--r:

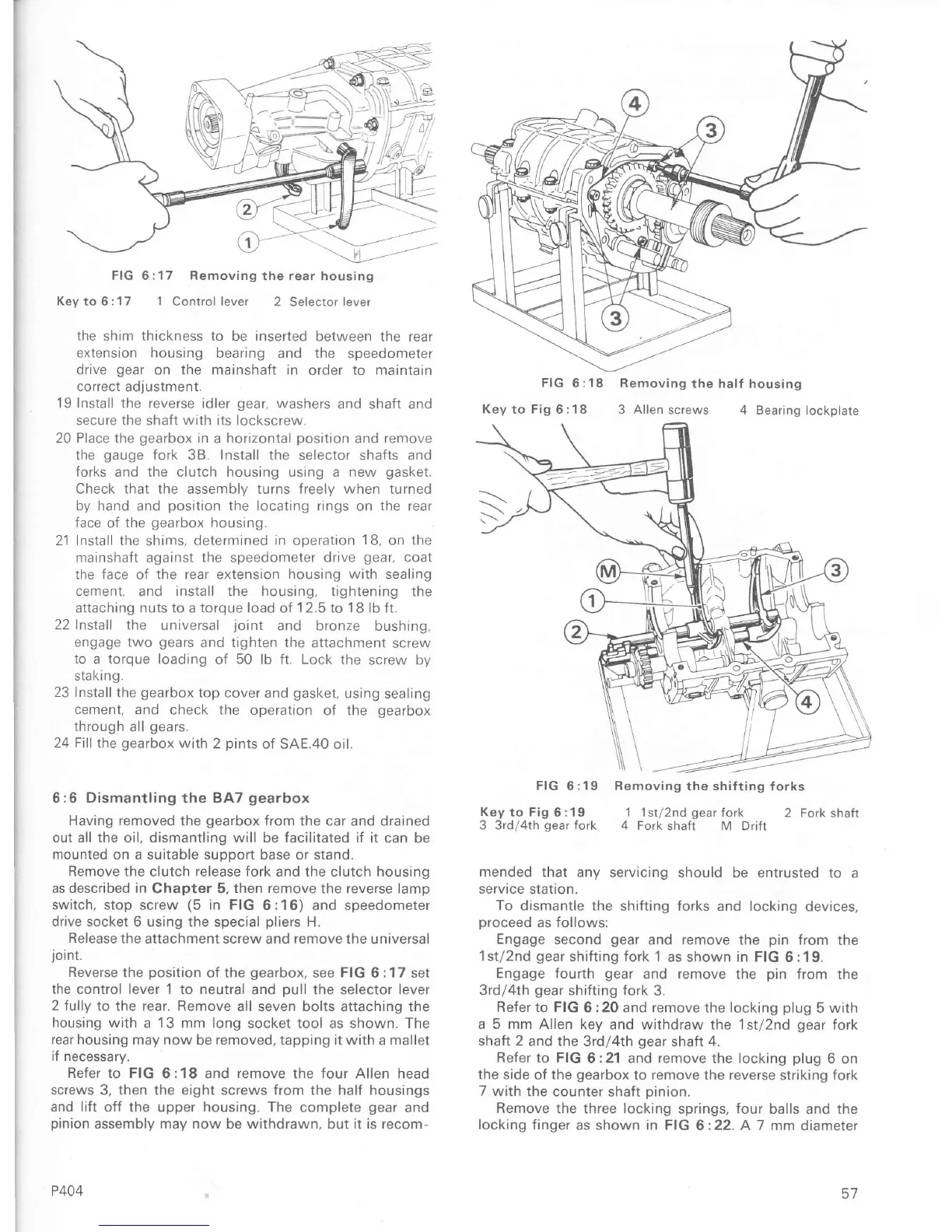

FIG 6:17 Removing

the

rear

housing

Kevto6:17 1 Controllever

2

Selectorlever

the

shim thickness to be inserted

between the rear

extension housing

bearing and the

speedometer

drive

gear

on

the mainshaft in

order to

maintarn

coÍrect

adlustment.

19 Install

the reverse idler

gear,

washers

and

shaft and

secure

the

shaÍt

with

its lockscrew.

20

Place

the

gearbox

in a

horrzontal

position

and remove

the

gauge

Íork 38.

Install

the

selectoí shafts

and

Íorks

and the clutch housing using a new

gasket.

Check that the assemblv turns Íreelv when turned

by

hand and

position

the locating

rings on

the rear

face

of

the

gearbox

housing.

21 Install the shims, determined

in

operation

18,

on the

mainshaÍt against

the

speedometer

drive

gear,

coat

the Íace

oÍ

the rear extension housing

with

sealing

cement, and

install the

housing,

tightening

the

attaching nuts to a torque load of 12.5 to 1B lb ft.

22

Instali the

universal

joint

and bronze bushing,

engage two

gears

and tighten the

attachment

screw

to

a torque loading

oÍ

50

lb ft. Lock the

screw by

slaKrng,

23 Install

the

gearbox

top cover

and

gasket,

usrng

sealing

cement,

and check the

operation oí the

gearbox

through

all

gears.

24 Fill

the

gearbox

with

2

pints

of

SAE.40 oil.

6 :6 Dismantling the BA7

gearbox

Having removed

the

gearbox

Írom the car and drained

out all the

oil,

dismantling will

be

facilitated if it

can be

mounted

on a suitable suppoÍt base

or

stand.

Remove

the clutch

release

fork and the clutch housing

as descÍibed in

Chapter 5,

then remove

the

reverse

lamp

switch, stop

screw

(5

in FIG

6:16) and speedometer

drive

socket 6 using the special

pliers

H.

Release

the

attachment screw and

remove

the universal

joint.

Reverse

the

position

of the

gearbox,

see

FIG

6

:1 7

set

the

control lever 1 to neutral

and oull the selector lever

2 fully

to the rear. Remove

all seven bolts attaching the

housing with

a 13

mm long

socket tool as shown. The

rear housing

may now be removed,

tapping

it with

a mallet

iÍ

necessary.

Refer

to

FIG

6:18 and

remove

the four Allen head

screws

3, then the eight screws from

the

halÍ housings

and liÍt

oÍf the upper housing. The

complete

gear

and

pinion

assembly may now be withdrawn,

but

it is recom-

P4O4

3 Allen screws

4 Bearing

lockplate

Key to Fig

6

:19

3

3rdl4th

gear

Íork

FIG

6:19 Bemoving the shifting

forks

1 lst/2nd

gear

Íork

2 Fork

shaft

4 Fork

shaft M DriÍt

mended

that any

servicing should be entrusted

to a

service station.

To

dismantle the

shiÍting

forks

and locking

devices,

pÍoceed

as follows:

Engage

second

gear

and

remove

the

pin

Írom

the

1st/2nd

geaÍ

shifting fork

1 as shown in FIG

6 :

'l

9.

Engage Íourth

gear

and

remove

the

pin

from the

3rdl4th

gear

shifting fork

3.

Refer to FIG

6 :20 and Íemove the locking

plug

5 with

a 5 mm Allen key

and withdraw the 1st/2nd

gear

foÍk

shaft

2

and the

3rd/4th

gear

shaft

4.

Refer to FIG

6:21 and remove the locking

plug

6 on

the side

of the

gearbox

to remove the reverse

stÍiking fork

7 with

the counter

shaÍt oinion.

Remove

the three locking

springs,

four

balls

and

the

locking finger

as shown in FIG

6:22. A7 mm

diameter

FIG

6

:18

Removing

the halÍ housing

Key to Fig

6

:1

8

^-7

Loading...

Loading...