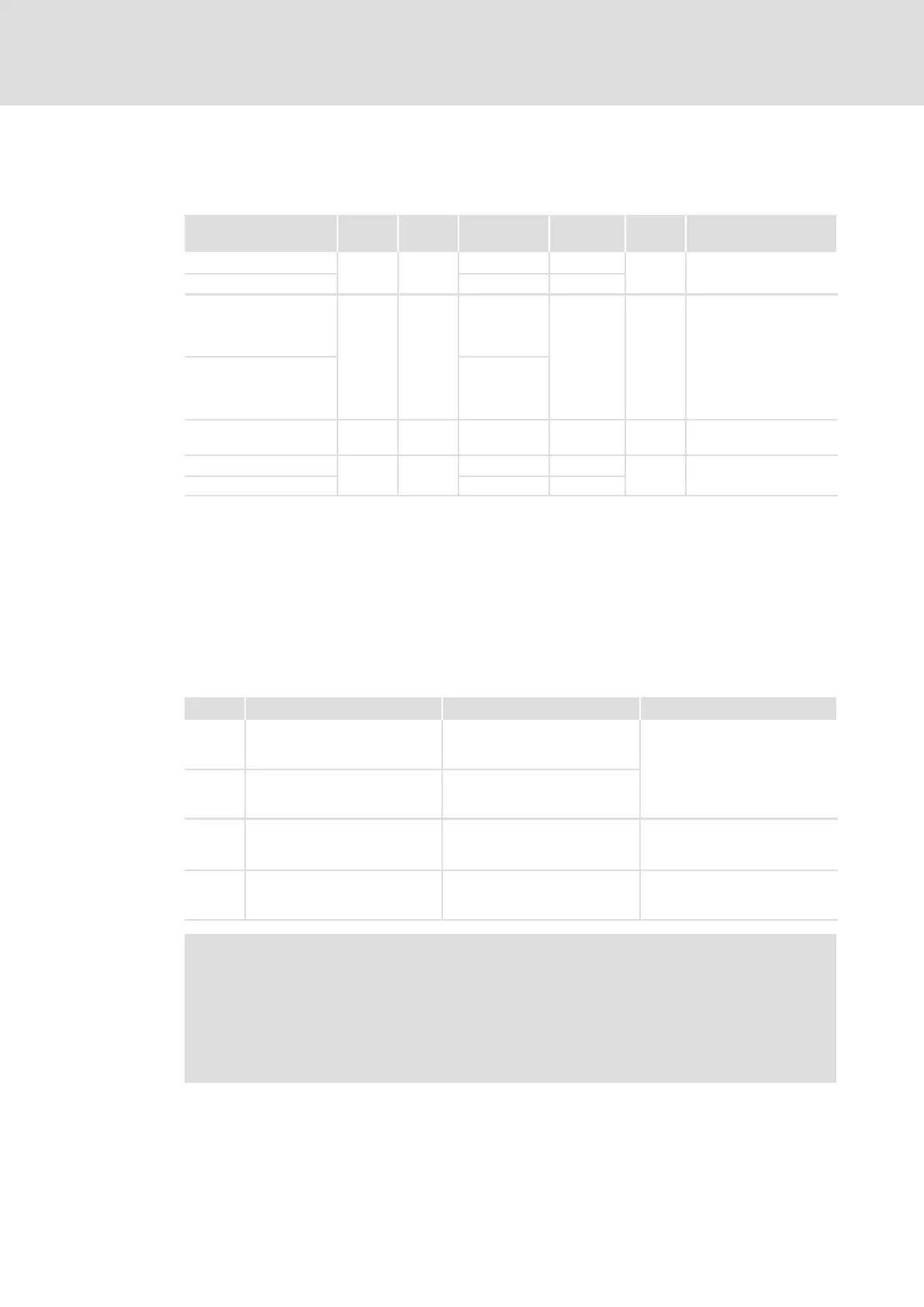

User data

The first 4 bytes of the 8 bytes user data to be sent can be written via several variables of

different data types. According to requirements, data can therefore be transferred from

the PLC program as

ƒ binary information (1 bit)

ƒ status word/quasi−analog value (16 bit)

ƒ angle information (32 bit)

Byte Variable (1 bit) Variable (16 bit) Variable (32 bit)

1, 2 CANaux3_bFDO0_b

...

CANaux3_bFDO15_b

CANaux3_nOutW1_a

CANaux3_dnOutD1_p

3, 4 CANaux3_bFDO16_b

...

CANaux3_bFDO31_b

CANaux3_nOutW2_a

5, 6

CANaux3_nOutW3_a

7, 8

CANaux3_nOutW4_a

Note!

Avoid simultaneous overwriting via different variable types to ensure data

consistency.

If you want to describe e.g. the bytes 1 and 2, either use only the variable

CANaux3_dnOutD1_p, or only the variable CANaux3_nOutW1_a or only the

variables CANaux3_bFDO0_b ... CANaux3_bFDO15_b!

Loading...

Loading...