7

Controller system settings

7-8

8. Initialize

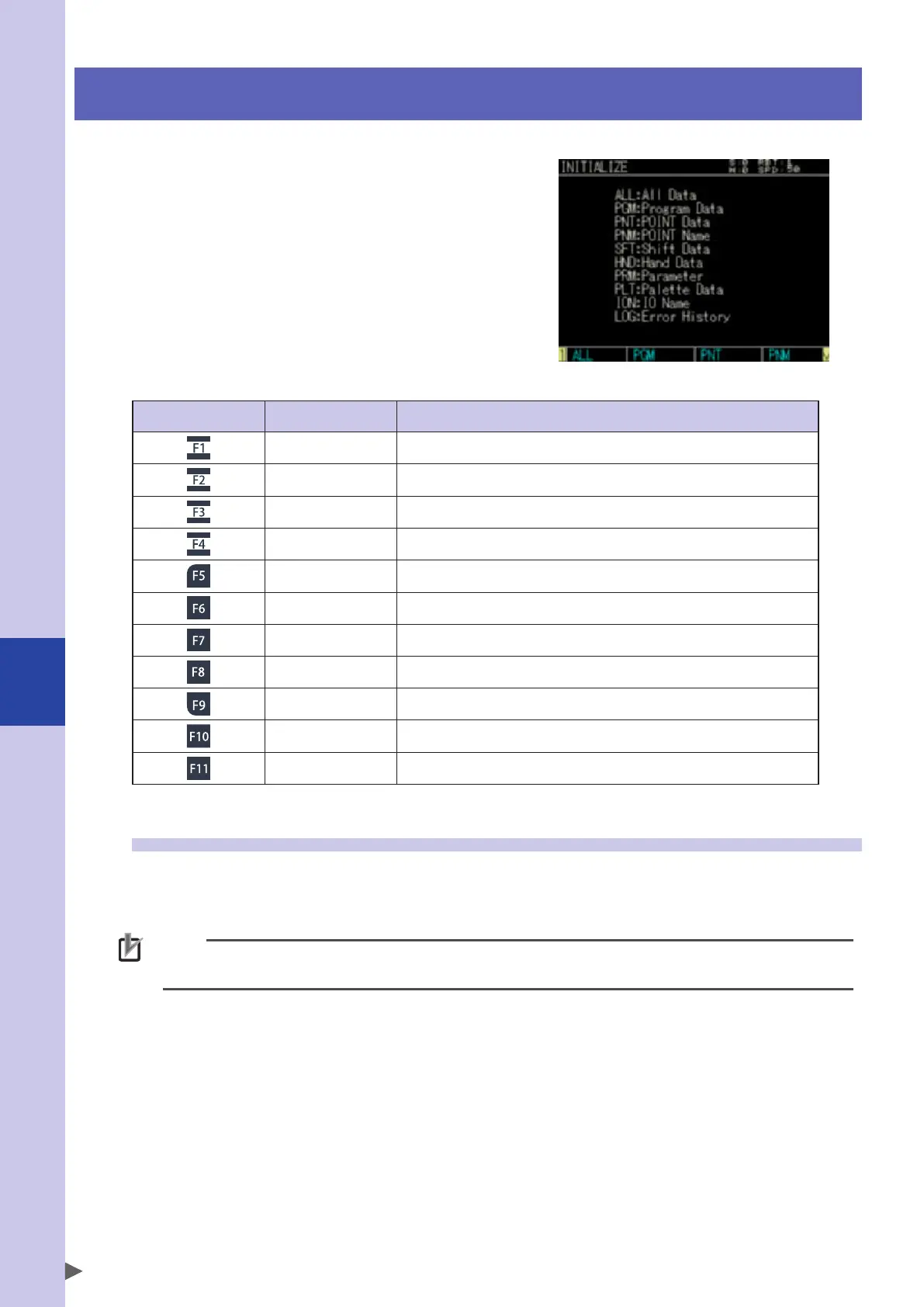

When selecting [System] - [Initialize] from the

initial screen, the "Initialize" screen will appear.

On this screen, you can initialize the data managed

by the controller. Use the F1 key (ALL DATA) to F11

(CLOCK) to select the item to initialize.

■ "INITIALIZE" screen

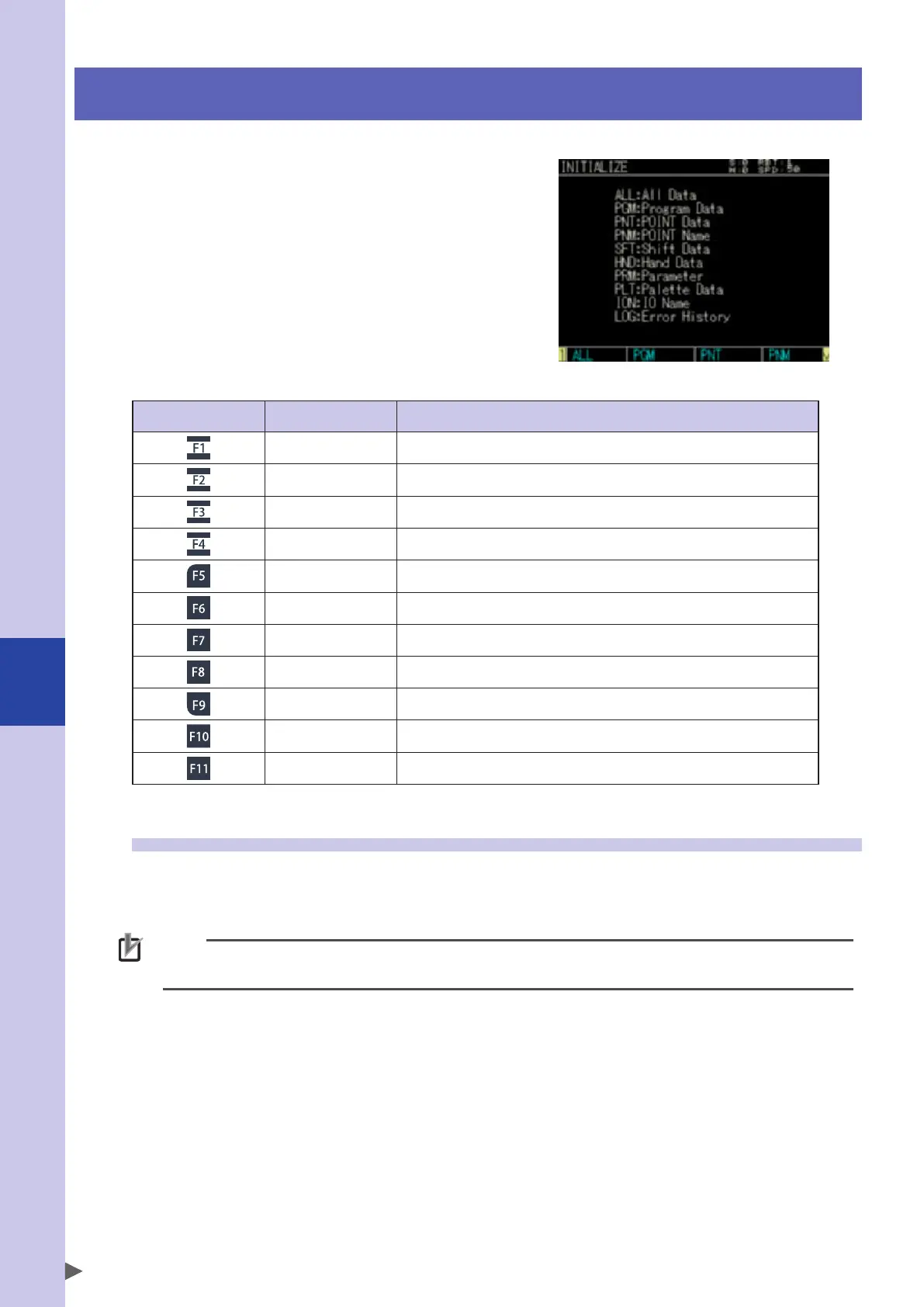

Valid keys and submenu descriptions on the "INITIALIZE" screen are shown below.

Valid keys Menu Function

ALL Initializes all data.

PGM Deletes the program data.

PNT Deletes the point data.

PNM Deletes the point name data.

SFT Deletes the shift coordinate data.

HND Deletes the hand definition data.

PRM Initializes the parameter data.

PLT Deletes the pallet definition data.

ION Deletes the I/O name data.

LOG Deletes the alarm history data.

CLOCK Sets the clock.

8.1 Initializing the data

Programs, point data, point names, shift coordinates, hand definitions, parameters, pallet definitions, IO

names, and alarm history data are initialized or deleted.

Before executing the initialization process, carefully check that the currently input data is unnecessary.

NOTE

• Once the memory is initialized, the external data needs to be input to restore the data.

• If the memory is corrupted for some reason, the memory needs to be initialized.

Loading...

Loading...