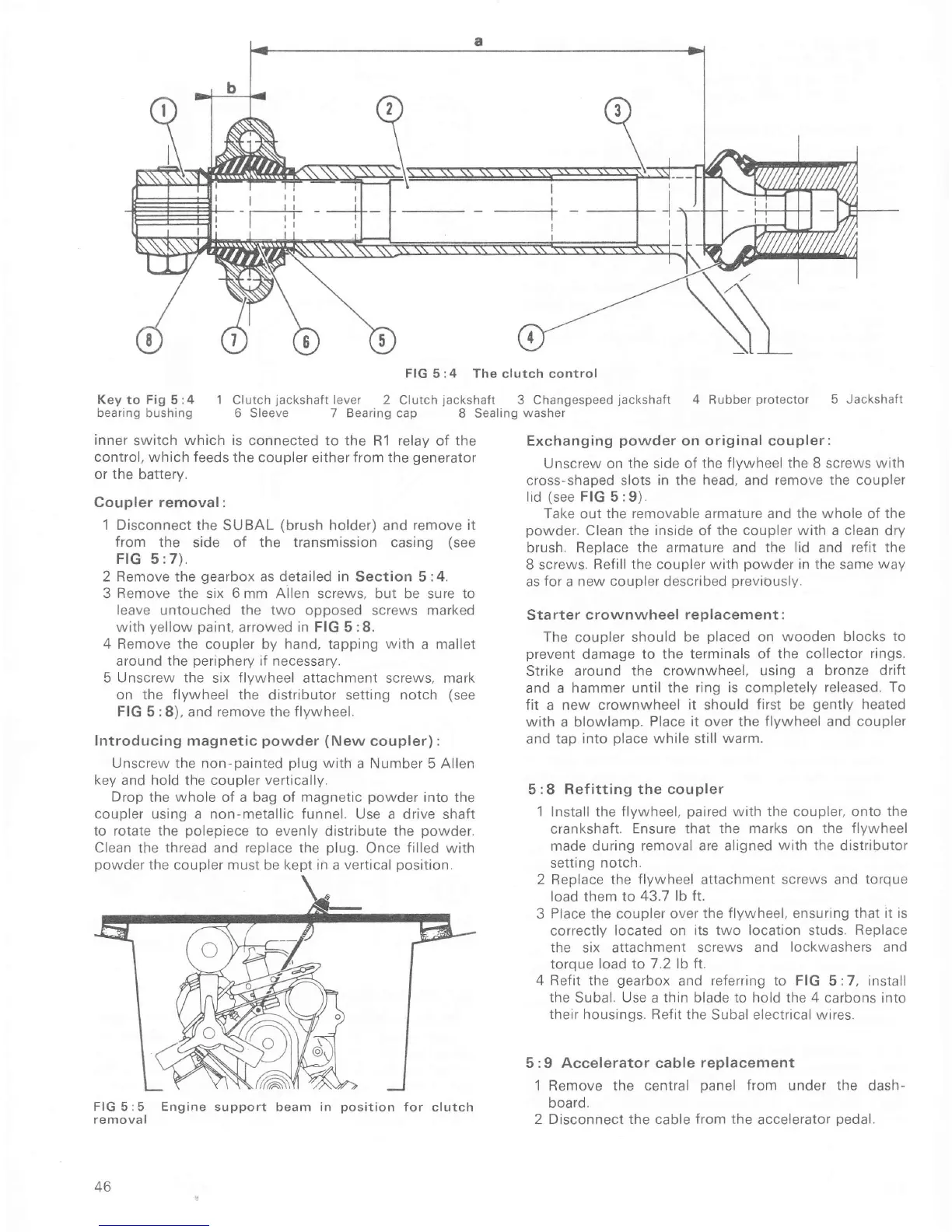

FIG

5:4 The clutch control

Key to Fig 5 :4 1 Clutch

jackshaft

lever 2 Clutch

jackshaÍr

3 Changespeed

jackshaft

bearing bushing 6 Sleeve 7 Bearing cap

8 Sealing

washer

inner

switch

which is

connected to the

R1

relav

of

the

control, which feeds the

coupler

either

Írom the

generator

or the

battery.

Coupler removal:

1 Disconnect

the SUBAL

(brush

holder)

and

remove it

from

the side of the transmission casing

(see

FIG

5

:7).

2 Remove

the

gearbox

as detailed in

Section 5:4.

3

Remove the

six

6

mm

Allen

screws, but be sure to

leave untouched the two opposed

screws

marked

with

yellow paint,

arrowed in FIG 5 :8.

4 Remove the

coupler by

hand,

tapping

with

a mallet

around the

periphery

if necessary,

5 Unscrew

the

six Ílywheel attachment screws, mark

on the

flywheel

the distributor setting notch

(see

FIG

5

:8),

and remove the

flywheel.

Introducing magnetic

powder

(New

coupler):

Unscrew the non-painted

plug

with

a Number 5 AIlen

key and hold the coupler vertically.

Drop

the

whole

of a bag oÍ

magnetic

powder

into the

coupler using a non-metallic funnel.

Use a drive shaft

to rotate the

polepiece

to

evenly distribute

the

powder.

Clean

the

thread and replace the

plug.

Once

filled

with

powder

the coupler must be kept in a vertical

position.

4 Rubber Drotector

5

Jackshaft

Exchanging

powder

on

original

coupler:

Unscrew on the side of

the flywheel the

8

screws with

cross-shaped

slots in the head, and íemove the coupler

lid

(see

FIG 5 :9).

Take out the

removable

armature and

the whole

of

the

powder.

Clean

the inside

oÍ

the coupler with a clean

dry

brush, Reoiace

the

armature and

the lid

and

reÍit the

B

screws. Refill lhe coupler with

powder

in the same

way

as

for

a new

coupler

described

previously.

starter crownwheel

replacement :

The

coupler

should be

placed

on wooden blocks to

prevent

damage to the teíminals

of the collector

rings.

Strike around

the crownwheel, using a

bronze drift

and a

hammer until the ring

is

completely

released. To

fit

a new crownwheel

it should

first

be

gently

heated

with

a

blowlamp. Place it over

the flywheel and coupler

and tap

into

place

while still

warm.

5

:8 Refitting the coupler

1 Install

the

flywheel,

paired

with the coupler. onto the

crankshaft.

Ensure that the marks on

the flywheel

made during

removal are aligned

with the

distributor

setting

notch.

2 Replace

the flywheel

attachment

screws and

torque

load them

to 43.7

lb Ít.

3

Place

the coupler

over the

flywheel,

ensuring

that rt is

correctly

located on its two

location

studs.

Replace

the

six

altachment screws and

lockwashers and

torque load to

7.2 lb Ít.

4 Refit

the

gearbox

and

reÍerring to FIG

5:7,

install

the

Subal.

Use

a

thin

blade to hold the 4 carbons

into

their housings. Refit

the Subal electrical wires.

5:9 Accelerator cable

replacement

1

Remove

the central

panel

from

under

the

dash-

board.

2 Disconnect the cable from the

accelerator oedal.

FIG 5:5 Engine support

beam

in

position

Íor

clutch

removal

46

Loading...

Loading...