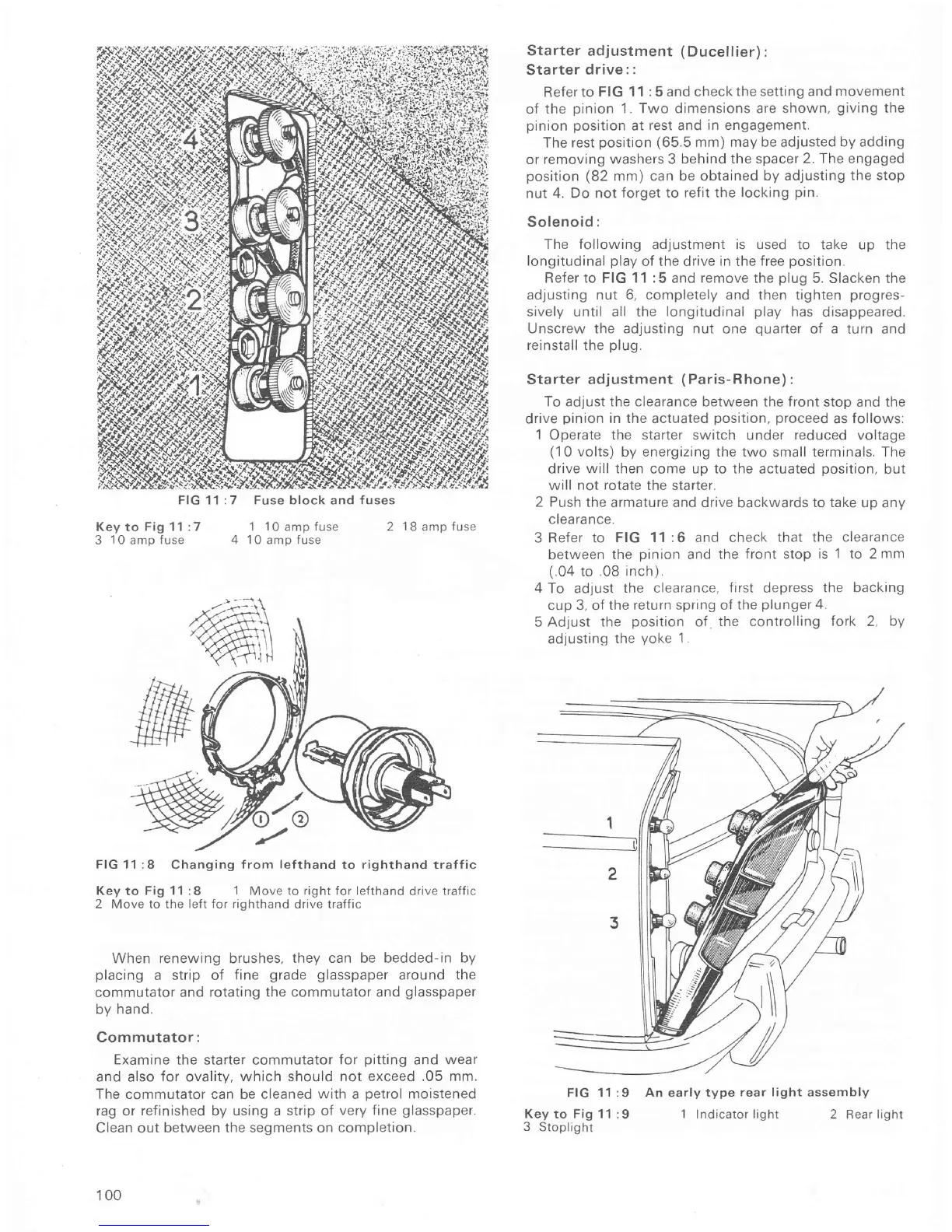

FIG 11:7

Key

to

Fig 11 :7

3

10ampÍuse 4

Fuse block and fuses

1

10

amp Íuse 2

18

amp

fuse

1

0

amp Íuse

Starter adjustment

(Ducellier)

:

Sta

rter d

rive : :

ReÍer to

FIG 1 1

:

5 and check

the setting and movement

of

the

pinion

1. Two dimensions are shown,

giving

the

pinion position

at rest and

in

engagement.

The

rest

posit;on (65.5

mm) may be adjusted by adding

or removing

washers 3 behind the

spacer 2. The engaged

position (82

mm) can be obtained

by adjusting

the stop

nut 4. Do not

forget to reÍit the

locking

pin.

Solenoid:

The following adjustment is

used

to

take up the

longitudinal

play

of the drive

in

the

Íree

position.

Refer to FIG 11 :5

and

remove

the

plug

5.

Slacken the

adlusting nut 6, completely and then tighten

progres-

sively

until

all

the

longitudinal

play

has disappeared.

Unscrew the ad.justing nut

one

quarter

of

a

turn and

reinstall

the

plug.

Starter adjustment

(

Paris-Rhone)

:

To adjust the clearance between the front

stop and the

drive

pinion

in the

actuated

position,

proceed

as

follows:

l

Operate

the

starter switch under reduced voltage

(10

volts) by energizing the two small terminals, The

drive

will then

come up

to the

actuated

position,

but

will not

rotate

the starter.

2 Push

the armalure and

drive backwards

to take

up any

clearance.

3 ReÍer to

FIG 11:6 and check that

the clearance

between

the

pinron

and

the front stop

is 1 to

2

mm

(.04

to

.08 inch)

4

To adjust

the clearance,

first

depress

the backing

cup 3, oÍ the

return

spring oÍ

the

plunger

4.

5 Adjust

the

position

of

the controlling

fork

2,

by

adjusting

the

yoke

'1

.

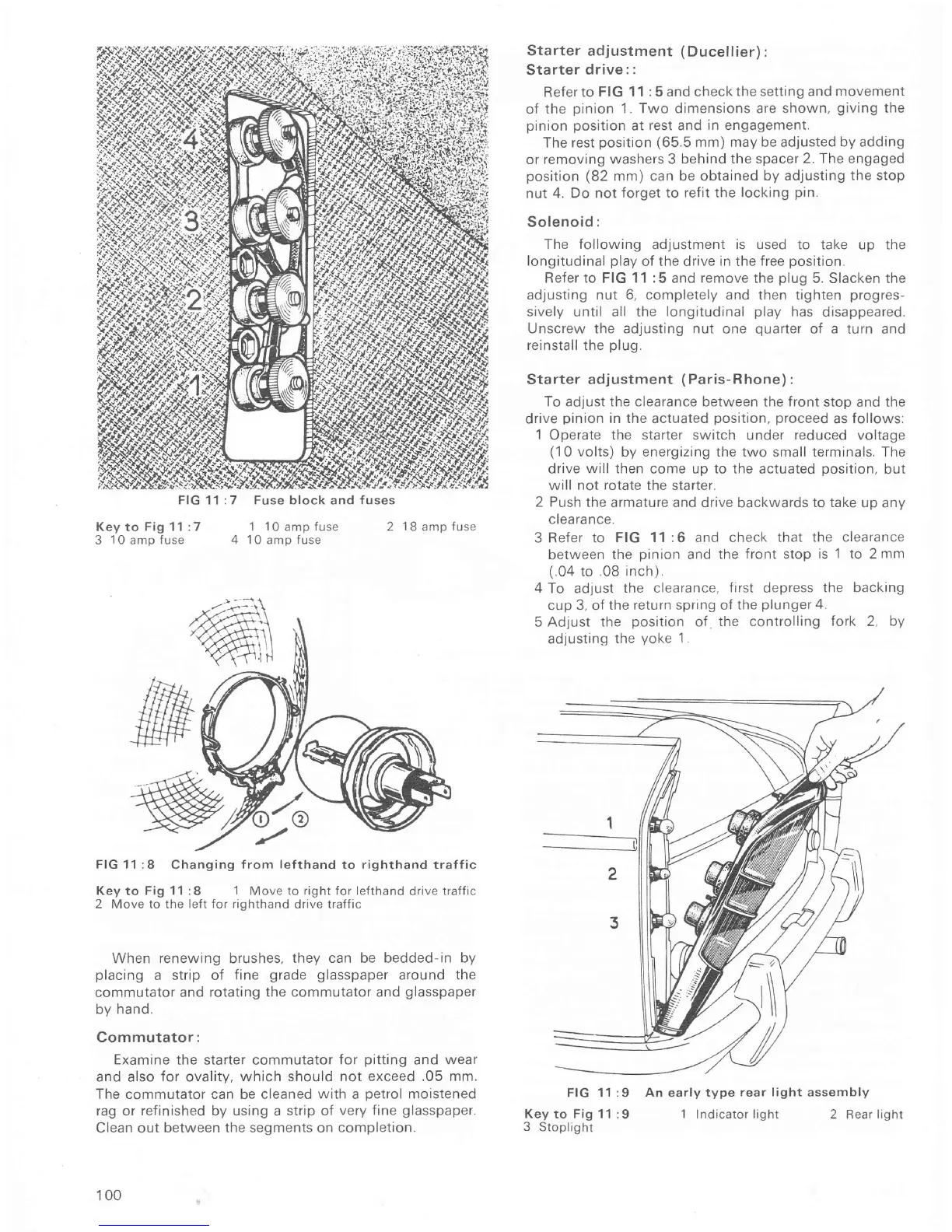

FIG

11 :9 An

early

type

rear light assembly

Key to Fig 11 :9 1 Indicator light 2

Rear

light

3

Stoplight

FIG 11 :8 Changing from

leÍthand

to righthand traffic

Key

to

Fig 11 :8 1

Move

to right for lefthand

drive

traffic

2 Move to the

leÍt for righthand

drive trafÍic

When renewrng brushes,

they can be bedded-in by

placing

a strip of

Íine

grade glasspaper

around the

commutator and

rotating the commutator and

glasspaper

bv

hand.

Commutator:

Examine

the starter commutator

Íor

pitting

and wear

and also Íor ovality,

which

should

not exceed

.05

mm.

The commutator can be cleaned

with

a

petrol

moistened

rag or refinished by using

a

strip of

very fine

glasspaper.

Clean out between the segments on

completion.

100

Loading...

Loading...