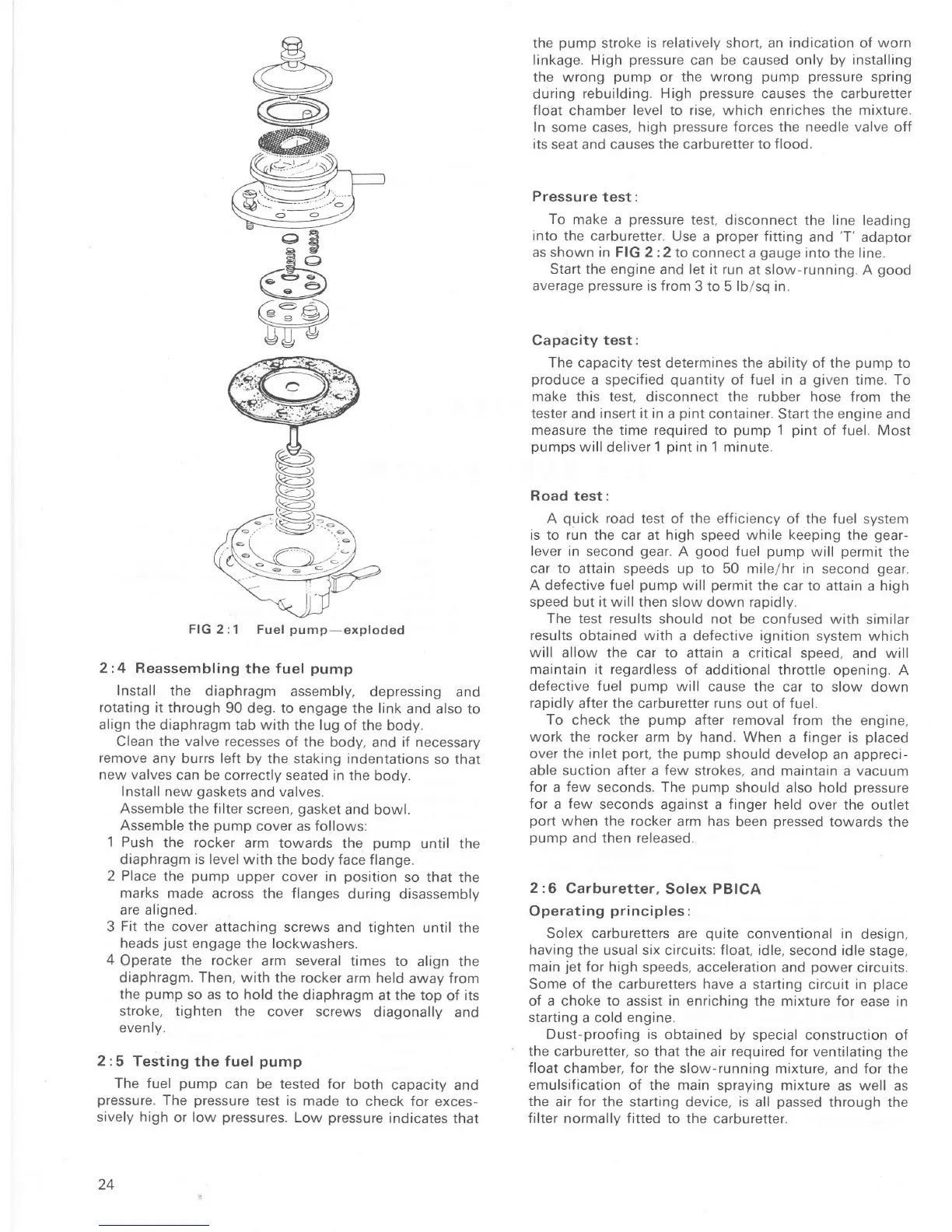

FIG

2:1 Fuel

pump-exploded

2 :4 Reassembling

the

f

uel

pump

Install

the diaphragm

assembly,

depressing and

rotating it through

90 deg. to engage

the link

and also to

align the diaphragm

tab with the lug

of the body.

Clean the

valve

recesses

oÍ

the

body,

and

if necessary

remove

any burrs left

by the staking indentations

so that

new valves can

be correctly seated in

the body.

Install

new

gaskets

and

valves.

Assemble the filter

screen,

gasket

and bowl.

Assemble the

pump

cover

as

follows:

1 Push

the rocker

arm towards

the

pump

until

the

diaphragm

is level

with the body

face flange.

2

Place

the

pump

upper cover in

position

so that

the

marks made

acÍoss the

flanges

during disassembly

are aligned.

3

Fit the cover

attaching screws

and tighten

until the

heads

just

engage

the

lockwashers,

4

Operate the rocker

arm several times

to align the

diaphragm. Then, with

the

rocker

arm

held

away from

the

pump

so as to hold the

diaphragm

at

the top

of

its

stroke, tighten

the cover scÍews

diagonally

and

evenry.

2 :5 Testing

the fuel

pump

Ïhe fuel

pump

can

be

tested for

both

capacity

and

pressure.

The

pressure

test

is

made

to check for exces-

sively high

or

low

pressures.

Low

pressure

indicates

that

z4

the

pump

stroke

is relatively short, an indication oÍ worn

linkage.

High

pressure

can

be

caused only by installing

the wrong

pump

or the

wrong

pump pressure

spring

during

rebuilding. High

pressure

causes the carburetter

Íloat

chamber

level to rise, which enriches the mixture.

In some cases. high

pressure

forces the needle valve

off

its

seat and causes the

carburetter to flood.

Pressure

test:

To

make a

pressure

test, disconnect the

line leading

into the

carburetter. Use

a

proper

Íitting

and

'T'

adaptor

as

shown

in FIG 2 :2 to

connect a

gauge

into

the

line.

Start the engine

and

let

it run

at slow-running. A

good

average

pressure

is from

3 to 5

lb/sq in.

Capacity test:

The capacity test

determines

the

ability oÍ the

pump

to

produce

a specified

quantity

of

fuel in a

given

time.

To

make this test, disconnect the rubber hose from

the

tester and insert it in a

pint

container. Start the engine and

measure

the time

required

to

pump

1

pint

of fuel. Most

pumps

will

deliver

1

pint

in 1 minute.

Road

test:

A

quick

road

test oÍ

the

eÍÍiciency oÍ the fuel

system

is to run

the

car

at

high

speed

while keeping

the

gear-

lever in

second

gear.

A

good

fuel

pump

will

permit

the

car to attain speeds up to 50 mile/hr in

second

gear.

A defective fuel

pump

will

permit

the car to attain

a

high

speed

but

it

will then slow down rapidly.

The

test results should

not be confused with similar

results

obtained

with

a deÍective ignition

system which

will

allow the car to attain

a critical

speed,

and will

maintain it regardless oÍ

additional throttle

opening. A

defective fuel

pump

will cause the

car to slow down

rapidly

after

the carburetter runs

out oÍ

Íuel.

To

check the

pump

aÍter removal from

the engine,

work the rocker

arm by hand. When

a

finger

is

placed

oveÍ the inlet

port,

the

pump

should develop

an appreci-

able suction after a few

strokes, and maintain

a

vacuum

for a few

seconds. The

pump

should

also hold

pressure

íor a few

seconds against a Íinger held

over the outlet

port

when

the

rocker

arm has

been

pressed

towards the

pump

and then released.

2:6

Carburetter,

Solex PBICA

Operating

principles:

Solex carburetters are

quite

conventional in

design,

having

the usual six circuits: float, idle, second

idle stage,

main

jet

for high

speeds, acceleration and

power

circuits.

Some of the carburetters

have

a starting

circuit

in

place

of a choke to assist in enriching

the

mixture

for ease in

starting

a cold

engine.

Dust-proofing is obtained

by special construction

of

the carburetter,

so that the

air

required Íor ventilating

the

Íloat

chamber, Íor the slow-running

mixture,

and

for

the

emulsification

oÍ the main spraying mixture

as well as

the

air

Íor

the starting device, is

all

passed

through the

Íilter

normally fitted to the

carburetter.

Loading...

Loading...