Electrical installation

Power terminals

5

62

EDBCSXA064 EN 3.2

ƒ All power connections are plug connections and coded. The ECSZA000X0B plug

connector set must be ordered separately.

ƒ Installation of the cables to EN 60204−1.

ƒ The cables used must comply with the approvals required at the site of use (e.g. VDE,

UL, etc.).

Note!

ECSDA... axis modules:

For a better electromagnetic compatibility (EMC), connect the functional earth

conductor to the ECSDA... axis module ( 54).

This is not required for the ECSEA... (standard installation) and ECSCA... (cold

plate) axis modules!

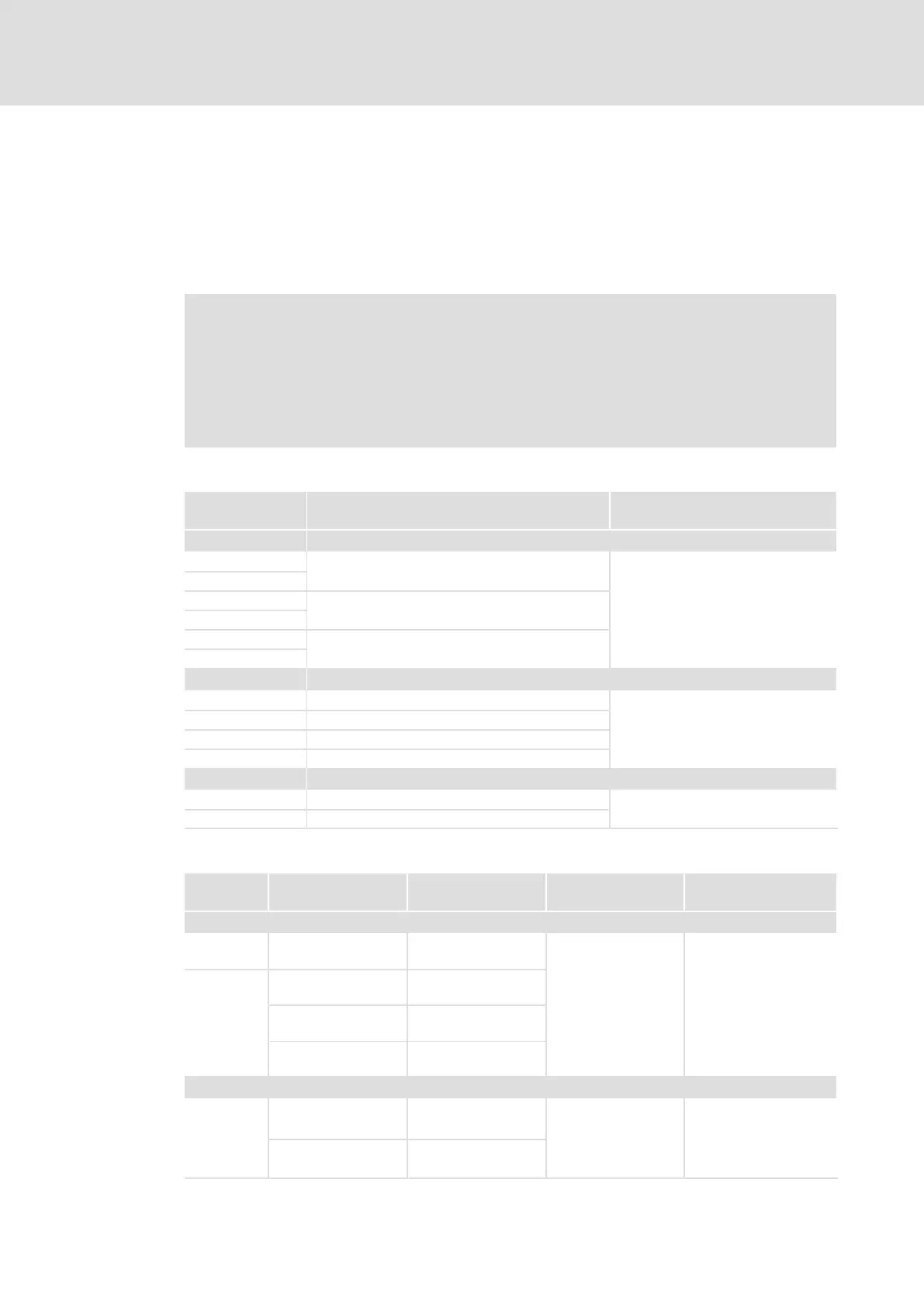

Assignment of the plug connectors

Plug

connector/terminal

Function Electrical data

X23 DC−bus voltage connection

X23/+UG

Positive DC−bus voltage

Dependent on application and type

0 ... 770 V

2 ... 24.5 A ( 42)

X23/+UG

X23/−UG

Negative DC−bus voltage

X23/−UG

X23/PE

Earth connection

X23/PE

X24 Motor connection

X24/U Motor phase U

Dependent on application and type

0 ... 480 V

1.6 ... 20 A ( 42)

X24/V

Motor phase V

X24/W Motor phase W

X24/PE Earth connection

X25 Motor holding brake connection

X25/BD1 Brake connection +

23 ... 30 V DC,

max. 1.5 A

X25/BD2 Brake connection −

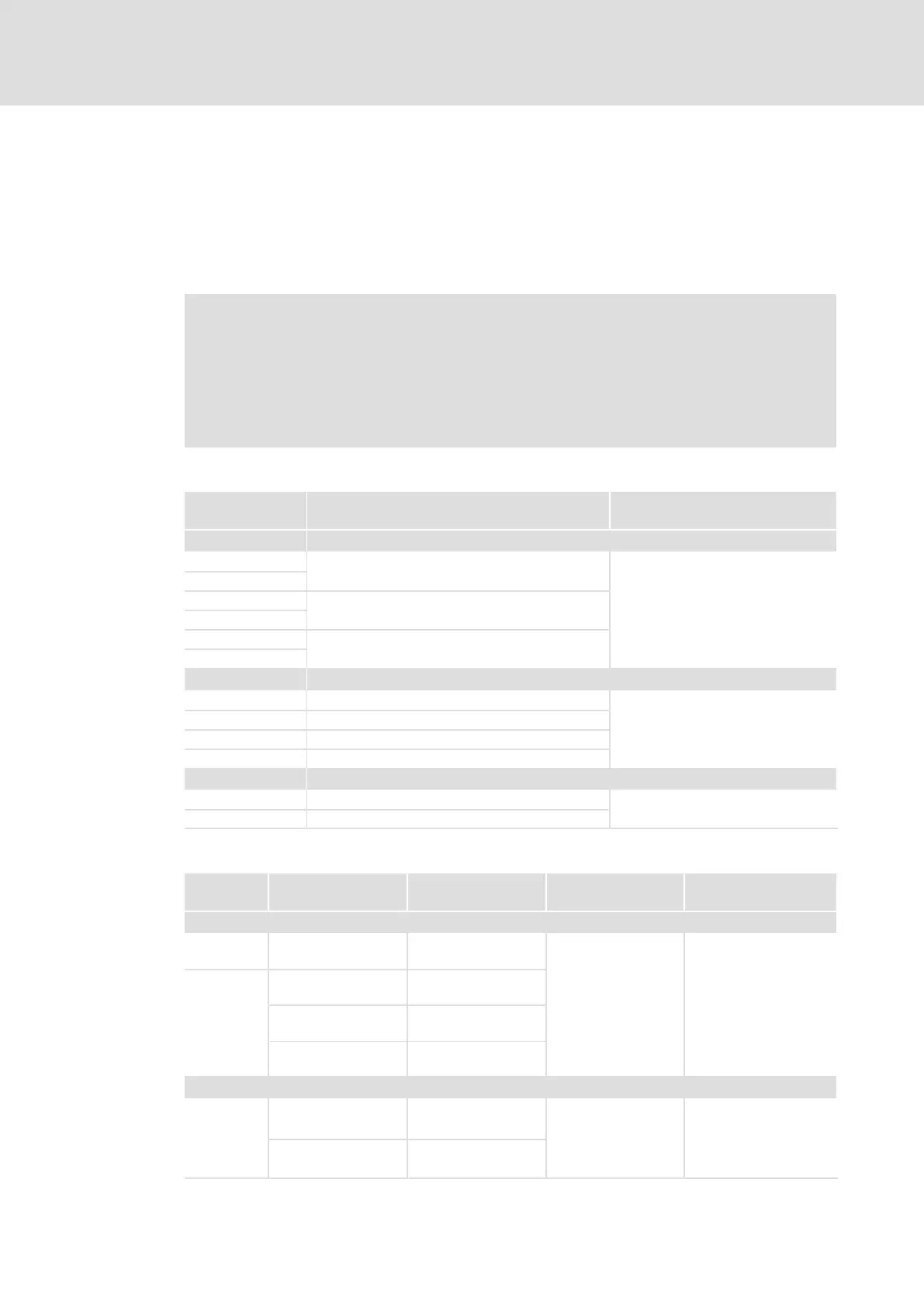

Cable cross−sections and screw−tightening torques

Cable type Wire end ferrule Possible cable

cross−sections

Tightening torque Stripping length

Plug connectors X23 and X24

Rigid ˘

0.2 ... 10 mm

2

(AWG 24 ... 8)

1.2 ... 1.5 Nm

(10.6 ... 13.3 lb−in)

5 mm for screw

connections

10 mm for spring

connections

Flexible

Without wire end

ferrule

0.2 ... 10 mm

2

(AWG 24 ... 8)

Insulated with wire

end ferrule

0.25 ... 6 mm

2

(AWG 22 ... 10)

Insulated with wire

end ferrule

0.25 ... 4 mm

2

(AWG 22 ... 12)

Plug connector X25

Flexible

Insulated with wire

end ferrule

0.25 ... 2.5 mm

2

(AWG 22 ... 12)

0.5 ... 0.8 Nm

(4.4 ... 7.1 lb−in)

5 mm for screw

connections

10 mm for spring

connections

Without wire end

ferrule

0.2 ... 2.5 mm

2

(AWG 24 ... 12)

Loading...

Loading...