7

Screw on a new ball head

housing,

tighten to a torque

oÍ

30

to 46 lb ft

and lock

by staking.

8 Install

the

pinion

ballbearing in

the rack

housing

and

fit the retaining

clip.

I

Fit

the flexible

coupling to the

pinion,

tighten

and

lock

the

bolts.

'1

0Insert the rack in

the housing

and

position

it

so that

the end

opposite the

ball

head

protrudes

by 98 mm

(3.846

inches)

as shown in FIG

g

:7.

11 Installthe

pinion,

fitted with

a new

O-ring sealso rhat

the

yoke

holes are

aligned

as shown in

FIG

9:7.

Fit

a

new

pinion

nut, tighten to a torque

of 11 to 14 lb ft

and

lock

by staking. Fit the housing

cap.

12 Refer to

Section 9:7 and determine the thickness

of

the

shims to be

inserted

between

the damper

Ílange

and the thrust

spacer of

the

damper, at the

pinion

end

oÍ the rack.

13 Install the rack

dampers and tighten the f lange

screws

to a torque of

7.25

to 9

lb

ft.

14 Check for

stiffness by operating the rack in

both

directions and Íit the rubber

boots,

15

Screw ïhe

leÍthand

connecting ltnk

and

locknut

onto

the rack

ball shank so that

a 24mm

(.945

inch)

dimension exists between the

ball head housing and

the locknut,

with the connecting link

aligned

with

the

rack

centre

line

(see

FIG 9:8). Tighten

the

locknut

íinger

tight.

16

Screw

the rack

eye

into

the righthand

of

the rack

so

that

ïhe threaded

portion protrudes

by 9.5 to 1

'1

mm

(.374

to

.433 inch),

with the locknut

against the rack

end Íace

(see

FIG

9:9).

Note

that the eyebolt

and

locknuls

are

left finger

tight for

a.ljustment

of the wheel

alignment

after

the

assembly

has been

installed

in the

car.

9

:6

Adjusting the steering rack

ball

head

1 Fit

the special adjusting clanrp, tool No.

BO704C, onto

the steeÍing racl<. The clamp is item

C oÍ FIG

9

:10.

2

Screw on a new ball head housing

2

(see

FIG

9

:1

0),

and

tighten to a torque oÍ

30

to

36

lb fr.

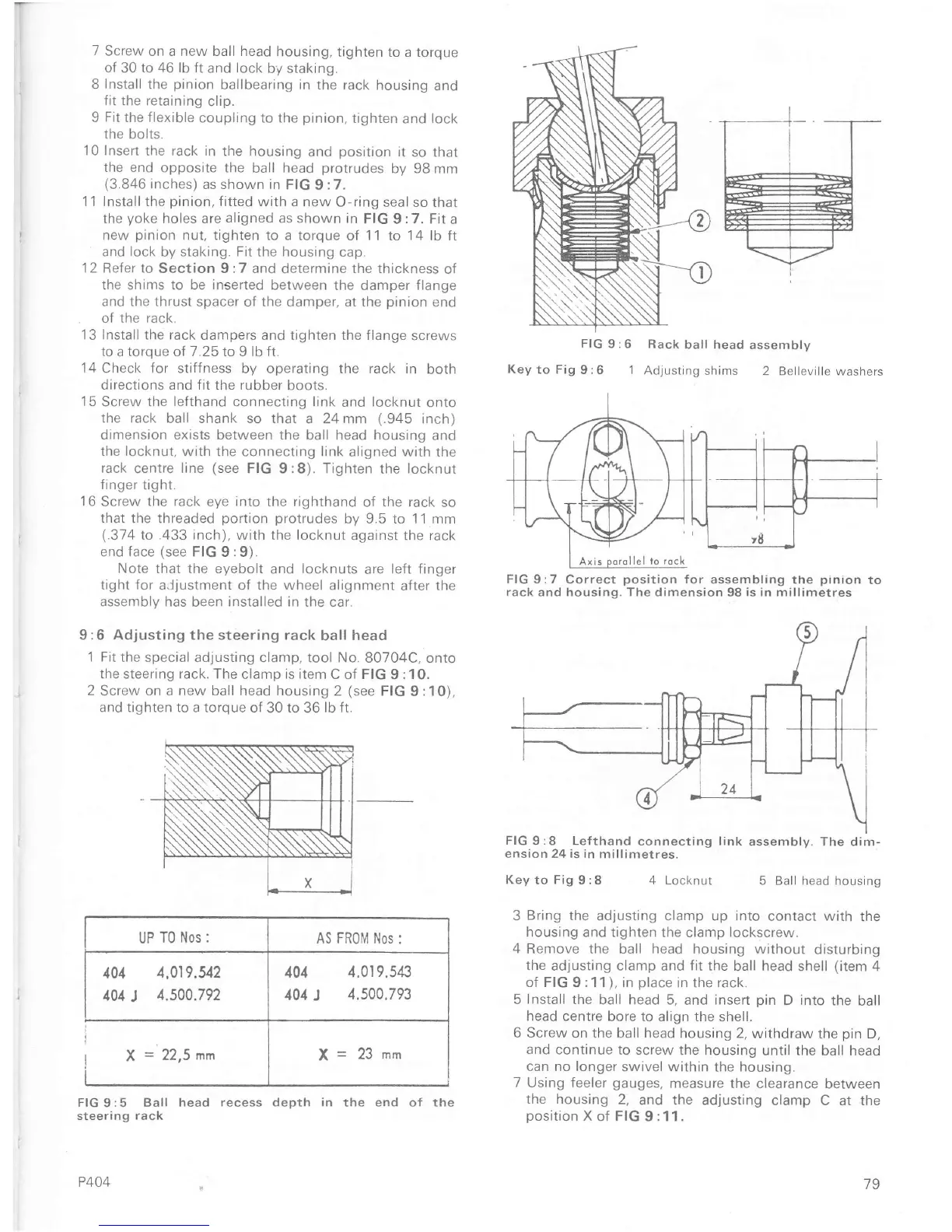

FlG9:5 Ball head

recess depth in the end oÍ the

steering rack

P404

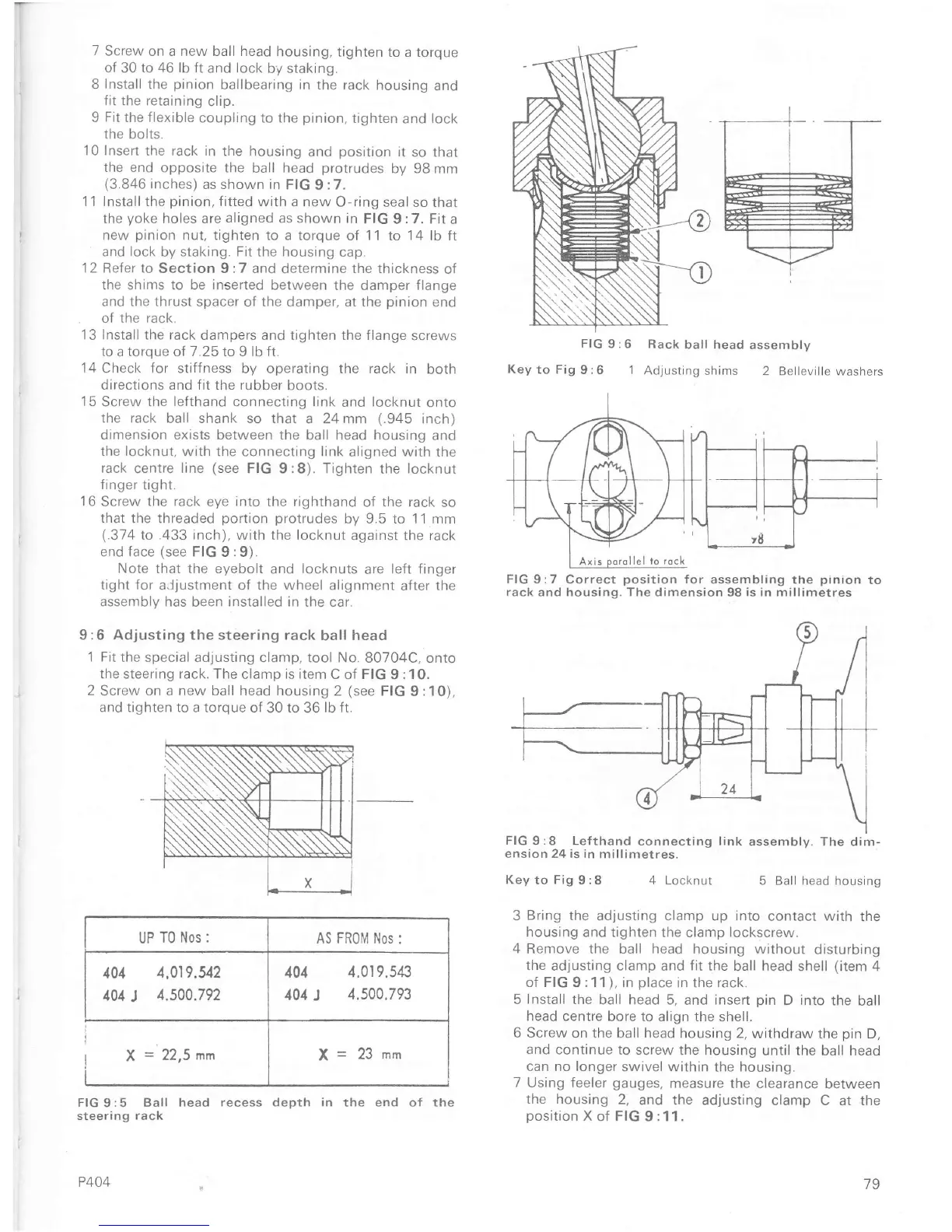

FIG

9:6 Rack

ball head

assembly

Key

to Fig

9:6 1

Adjusting

shims 2

Belleville washers

FIG 9:7 Correct

position

Íor

assembling the

pinion

to

rack and housing. The dimension 98 is in millimetres

FIG

9:8 Lefthand

connectinq

ension 24

is

in millimetres.

Key

to

Fig

I :8

;sembly. The

dim-

5 Ball head

housing

4 Locknut

3

Bring

the adjusting clamp

up

into

contact with

the

housing and tighten

the clamp

lockscrew.

4

Remove the ball head housing without

disturbing

the

adjusting clamp and fit the

ball

head

shell

(item

4

oÍ FIG

9

:1 1

),

in

place

in the rack.

5

Install

the ball head

5, and rnsert

pin

D into

the

ball

head centre

bore to align the shell.

6 Screw on the ball head

housing 2,

withdraw the

pin

D,

and

contrnue to screw

the housing until

the ball head

can no longer

swivel within the houstng.

7 Using feeler

gauges,

measure

the

clearance

between

the housing

2,

and the adjusting

clamp C at the

position

X oÍ FIG

9

:11

.

link

assemblv.

UP

T0 Nos :

AS FR0IVÍ Nos

:

401

4.01

9.543

101

J

4.s00.793

4.019.U2

4.500.792

79

Loading...

Loading...