I

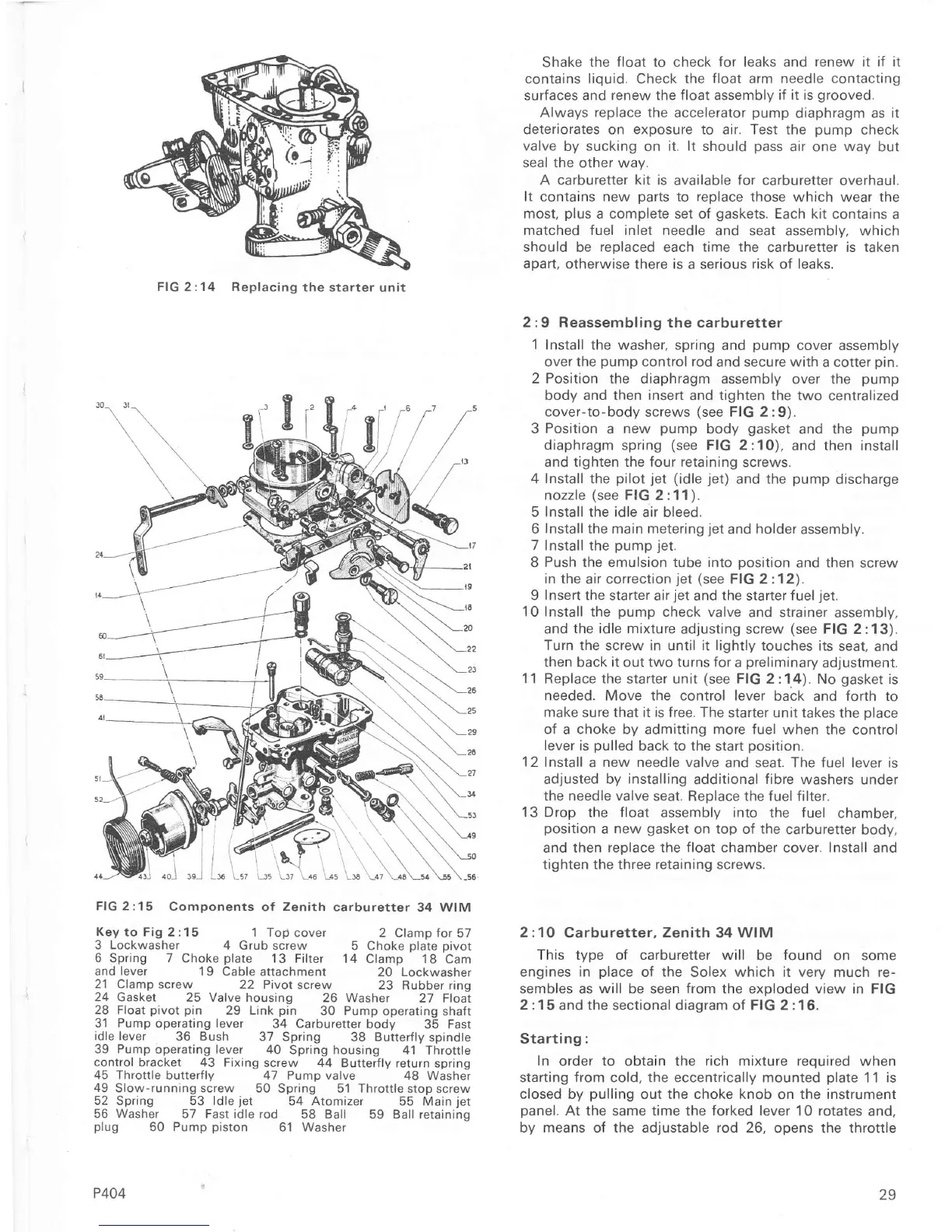

FIG 2:15

Components

of

Zenith

carburetter 34

WIM

Key

to Fig 2 : 1

5 1 Top

coveÍ 2 Clamp for

57

3 Lockwasher

4 Grub screw

5 Choke

plate

Divot

6

Spring

7

Choke

plare

13

Filter 14

Clamp 18 Cam

and leveÍ

1 9 Cable

attachment 20 Lockwasher

21

Clamp screw 22

Pivot scÍew 23

Rubber ring

24

Gasket 25 Valve housing

26 Washer

27 Float

28 Float

pivot pin

29

Link

pin

30

Pump

operating shaft

31 Pump

operating

lever

34 Carburetter body

35 Fast

idle lever

36 Bush

37 Spring

38

ButterÍly

spindte

39 Pump óperating lever

4O

Spring housing 41 Throtrle

control bracket 43

Fixing screw 44

ButterÍly return spring

45 Throttle butterfly 47 Pump

valve 48 Washer

49

Slow-running screw

50 Spring 51 ThÍottle stop screw

52

Spring 53 ldle

jet

54

Atomizer

55 Main

jet

56 Washer

57

Fast idle

rod 58 Ball

59

Ball retaining

plug

50

Pump

piston

61

Washer

P404

Shake

the float to check

for leaks and renew it iÍ it

contains liquid,

check

the float arm needle contacting

surÍaces and

renew

the

float assembly if it is

gÍooved.

Always replace

the accelerator

pump

diaphragm as

it

deterioÍates

on

exposure to

air. Test the

pump

check

valve

by sucking

on

it. lt should

pass

air one

way

but

seal the

otheÍ wav.

A carburetter kit is

available

for

carburetter overhaul.

It

contains new

parts

to

replace

those

which wear

the

most,

plus

a complete set oÍ

gaskets.

Each kit

contains a

matched fuel inlet needle

and seat assembly,

which

should be reDlaced each time the carburetter is taken

apart,

otheÍwise there is

a

seÍious risk of leaks.

2:9

Reassembling the carburetter

'1

Install the washeÍ,

spring and

pump

cover

assembly

over the

pump

control rod

and secure with a cotter

pin.

2 Position the diaphragm

assembly over the

pump

body and then

insert

and tighten the two

centralized

cover-to-body screws

(see

FIG 2:9)

3

Position

a

new

pump

body

gasket

diaphragm

spring

(see

FIG 2:10),

and tighten the Íour

retaining

screws.

4 Install the

pilot

jet

(idle

jet)

and the

pump

discharge

nozzle

(see

FIG

2:11).

5 Install the idle

air

bleed

6

Install

the main metering

jet

and

holder

assembly.

7

Install the

pump

jet.

8 Push the emulsion tube into

position

and

then

screw

in the

air correction

jet

(see

FIG 2:12).

9

Insert

the starter

air

jet

and

the starter fuel

jet.

10 Install

the

pump

check valve

and strainer

assembly,

and the idle

mixture

adjusting screw

(see

FIG 2:13).

Turn the

screw

in

until

it lightly

touches its

seat,

and

then back

it

out two turns for

a

preliminary

adjustment.

11

Replace

the

starter unit

(see

FIG

2 :1.4). No

gasket

is

needed.

Move

the

control

lever

back

and

forth

to

make sure that it is free. The

starter unit takes

the

place

of a choke by admitting more fuel

when the contÍol

lever

is

pulled

back to the

start

position.

12

Install

a

new needle valve

and

seat. ïhe fuel lever is

adjusted

by installing

additional

fibre

washers under

the needle valve

seat. Replace

the

fuel Íilter.

13 Drop

the

float

assembly into the fuel

chamber,

position

a new

gasket

on top of the

carburetter

body,

and

then reolace the float chamber cover. Install

and

tighten the three retaining screws.

2:10

Carburetter. Zenith 34 WIM

This type

of

carbuÍetteÍ will

be

found

on some

engines in

place

oÍ the

Solex

which it very

much

re-

sembles as

will

be seen

from

the exoloded view in FIG

2

:1

5 and the sectional diagram

oÍ

FIG 2 :1

6.

Starting:

In order to

obtain

the Íich mixture required

when

starting

from

cold,

the eccentrically

mounted

plate

11 is

closed by

pulling

out the choke knob on the instrument

panel.

At

the same time the

forked lever

10

rotates

and,

by

means

of the adjustable

rod

26, opens the throttle

\.T

and

the

pump

and then install

FIG

2:14 Replacing the

starter unit

f,

["

l6

29

Loading...

Loading...