retaining

the coolant for

íurther

use if

antifreeze has been

added.

1 Remove the spaÍk

plug

leads,

spark

plugs

and

dicf rihr rfnr nrn

2

Remove the

top radiator

hose. rocker lubrication

pipe

and the

Ían

belt.

3 Disconnect from the

cylinder head the lower

radiatoÍ hose

and the

heater

connection.

4 Remove the

petrol

Íeed

and the distributor vacuum

lines,

disconnect the accelerator

and choke controls

at the carburetter and

remove

the

air cleaner and the

rocKer cover.

5 Remove

the carburetter and inlet

pipe

with

the

difÍuser.

6 Uníasten the exhaust flange,

the

front

mufÍler

attachment

collar and the sliding lug

of

the

generatoÍ

to cylinder head.

7

Disconnect

the electrical leads

to the magnetic

Ían.

8 Refer to FIG

1:6

and remove

the cylinder

-head

attaching

bolts

Nos.

8 and 12.

9

Fit

cylinder head

guides,

8.01 15,

into

the holes

vacated

by bolts I and

12

and

screw in

completely.

The

guides

have a knurled end fitting

with a leÍthand

thread which should

unscrew as soon as the

guide

comes

level with

the top of the rocker

gear

bearing.

10 Remove

the

remaining

cylinder head bolts

and

rocker

attaching nuts and withdraw

the rocker assembly

and

pushrods,

cylinder head and

gasket.

11 Lock

the cylinder liners

by

means

of the locking

screws

8.01 04D as shown in FIG 1 :7. lf

the

soecial

screws

are not available

a

large

washer may be used

in

conjunction

with a spacer

and a cylinder head bolt.

BeÍore replacing

the cylinder head

careÍully

clean

the

joint

faces

on the cylinder

block and

the cylinder

head.

Ensure

that both faces

are true. The

maximum

out of

true

tolerance is .05mm.

Should this tolerance

be

exceeded

the cylinder

head

joint

face may be surfaced

providing

the

minimum

overall depth

of the cylinder

head is

not

reduced below

91

.5mm;|.15.

The

cylinder block.loint

face

should never

be machined,

The

cylinder head

gasket

is

made

oÍ an asbestos

sheet

set between two sheets

oí

galvanized

iron. As from

September

1960,

the setling

width at both

ends oÍ

the

.ioint

has

been

reduced from

3 to

2mm. In

addition,

the

setting

at

the

rear end has been interrupted,

in order

to

improve

the

elasticity of the

gasket.

The

corners oÍ

the

gasket

are cut

in

order to

permit

measuring with

a set

oÍ

shims the thickness

of the

gasket

under load.

Thickness

of the

gasket

under

'1

500

kg

load,

equal

to

normal

torque

loading

oí the

cylinder head, should

be

1.5mm

+.1.

BeÍore

placing

the

gasket

on the

cylinder block, coat

the

gasket

on both sides with light

grease

or engine

oil.

Replace the

cylinder head in

the

following

manneÍ:

1

Remove

the cylinder liner locking

screws and

place

the

cylinder

head

gasket

in

position

on the

cylinder

block.

The

cylinder head

gasket

should be

fitted

wirh

the

marking DESSUS

Íacing

upwards. Make

sure that

the crankshaft is not rotated

while

the liners are

not locked

in

position

with the retaining

screws.

2 Place

the

cylinder head in

position

on the cylinder

block

(see

FIG 1 :8)

and

Íit

Nos. 3 and 7 retaining

bolts

(see

FIG 1:6).

Assemble the

pushrods

and rocker

assembly

and fit the remaining

cylinder head

bolts and

P404

)

"r/

l(

I

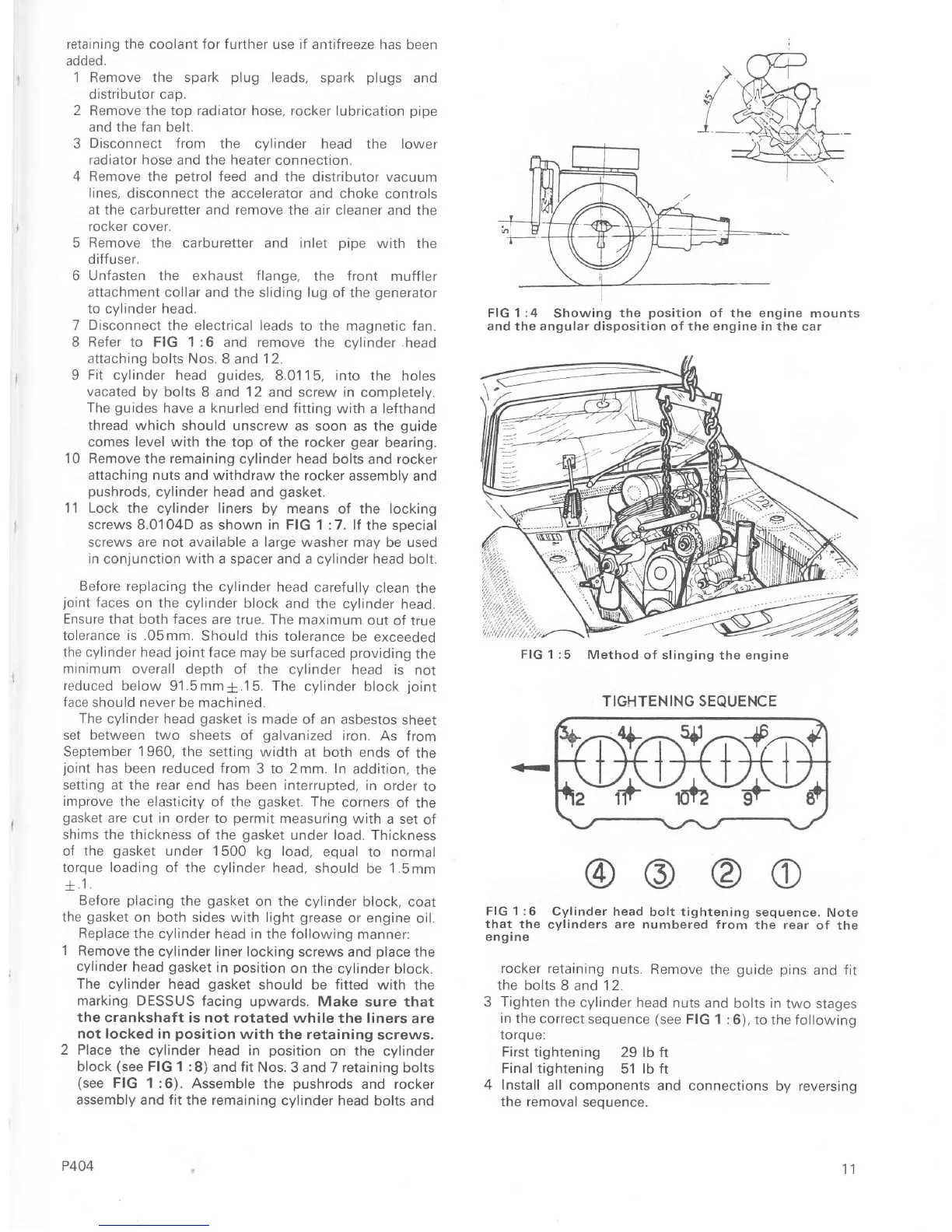

FIG

1 :4

Showing

the

position

of the engine

mounts

and the angular disposition oÍ the engine in the

car

FIG 1 :5

Method of slinging

the engine

@o @

e

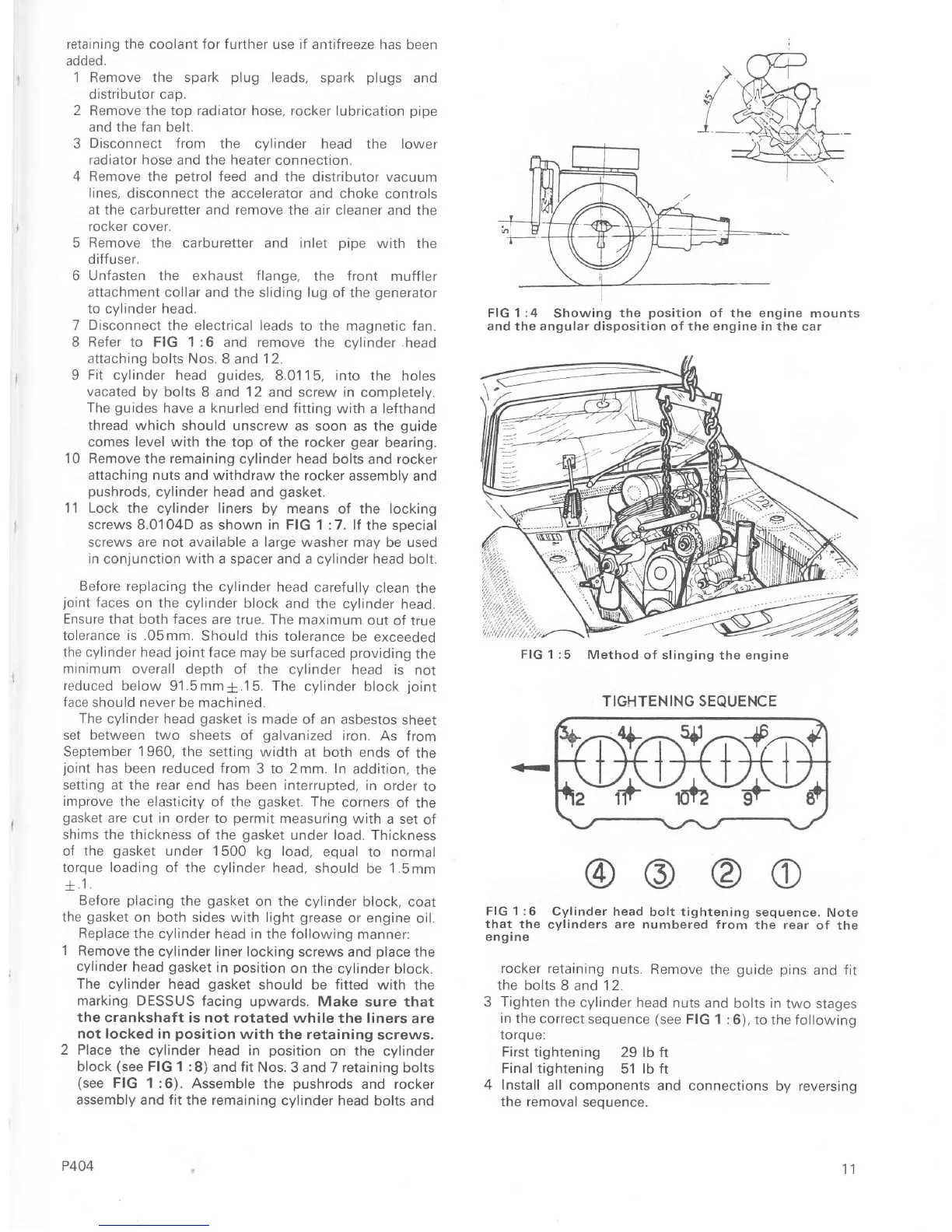

FIG

1 :6

Cylinder head

bolt tightening

sequence.

Note

that the

cylinders

are

numbered Írom

the

rear

of

the

engrne

rocker

Íetaining

nuts.

Remove the

guide

pins

and

fit

the

bolts 8

and

12.

3

Tighten

the

cylinder head nuts

and

bolts

in

two stages

in

the correct

sequence

(see

FIG 1 :6),

to the Íollowrng

toroue:

First

tightening 29 lb ft

Final

tightening

51

lb ft

4 Install

all components and

connections

by reversing

the removal

sequence.

11

TIGHTENING SEQUENCE

í+:''o+i

Loading...

Loading...