Troubleshooting and fault elimination

Fault messages

Causes and remedies

12

246

EDBCSXA064 EN 3.2

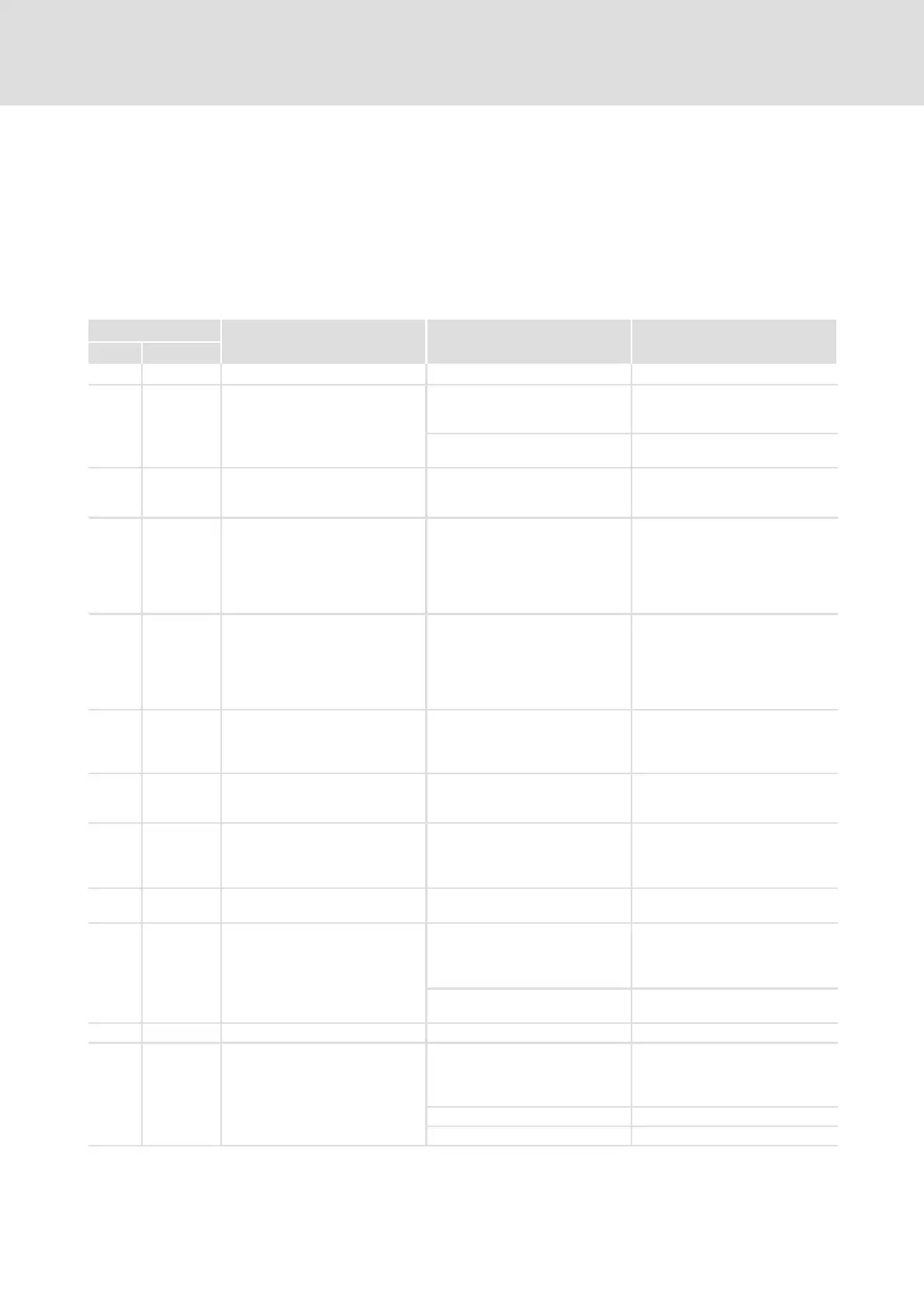

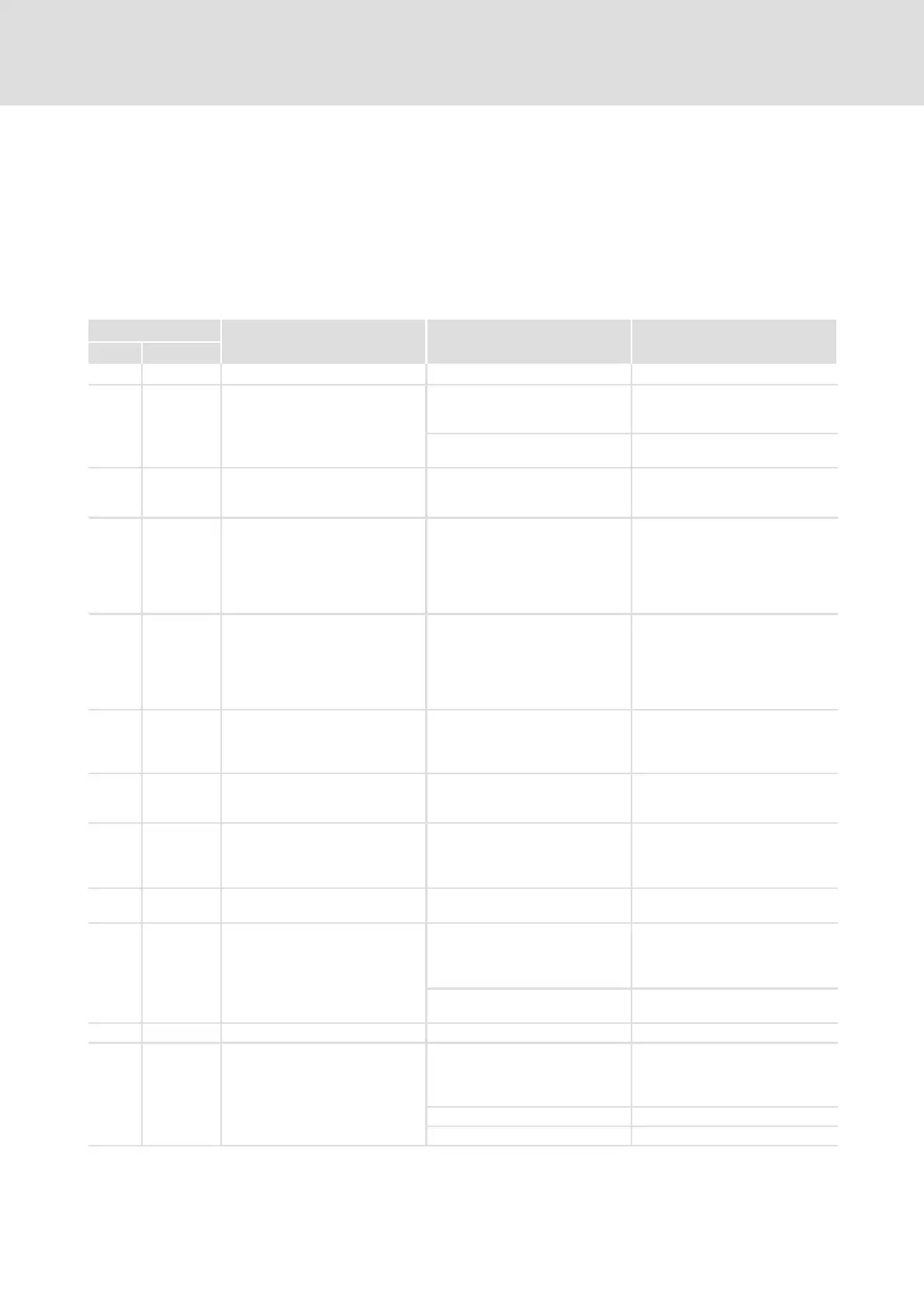

12.3.2 Causes and remedies

Tip!

When the fault messages are retrieved via the system bus (CAN) they are

displayed as a number (see column fault number ˘number" in the following

table).

Fault message

Description Cause Remedy

No. Display

−−− −−− No fault − −

0011 OC1 Short circuit of motor cable

Short circuit l Search for cause of short

circuit.

l Check motor cable.

Excessive capacitive charging

current in the motor cable.

Use motor cable which is shorter

or of lower capacitance.

0012 OC2 Motor cable earth fault One of the motor phases has

earth contact.

l Search for cause of short

circuit.

l Check motor cable.

0015 OC5 I x t overload TRIP (axis

module, fix 100 %)

Current overload of the axis

module, e.g. by:

l frequent and too long

acceleration processes

l continuous overload with

I

motor

> 1.05 x I

Nx

Check drive dimensioning.

0016 OC6 I

2

x t overload TRIP (motor, C0120) Current overload of the motor,

e.g. due to:

l frequent or too long

acceleration processes

l impermissible continuous

current

l Check drive dimensioning.

l Check setting of C0120.

x017 OC7 I x t overload warning (axis

module, C0123)

Current overload of the axis

module > C0123 (e.g. due to

frequent or too long acceleration

phases)

l Check drive dimensioning.

l Check setting of C0123.

x018 OC8 I

2

x t overload warning

(motor, C0127)

Current overload of the motor

> C0127 (e.g. due to frequent or

too long acceleration phases)

l Check drive dimensioning.

l Check setting of C0127.

1020 OU Overvoltage in DC bus Braking energy is too high.

(DC−bus voltage is higher than set

in C0173.)

l Use braking unit or

regenerative module.

l Check dimensioning of the

brake resistance.

1030 LU Undervoltage in DC bus DC−bus voltage is lower than

specified under C0174.

l Check mains voltage.

l Check power supply module.

x032 LP1 Motor phase failure

A current−carrying motor phase

has failed.

l Check motor.

l Check motor cable.

l Switch off monitoring

(C0597 = 3).

The current limit value is set too

low.

l Set higher current limit value

via C0599.

x041 AP1 Internal fault Contact Lenze.

0050 OH Heatsink temperature > +90 °C

Ambient temperature

T

u

> +40 °C or > +50 °C

l Allow module to cool and

ensure better ventilation.

l Check ambient temperature in

the control cabinet.

Heatsink is very dirty. Clean heatsink.

Wrong mounting position Change mounting position.

x: 0 = TRIP, 1 = Message, 2 = Warning, 3 = FAIL−QSP

Loading...

Loading...