9

:9 Ref itting

the

rack

and

pinion

unit

1 Position the rack

assembly against

the

crossmember

and fit the two attachment screws. Tighten to

a

torque

of

22 Ío

32

lb

ft. lt will

be

necessary to

dis-

connect

the Íront engine

mountings

in

order tb apply

a torque wrench to these screws. Reconnect the

mountings after tightening the

rack

assembly screws.

2 Reconnect the steerrng at the flexible coupling

and

tighten the

yoke

bolt

to a torque

of

5,5

to

9lb ft. Lock

the

bolt

by

peening.

3

Fit the steering connecting links in

the

steering arms

and tighten

the

ball

joint

nuts to 36 to

40 lb

ft and

lock with splitpins..

4

Bring the

right

hand connecting link into

position

and

Íit

and tighten

the eye bolt and

nut.

5

Adjust the Íront

wheel alignment

to .079+ .039 inch

toe-in

by screwing

the

ball

head nut

on the

lefthand

connecting

link

in or out. Tighten the locknut

against the ball head nut.

6 Fit and secure the

rubber

boots on the rack housrno

and connecting links-

7 Check the installation by turning the steering wheel

Írom

lock

to

lock.

8 Check

the

steering

wheel

position

in the straight-

ahead

position

and correct as

necessary

by

removing

and

repositioning the

wheel.

9:10 Road testing the steering

Drive the car at about 30

mile/hr

and

then

take

vour

hands

ofÍ the

steering

wheel. The

car should maintain

a straight course. lÍ the road is crowned, it

may cause

rhe car to wander towards the low side of

the

road

and.

thereÍore, it may be necessary to

make

this

test straddled

over the centre

line.

Uneven

front

end angles will cause

the car to

wander

to one side.

Hold

your

hands lightly

on

the

steering wheel at about

30

mile/hr to check whether

any

shocl<s

are being trans-

mitted

back

to the steering

wheel.

A.constantly

jiggling

wheel inciicates that the front wheels are out of

balance.

Apart from being tiring to the driver on.a

long

journey

this movement

is

bound to accelerate wear

on everv

moving

part

of the front end.

With the car moving at about 25 milelhr turn

through

90 deg. and

then release the

steering

wheel. lt

should

come back to the straightahead

position

without any

assistance

from the

driver.

lÍ it

does not

il indicates

binding

in the linkage, insufÍicient caster

or

insufficient

steering

axis inclination.

To

check

for misalignment,

inspect the front

tyres

for

uneven tread

wear.

Sharp

edges Íelt

going

one

way are

called

feather edges and are developed

Írom

sideways

scufÍing often due

to incorrect toe-in.

I

:11

Fault

diagnosis

(a)

Wheel wobble

1 Unbalanced

wheels and tyres

2

Slack

steering connections

3

Incorrect steering

geometry

4 Excessive

play

in

steering

gear

5 Weak

front springs

6 Worn hub bearings

P404

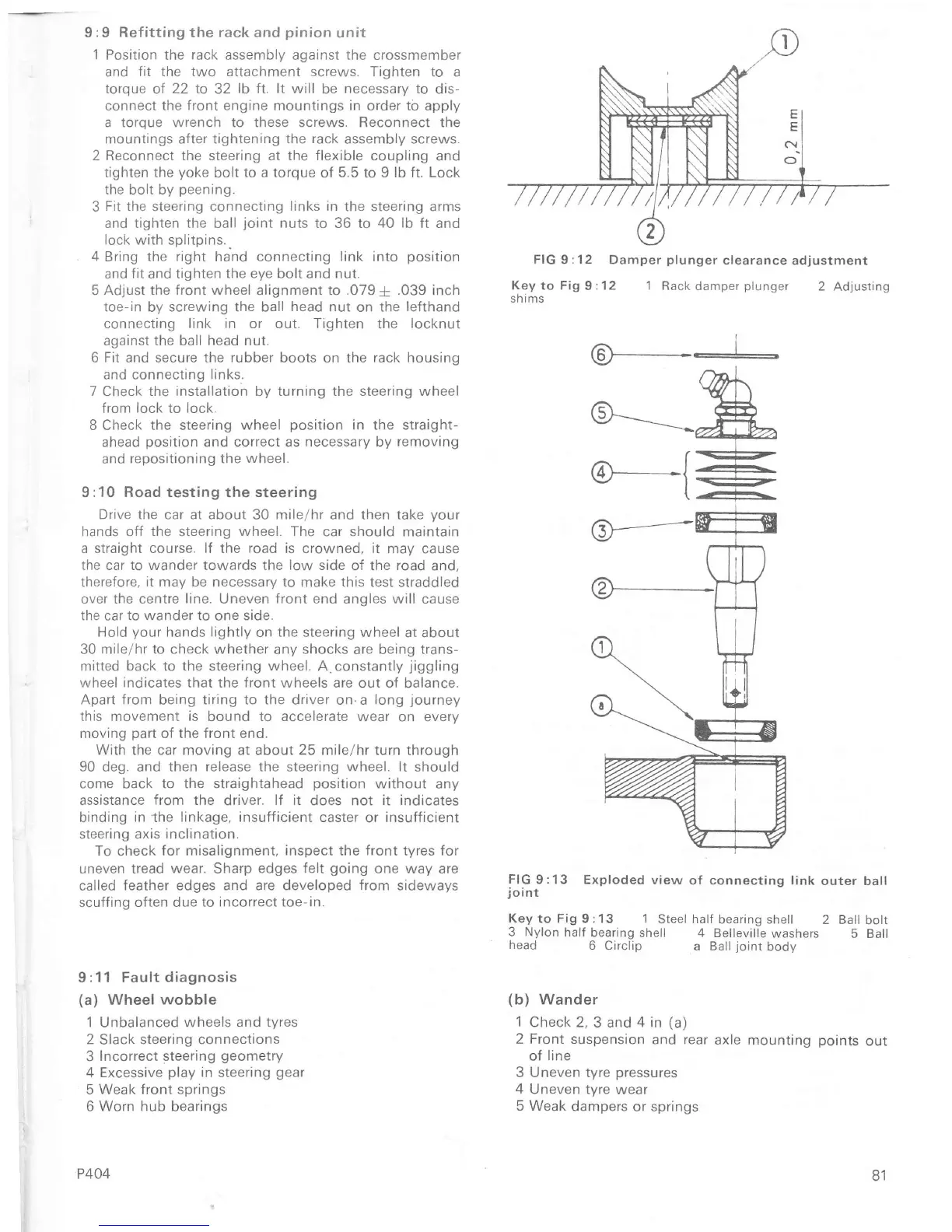

Key ro Fig

I

:12

snrms

1 Rack

damper

plunger

2 Adjusting

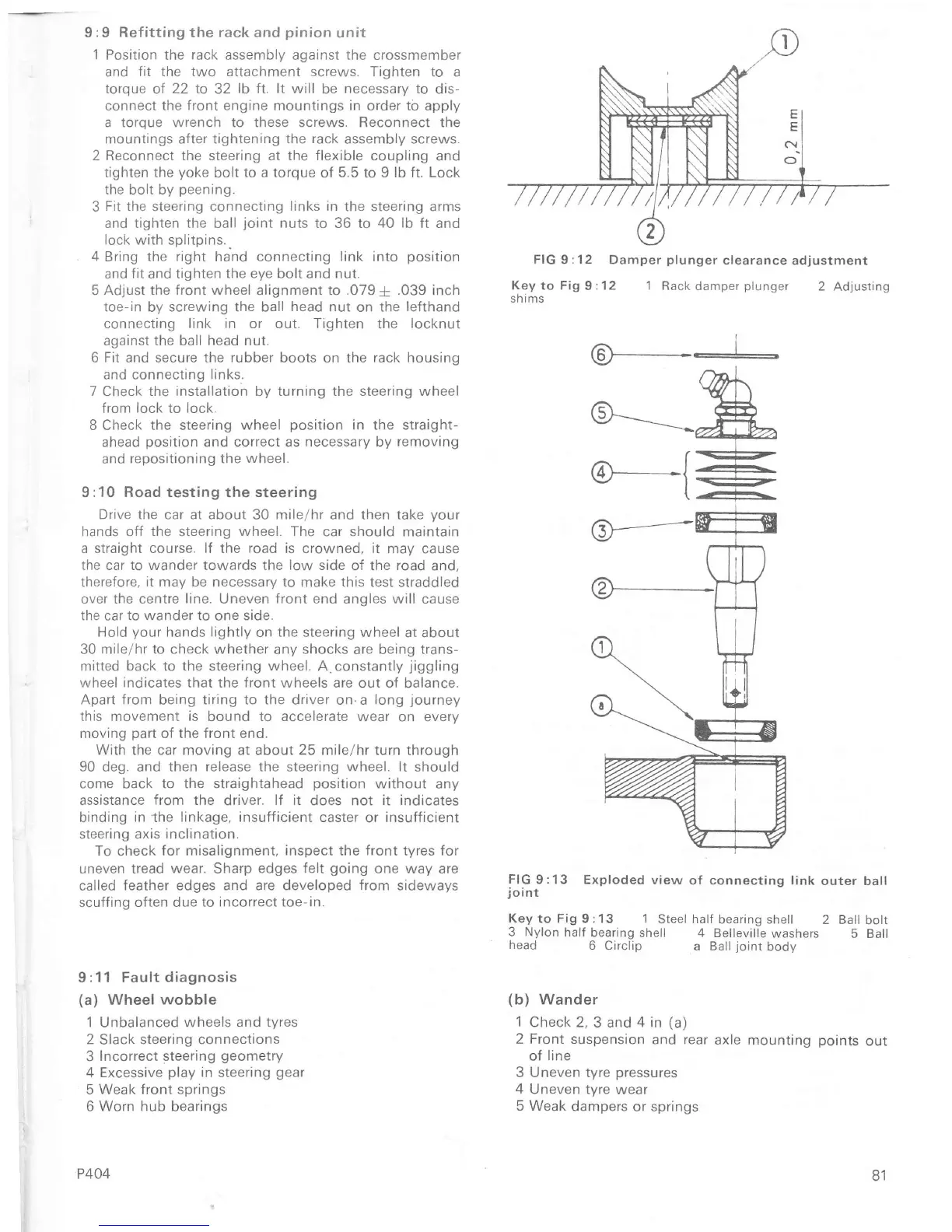

FIG

9:13 Exploded

view

of

connecting

link

outer ball

joint

Key

to Fig I :1

3

1

Steel

half

bearing shell

2 Ball bott

3 Nylon half

bearing

shell 4 Belleville

washers

5 Ball

head

6 Circlip

a

Ball

joint

body

(b)

Wander

1

Check 2,

3

and 4 in

(a)

2 Front suspension

and rear

axle mountrng

points

out

of

line

3 Uneven tyre

pÍessures

4 Uneven tyre

wear

5

Weak dampers or springs

FIG 9 :1 2

Damper

plunger

clearance

adjustment

81

Loading...

Loading...