<gï1)

)

c

{fft

ob

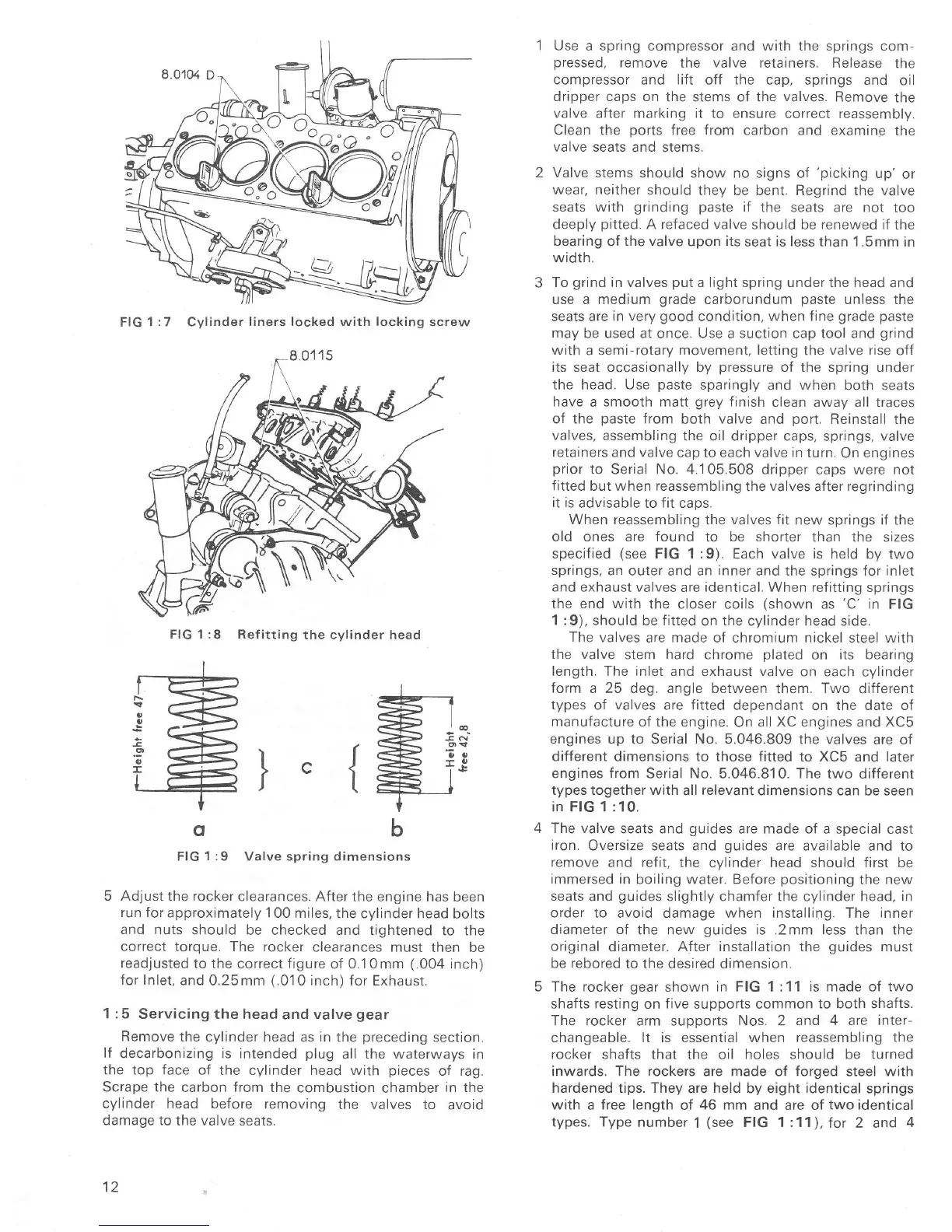

FIG

1 :9

Valve spring dimensions

5 Adjust

the

rocker

clearances. After

the engine has been

run Íor

approximately 1

00

miles,

the cylinder head

bolts

and nuts

should be checked and

tightened to the

correct torque. The rocker

clearances must

then be

readjusted to

the correct figure

of 0.10mm

(.004

inch)

Íor

Inlet, and

0.25mm

(.01

0 inch) Íor Exhausr.

1 :5

Servicing the head

and

valve

gear

Remove

the cylinder head

as

in

the

preceding

section.

lf

decarbonizrng is intended

plug

all the waterways

in

the top face oÍ

the cvlindeÍ head with

pieces

of rag.

Scrape the

carbon

from

the

combustion chamber

in

the

cylinder head

before removing

the valves

to avoid

damage to

lhe valve seats.

12

Use a spring compressor and with the springs com-

pressed,

remove

the

valve

retainers. Release

the

compressoÍ

and

lift

off

the

cap, springs and

oil

dripper caps on

the stems of the

valves.

Remove

the

valve

aÍter

marking it

to ensure correct reassembly.

Clean the

ports

free from carbon and examine

the

valve seats

and stems.

Valve stems should

show no signs of

'picking

up'

or

weaÍ, neither should

they be bent. Regrind

the

valve

seats

with

grinding

paste

if

the seats

are

not

too

deeply

pitted.

A refaced valve should

be

renewed if

the

bearing of the valve

upon its

seat

is less

than 1.5mm in

width.

To

grind

in valves

put

a

light spring

under the head and

use a medium

grade

carborundum

paste

unless the

seats are in very

good

condition, when fine

grade paste

may

be used at once. Use a suction cap tool and

grind

with

a semi-rotary

movement, letting

the

valve rise

ofÍ

its seat occasionally by

pressure

of the spring under

the head. Use

paste

sparingly and when

both seats

have

a

smooth matt

grey

finish

clean

away all

traces

of the

paste

from

both

valve

and

port.

Reinstall the

valves, assembling

the oil dripper caps, springs, valve

retainers and valve

cap to each

valve

in turn.

On

engines

prior

to Serial No, 4.105.508 dripper

caps were

not

Íitted

but when reassembling

the

valves

after regrinding

it is

advisable to f it caps,

When reassembling

the

valves fit

new springs iÍ the

old ones are found

to

be shorter

than the sizes

specified

(see

FIG 1:9). Each valve is

held by two

springs,

an outer and an

inner

and the springs Íor inlet

and exhaust valves

are

identical.

When refitting springs

the end

with

the closer coils

(shown

as

'C'

in

FIG

1 :9), should

be

fitted

on the cylinder head side.

The

valves are made of

chromium

nickel

steel with

the

valve

stem hard chrome

plated

on

its bearing

length. The inlet

and exhaust

valve

on each

cylinder

form

a 25 deg.

angle

between

them.

Two

difÍerent

types

of

valves

are

Íitted

dependant

on

the date

of

manufacture of the engine.

On

all XC

engines and

XC5

engines up to

Serial

No.

5.046.809 the valves

are of

diÍferent dimensions

to those

Íitted

to

XC5

and later

engines from Serial No. 5.046.81

0.

The

two different

types together with

all

relevant

dimensions can

be seen

in FIG

1

:10.

The valve

seats and

guides

are made of

a special cast

iron.

Oversize seats and

guides

are available and

to

remove

and

refit,

the cylinder head should first be

immersed in

boiling water. Before

positioning

the new

seats

and

guides

slightly chamÍer the cylinder head,

rn

order to avoid

damage

when installing. The inner

diameter of

the new

guides

is

,2mm

less

than the

original

diameter.

AÍter installation

the

guides

must

be rebored

to the desired dimension.

ïhe

rocker

gear

shown

in

FIG 1:11

is made

of

two

shaÍts

resting

on

five

supports common

to both shafts.

The

rocker arm suDoorts Nos. 2

and 4 are inter-

changeable. lt is essential when reassembling

the

rocker shafts that

the oil

holes should be turneo

inwards. The rockers are made of forged

steel

with

hardened tips. They

are

held

by eight identical springs

with

a

free length

of

46

mm and are of

two identica.

types; Type

number

1

(see

FIG 1:11),Íor

2 and

4

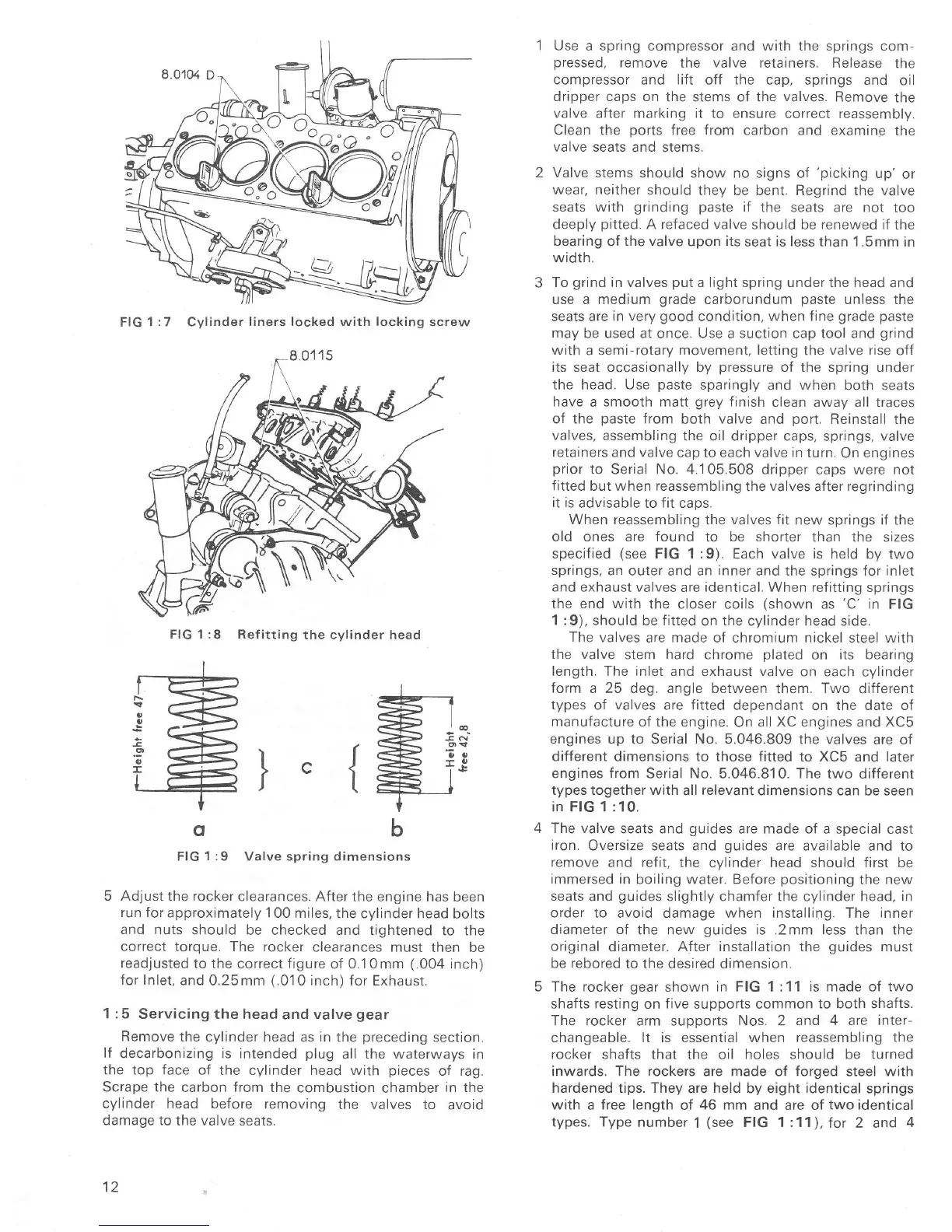

FIG

1 :7

Cylinder

liners locked with locking screw

FIG 1:8 ReÍitting

the cylinder head

Loading...

Loading...