Connecting rod bearings:

The steel

and

lead

bearing shells

are

interchangeable

in order to

peÍmit

trueing up the

crankpins.

Four

types

oÍ

bearings

are available, identiÍied

by their thickness

measured

at the centre oÍ the shells.

Original thickness

1 st

oversize

2nd

oversize

3rd oversize

1 .81

9 to

1 .825

mm

1 .969 to 1 .975 mm

2.069 to

2.075 mm

2.219 to 2.225mm

Gudgeon

pins:

The

gudgeon pins

are

fitted

off centre

in the

pistons

and are

held in

place

with

circlips.

The

gudgeon pins

and

pistons

are mated duÍing manufacture and

must

always

be

kept together

to

pÍevent

an overtight

Íit which

could

subsequently cause engine damage.

In the case

of a

'liners

and

pistons'

exchange,

remove

the

gudgeon

pins

from the new

pistons

which are

paired

with the cylinder

liners. Lubricate the

gudgeon pins

and

push

them

by

hand into the

pistons

and connecting

rod

small-ends.

Refit the circlios.

To reÍit the

pistons

and

connecting rod assemblies

to the engine

proceed

as

follows:

1 lf the

old

pistons

are to be used, decarbonize

the

piston

crowns and

the ring

grooves.

2

Check

the

piston

ring

gaps.

Locate the

piston

ring in

the unworn

portion

of

the cylinder liner and check the

ring

gaps

which should be

.4 mm

for both compression

and oil scraper rings.

3 Assemble the

piston

to

the connecting

rod, so that

when assembled in the

engine,

the

oil

squiÍt hole in

the big-end

(see

FIG 1 :24), is

to the side opposite the

camshaft and the

AV

marking and arrow stamped on

the

piston

crown

point

to the front

of

the

engine.

4 Fit

the compression

rings

to the

pistons

with the

reference marks facing

upwards and the

chrome

faced

ring in the top

groove.

5

With

the

ring

gaps

spaced at 120 deg., f it the

piston

and connecting rods to

their

respective

cylinder bores

from which

they were

removed.

Assemble the big-

end bearing

shells and caps, ensuring that the

mating

marks

between the caps and rods are corÍectly Íelated

and that each

assembly

is in the

bore

from which it

was removed

on dismantling. Fit new big-end bolts

and lockwashers

and

tighten the

bolts

to

a

torque

oÍ

30.7 ro 34.3 lb fr.

1 :12 Removing the

crankshaft

and main

bearings

With

the engine removed from

the car

(see

Section

1 :3), remove the

transmission

(see

Section

6), the oil

sump, the clutch and flywheel

(see

Section

1 :9),

and

the timing

chain and sprockets

(see

Section

1 :6).

Remove the

sparking

plugs

and turn the engine upside

down.

First

check the cÍankshaft end Íloat with

a dial

gauge,

levering

the óhaÍt endwise. The

correct clearance should

be

.08

to

.2mm.

Release the

connecting rods and replace the

caps

on

their respective rods.

Remove the main bearing bolts and

remove

the bearing caps.

P404

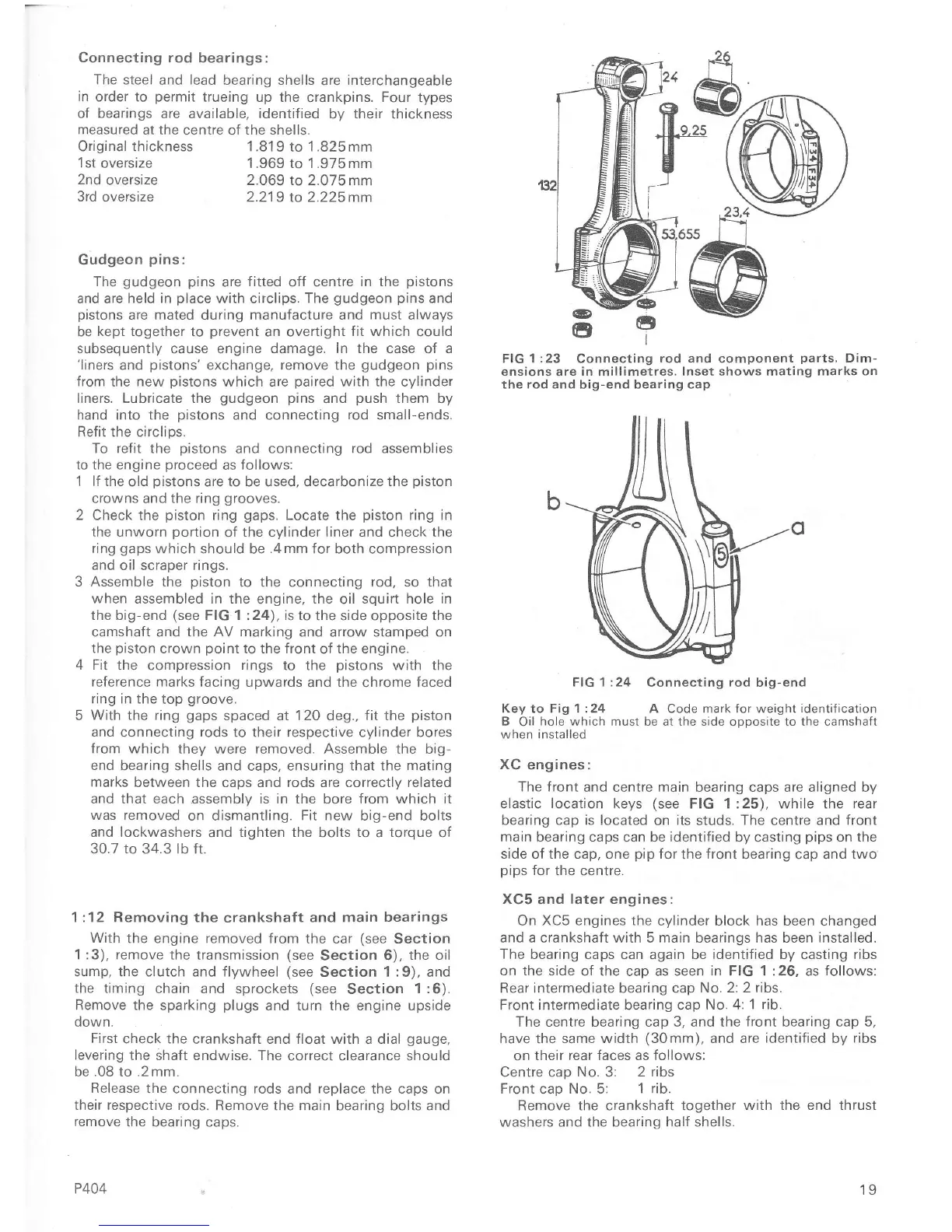

FIG 1:23 Connecting

rod

and component

parts.

Dim-

ensions are in

millimetres.

lnset shows mating marks

on

the rod and

big-end bearing

cap

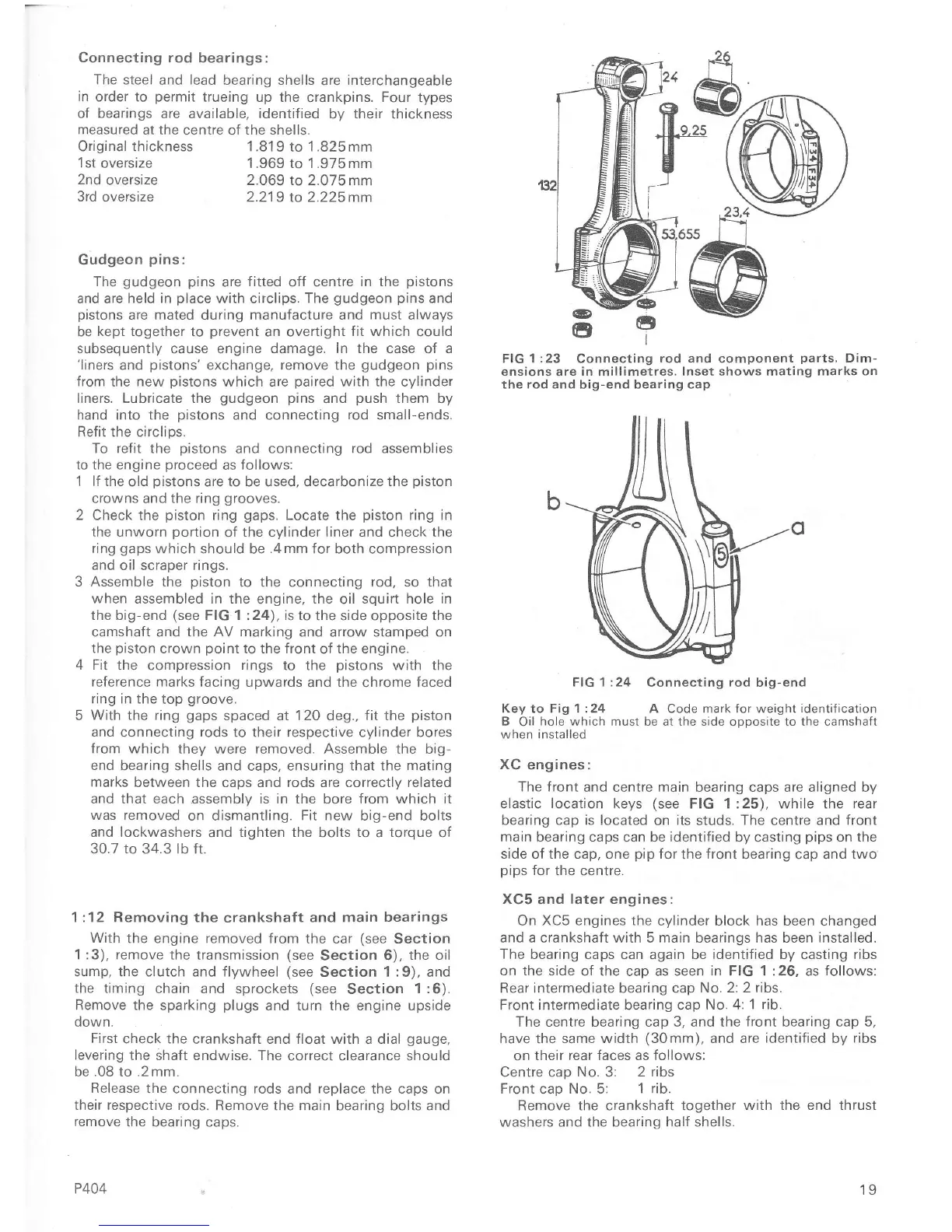

FIG 1 :24

Connecting

rod

big-end

Key to Fig 1 :24 A Code mark Íor weight

identification

B

Oil

hole which must be at the side ooposite to the camshaÍt

when installed

XC

engines:

The front

and centre

main

bearing caps are aligned by

elastic

location

keys

(see

FIG 1:25), while the rear

bearing cap is located

on

its

studs.

The

centre and

front

main bearing caps can be identified by casting

pips

on the

side of the cap, one

pip

for

the

front

bearing cap and

two

pips

for

the centre.

XC5

and

later engines:

On

XC5

engines

the

cylinder block has been changed

and a crankshaft with 5 main bearings has been

installed.

The bearing caps

can

again

be

identified by

casting

ribs

on the side

of the cap as seen

in FIG 1

:26, as

follows:

Rear intermediate bearing cap

No. 2:2 ribs.

Front

intermediate

bearing cap

No. 4'. 1

rib.

The centre bearing cap 3, and the

front

bearing cap 5,

have

the

same width

(30mm),

and are

identified

by

ribs

on

their rear faces as follows:

Centre cap

No.

3:

2 ribs

FÍont

cao

No. 5: 1

rib.

Remove the crankshaft together

with the end thrust

washers and the bearing half shells.

É

I

(D

a

19

Loading...

Loading...