Appendix

System program organisation units

14

383

EDBCSXA064 EN 3.2

14.4 System program organisation units

System POUs are program organisation units of the "program" type, which by means of a

specific designation adopt the feature of being started subject to an event occurring in the

ECSxA... axis module.

ƒ The program includes max. 1000 instructions for system POUs.

ƒ Unlike tasks or PLC_PRG, system POUs are not run−time monitored by a "watchdog".

ƒ See the following table for special POU names and the related events for starting

the POU:

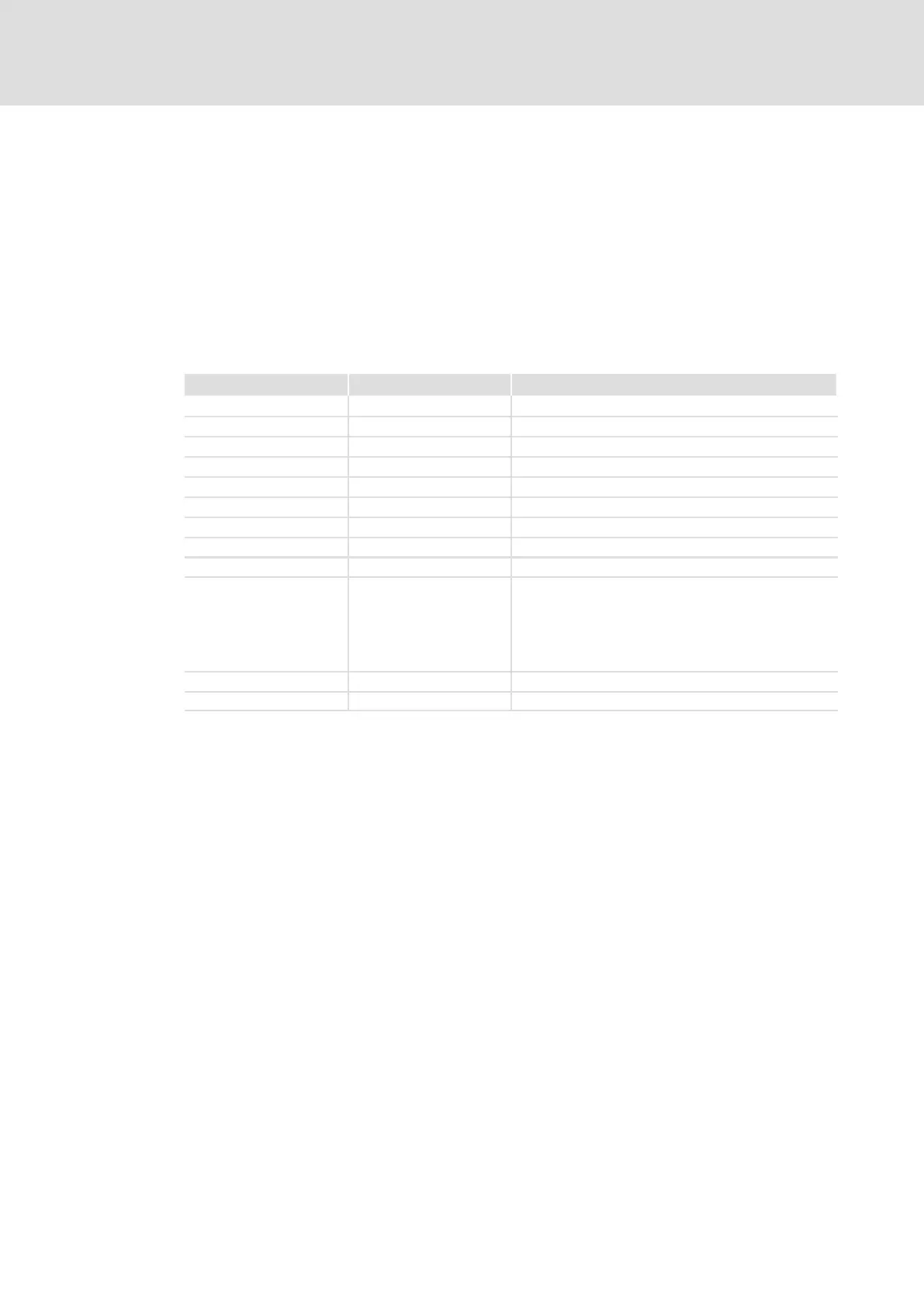

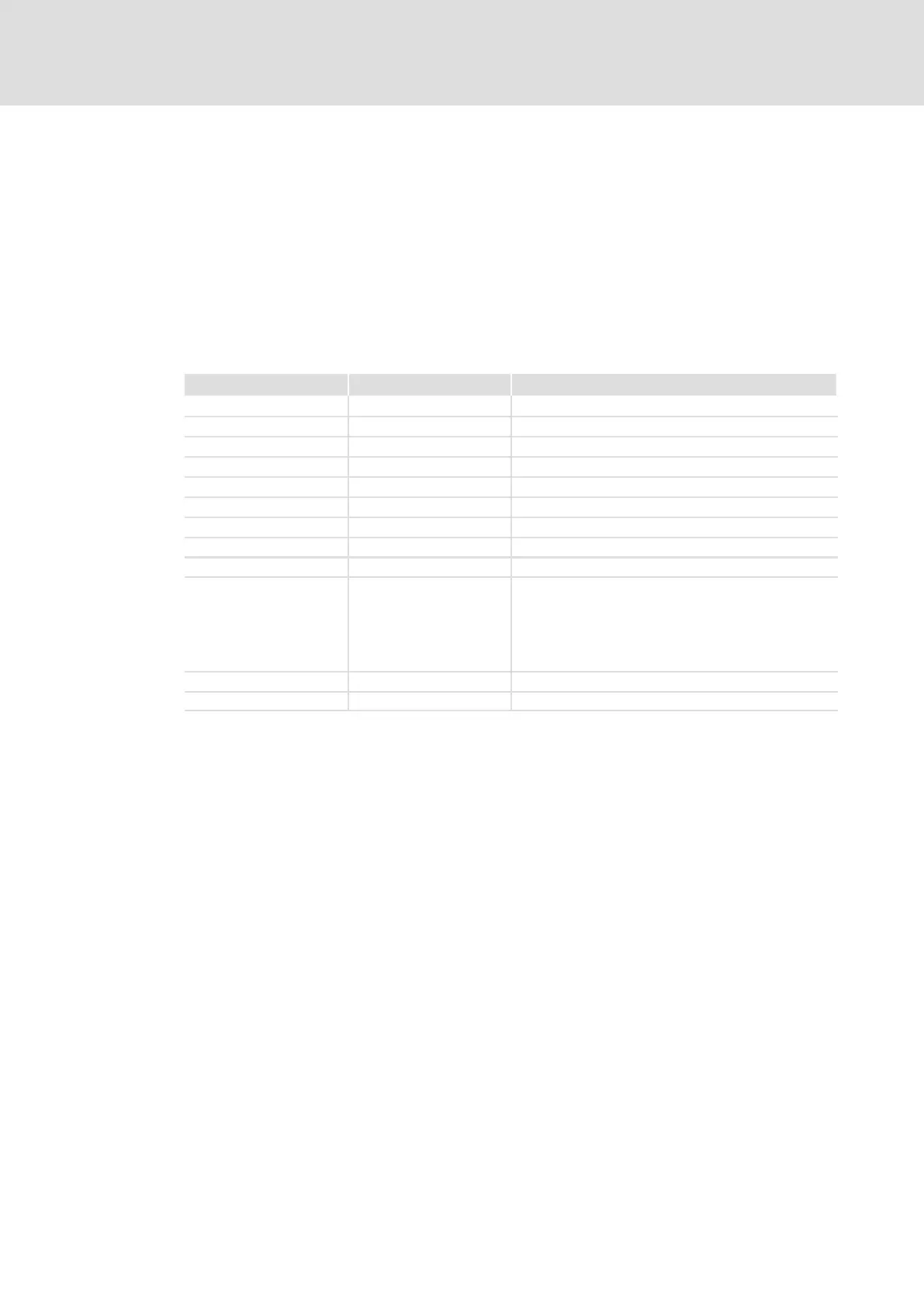

POU name Event for starting POU The POU starts if

PLC_TaskOverrun Task overflow ... the task monitoring time is exceeded.

1)

PLC_RealError Floating−point error ...a floating−point error occurs.

PLC_FailTripping TRIP ...a trip is set.

PLC_WarningTripping Warning ...a warning is activated.

PLC_MessageTripping Message ...a message is indicated.

PLC_FailQspTripping FAIL−QSP ...a FAIL−QSP is activated.

2)

PLC_CANError CAN bus error ... a CAN bus error occurs (e.g. BUS−OFF).

3)

PLC_AIFError AIF bus error ... an AIF bus error occurs.

3)

PLC_Restart Start ... the START command is activated after a STOP.

PLC_ColdStart Cold start ... a RESET, RESET (cold), RESET (original) or a program

download has been activated.

4)

Note: System variables must not be used in

PLC_ColdStart since this can lead to an unexpected

maloperation of the control system (e.g. restart of the

motor).

PLC_Stop PLC stop ... the STOP command is activated.

5)

PLC_Undervoltage LU threshold ... the set LU threshold is fallen below.

1)

The system variable "SYSTEM_bPLCResetAndRun"

does not execute a TRIP reset. Thus, an automatic

restart is not possible in this POU.

Procedure without mains switching:

PLC reset (C2108) => TRIP reset (C0043) => PLC start

(C2108)

2)

Is only called if pulse inhibit is not active.

3)

Only called if all monitoring functions of the

corresponding communication are deactivated.

4)

The CAN/AIF bus is ready after this POU has been

executed.

5)

This POU is not activated by Reset (cold, original).

Tip!

If you need a system POU for an event−controlled start, create a "program"

POU and use the name of this POU as POU name related to the corresponding

event listed in the table.

Loading...

Loading...