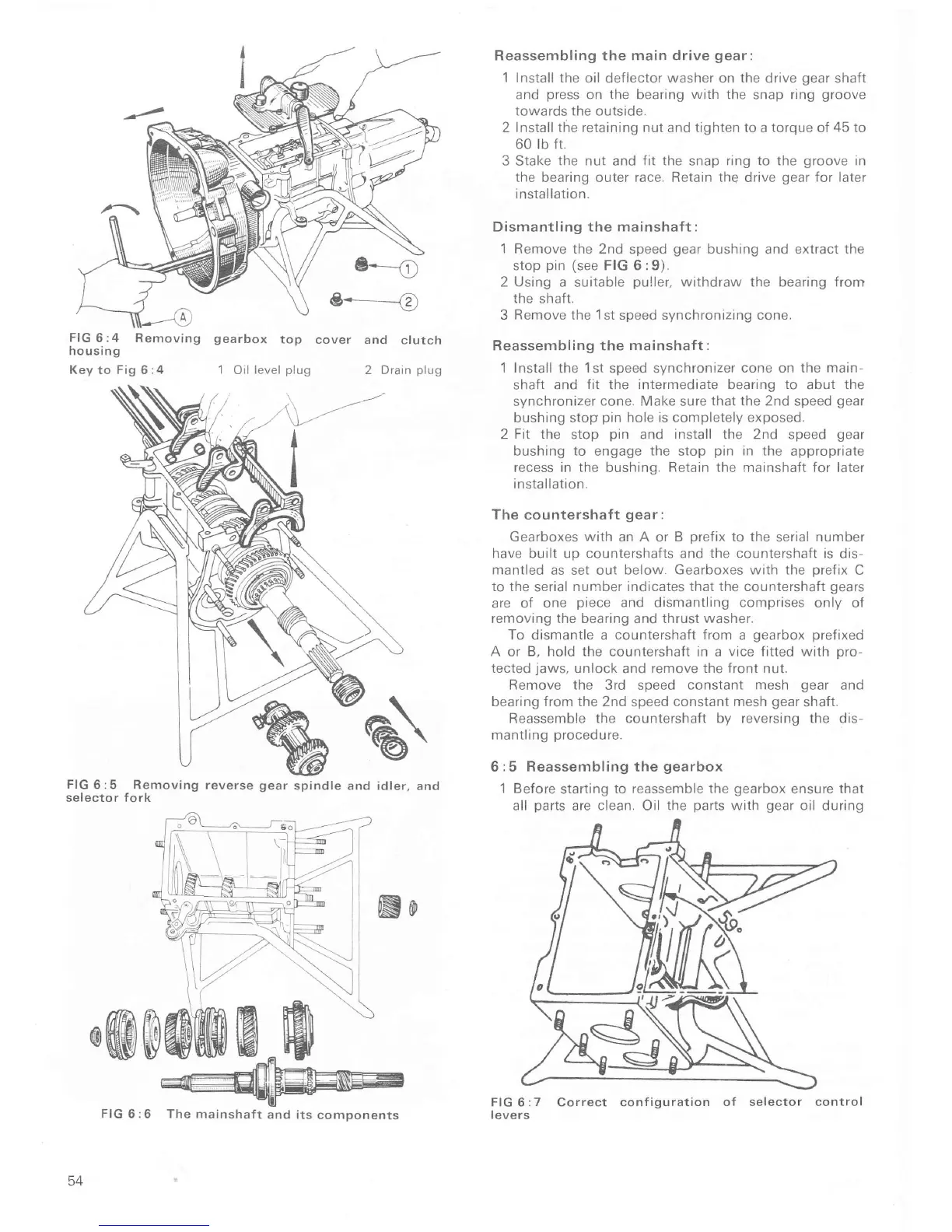

FlG6:4

Removing gearbox

top

cover

housi

ng

Key to

Fig

6:4

'l

Oil

level

plug

and clutch

2 Drain

plug

à

FIG

6:5 Removing reverse gear

spindle and idler,

and

selector fork

No

*@&

Reassembling the main drive

gear:

1

Install the oil

deflector

washer

on

the

drive

gear

shaft

and

press

on the bearing

with

the snap ring

groove

towards the

outside.

2 Install the retaining nut and tighten to a torque of

45

to

60 tb fr.

3

Stake

the nut

and

fit the

snap

ring to the

groove

in

the bearing outer

race.

Retain

the

drive

gear

for later

installation.

Dismantling

the mainshaft :

1

Remove the

2nd speed

gear

bushing

and

extract the

stop

pin

(see

FIG 6 :9).

2 Using

a suitable

puller,

withdraw the bearing from

the shaÍt.

3 Remove the

1

st speed synchronizing cone.

Reassembling the mainshaft

:

1 Install

the

1st

speed synchronizer

cone on the

main-

shaft

and fit the intermediate bearing

to

abut the

synchronizer

cone.

Make sure

that the 2nd speed

gear

bushing

stop

pin

hole is completely exposed.

2

Fit the

stop

pin

and

install

the 2nd speed

gear

bushing

to

engage

the

stop

pin

in the

appropriate

recess in

the

bushing.

Retain the

mainshaft for later

installation.

The countershaft

gear:

Gearboxes with

an A or

B

prefix

to the

serial

number

have built up countershaÍts and

the

countershaft is dis-

mantled

as set out

below. Gearboxes with the

orefix C

to the

serial

nurnber indicates that the countershaft

gears

are oÍ

one

piece

and dismantling comprises

only oÍ

removing the bearing

and

thrust washer.

To dismantle a countershaÍt

from

a

gearbox prefixed

A or

B,

hold

the

counteÍshaÍt in a

vice

fitted with

pro-

tected

jaws,

unlock

and remove

the Íront

nut.

Remove

the

3rd speed

constant mesh

gear

and

bearing from the 2nd

speed

constant mesh

gear

shaft.

Reassemble

the countershaÍt by reversing the dis-

mantlrng

procedure.

6

r5

Reassembling the

gearbox

1

Before

starting

to reassemble the

gearbox

ensure that

all

parts

are clean. Oil

the

parts

with

gear

oil during

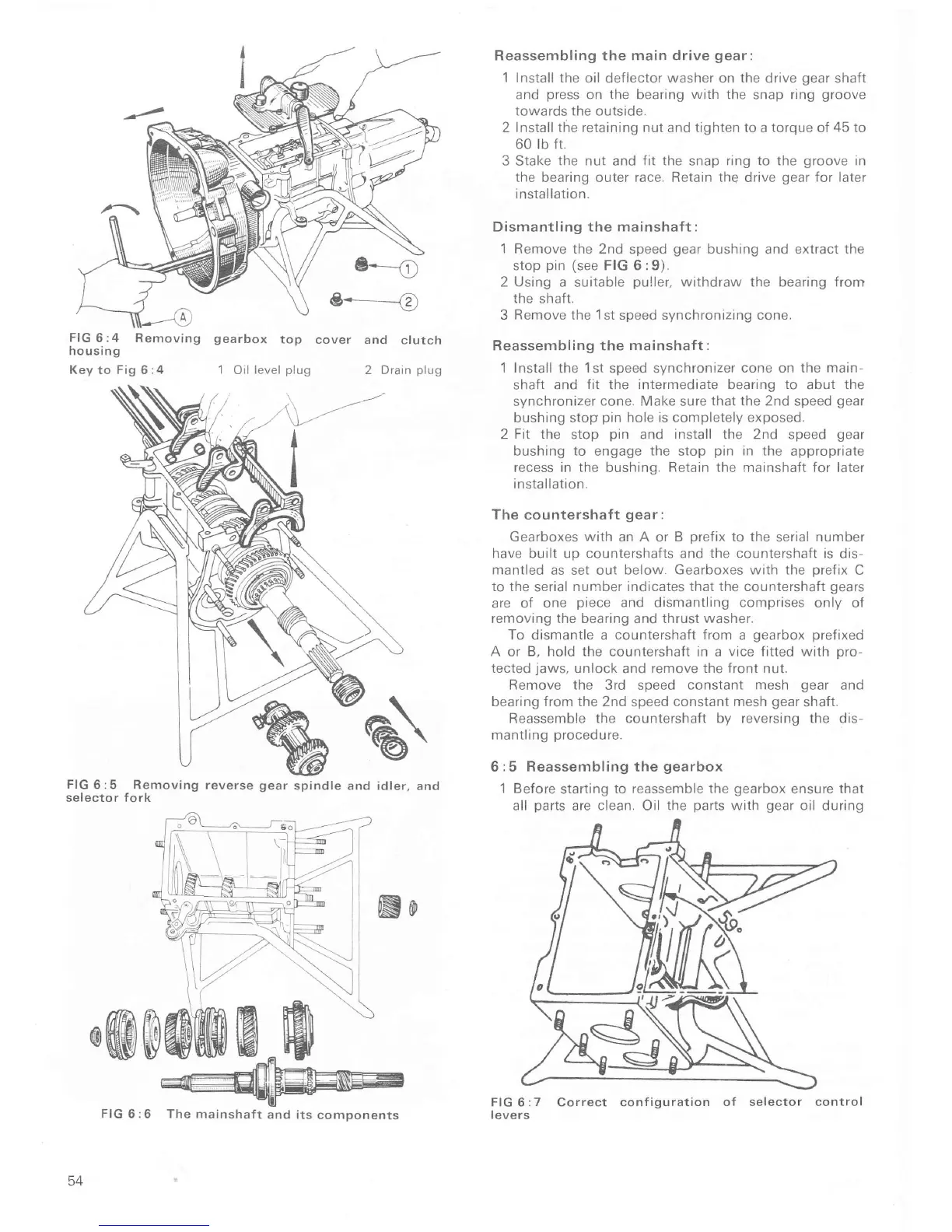

CoÍrect configuration

oÍ selector

The mainshaÍt

and its

components

54

FIG 6:6

control

Loading...

Loading...