f

exceed

20 to

25mm

(.079

to.099 inch).

This is due

to a modiÍication

of the castellated

nut.

6

Install and tighten

the castellated

nut to a

torque of

44

to 50 lb ft.

7 Remove

the nyloc

nut and special spacer

F from

the

shock

absorber

rod.

Work the rod in and out

to check

for free sliding

and rotation

movement,

leaving the

rod

in

the

extended

position.

8 Re-install

the

pivot

bearrng

ball cage and

lubíicate

with multi-purpose

grease.

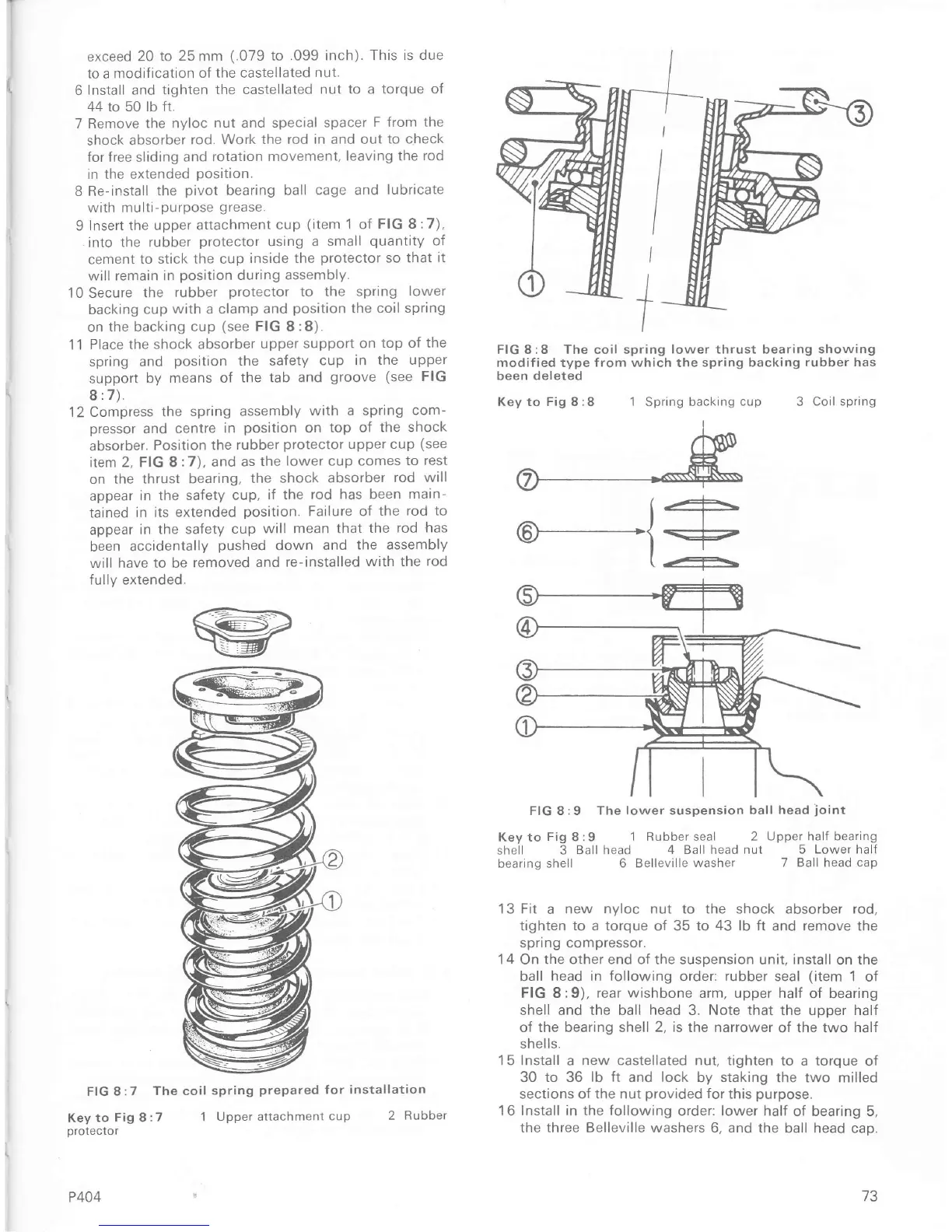

9

Insert the upper attachment

cup

(item

'l

of

FIG 8:7),

into the

rubber

protector

using

a small

quantity

of

cement

to stick the cup

inside the

protector

so that

it

will remain in

position

during

assembly.

10 Secure

the

Íubber

protector

to the

spring

lower

backing

cup

with

a

clamp

and

position

the

coil spring

on

the backing cup

(see

FIG

8

:8).

1

1 Place the shock

absorber

upper

support on

top oÍ

the

spring and

position

the safety

cup in

the upper

support

by means

of

the tab and

groove

(see

FIG

8:7).

12

Compress

the spring

assembly

with a spring

com-

pressor

and centre

in

position

on top of

the shock

absorber.

Position

the

rubber

protector

upper cup

(see

item 2, FIG 8:7).

and as

the

lower

cup

comes

to rest

on

the thrust bearing,

the

shock absorber

rod will

appear

in the saÍety

cup,

if the rod has been

main-

tained

in its

extended

position.

Failure oÍ

the

rod to

appear

in the safety

cup

will mean that

the

rod has

been

accidentally

pushed

down and

the assembly

will have to be

removed

and

re-installed

with the

rod

fully extended.

FIG 8:7

Ïhe coil

spring

prepared

for installation

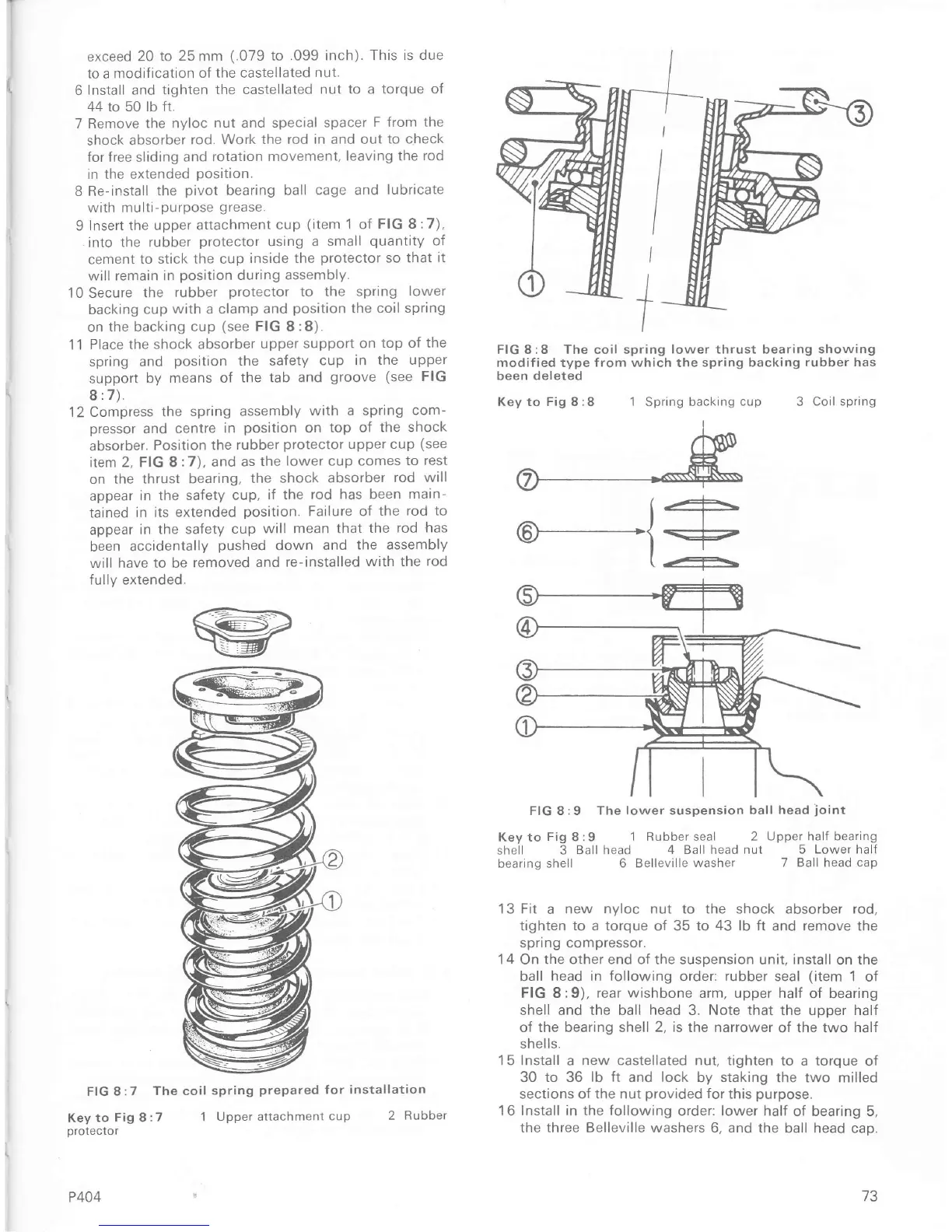

FIG 8:8 The coil spring

lower thrust bearing showing

modif ied type

f rom

which the spring

backing rubber has

been deleted

Key to Fig I

:8

1 Spring backing

cup

3

Coil spring

r-ê-

O-j

--

---

FIG 8:9 The

lower suspension

ball head

joint

Key to

Fig

8:9

I Rubber seal

2 Upper halÍ bearing

shell 3

Ball head 4 Ball head

nut 5 Lower halÍ

bearing

shell 6 Belleville

washer 7

Ball

head

cap

13 Fit

a

new nyloc nut to the shock

absorber

rod,

tighten

to a

torque of 35 to

43 lb ft

and remove the

spnng compressor.

14 On the other end oÍ the suspension unit, install

on

the

ball head in following order: rubber

seal

(item

1

of

FIG 8:9),

rear wishbone

arm, upper half

of bearing

shell and the ball

head

3. Note that the

upper

half

oÍ the bearing shell

2, is

the narrower

of the two

half

shells.

15 Install a

new

castellated nut, tighten

to a torque oÍ

30 to 36

lb

ft and lock

by

staking

the two milled

sections

of the

nut

provided

for

this

purpose.

16Install in the

Íollowing

order: lower

half of bearing 5,

the three Belleville washers 6, and the

ball head cap.

Key to

Fig 8 :7

protecto

r

P404

1 Upper attachment

cup

2 Rubber

73

Loading...

Loading...