\hb

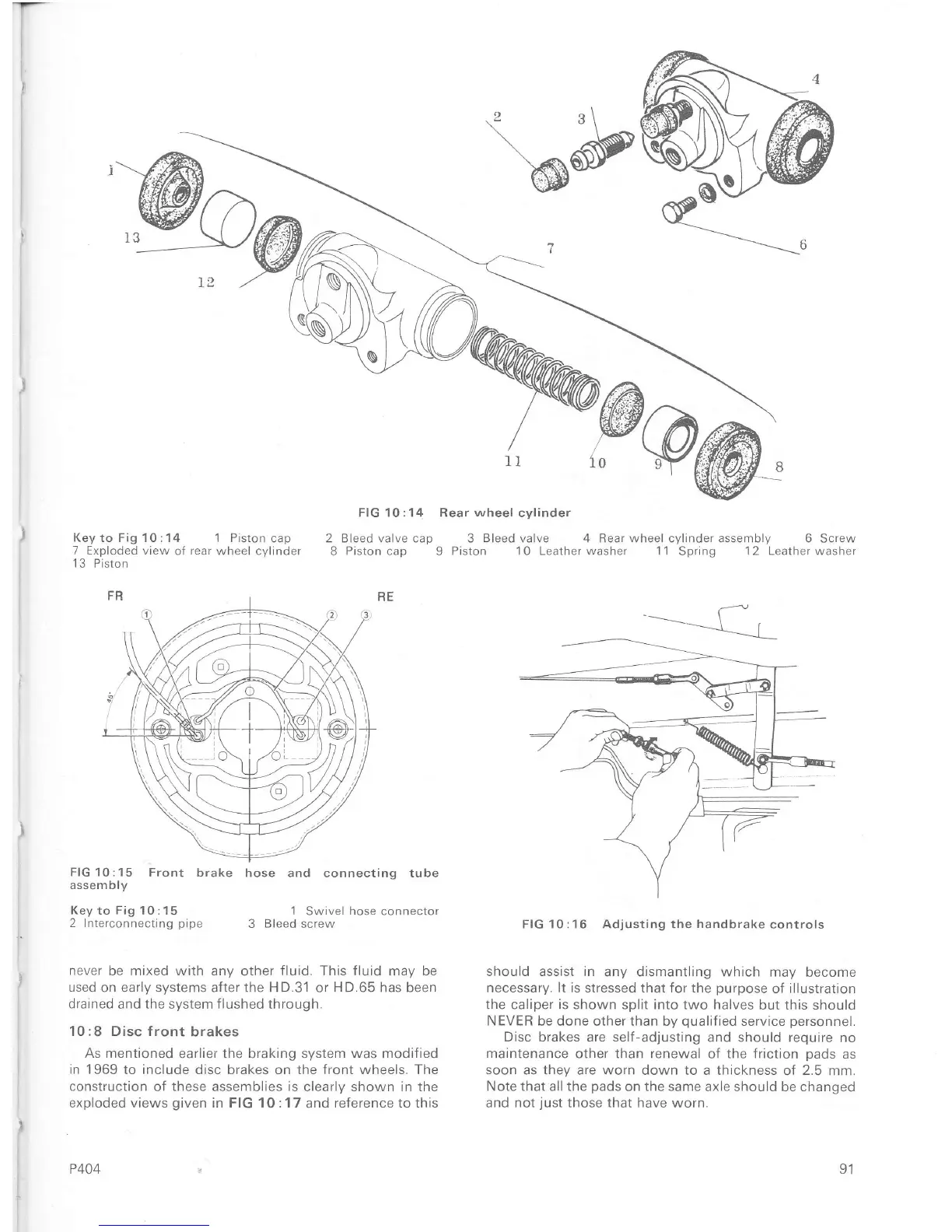

FIG 10:14 Rear

wheel

cylinder

2 Bleed valve cap 3

Bleed

valve 4 Rear wheel cylinder assembly 6 Screw

8

Piston cap

9

Piston 1

0

Leather washer 1'1

Spring

1 2 Leather washer

J

r^r

)

Key to Fig 1 0 :1 4 1 Prston

cap

7 Exploded view

oÍ

rear

wheel cylinder

1

3 Piston

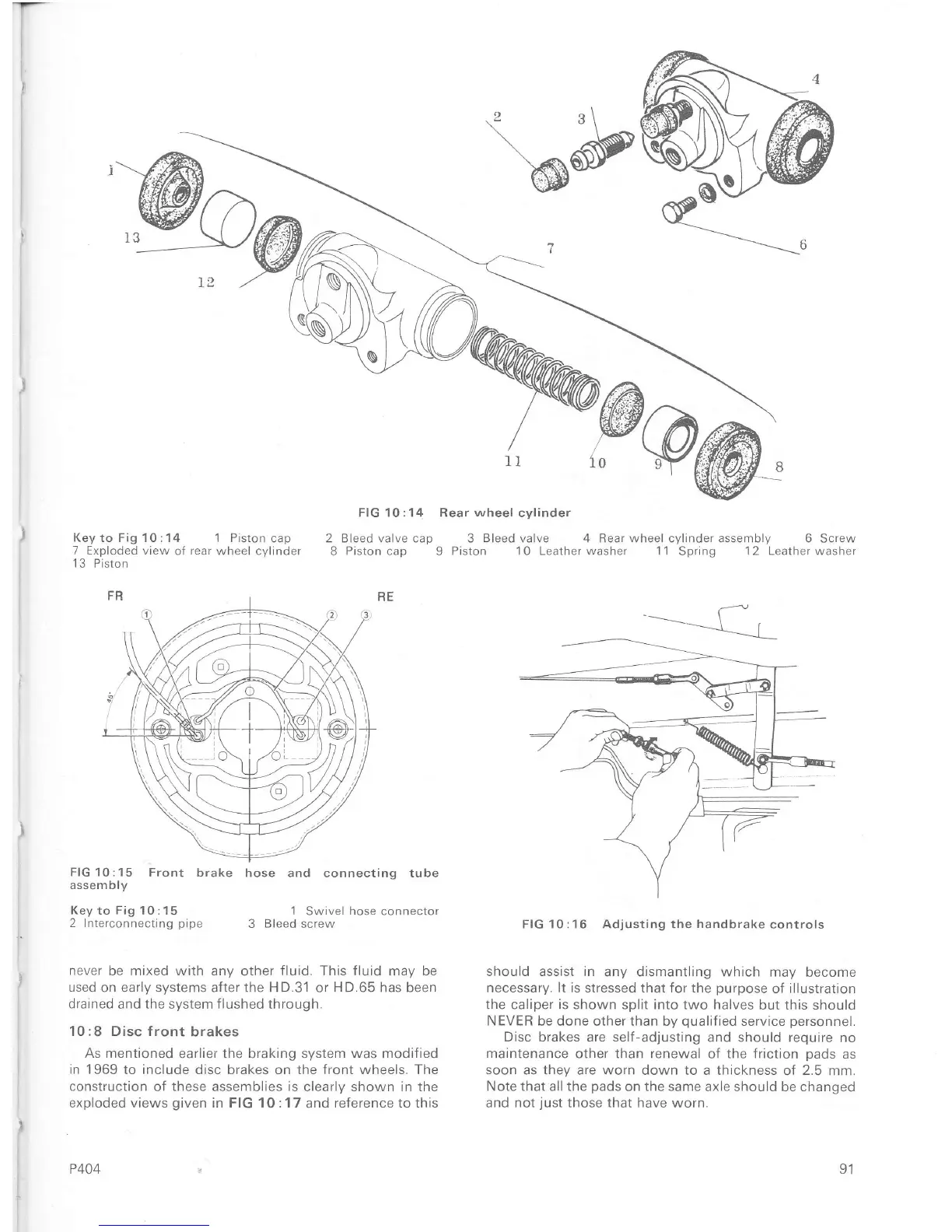

FlG10;15

Front brake

assembly

Keyto Fig

10:15

2 Interconnecting

pipe

hose and connecting tube

1

Swivel

hose

connector

3

Bleed

screw

FIG 10:16 Adjusting the

handbrake

controls

should assist in

any dismantling which may

become

necessary. lt is stressed that Íor the

purpose

of illustration

the caliper

is

shown split into two halves

but this should

NEVER be done other than

by

quaiiÍied

service

personnel.

Disc brakes are self-adjusting

and should require

no

maintenance other than renewal of the friction

pads

as

soon

as

they

are

worn

down to a thickness

of

2.5

mm.

Note that all the

pads

on

the same

axle should be changed

and

not

iust

those that have

worn.

never

be mixed with any other

fluid.

This fluid may be

used

on early systems aÍter the HD.31 or HD.65 has been

drained

and

the

system

flushed

through.

10 :8 Disc front

brakes

As mentioned

earlier the braking

system was

modified

in 1969

to include disc brakes on the front wheels. The

construction

of

these

assemblies

is

clearly shown in the

exploded views

given

in FIG 10:17

and

reference to this

P404 91

Loading...

Loading...