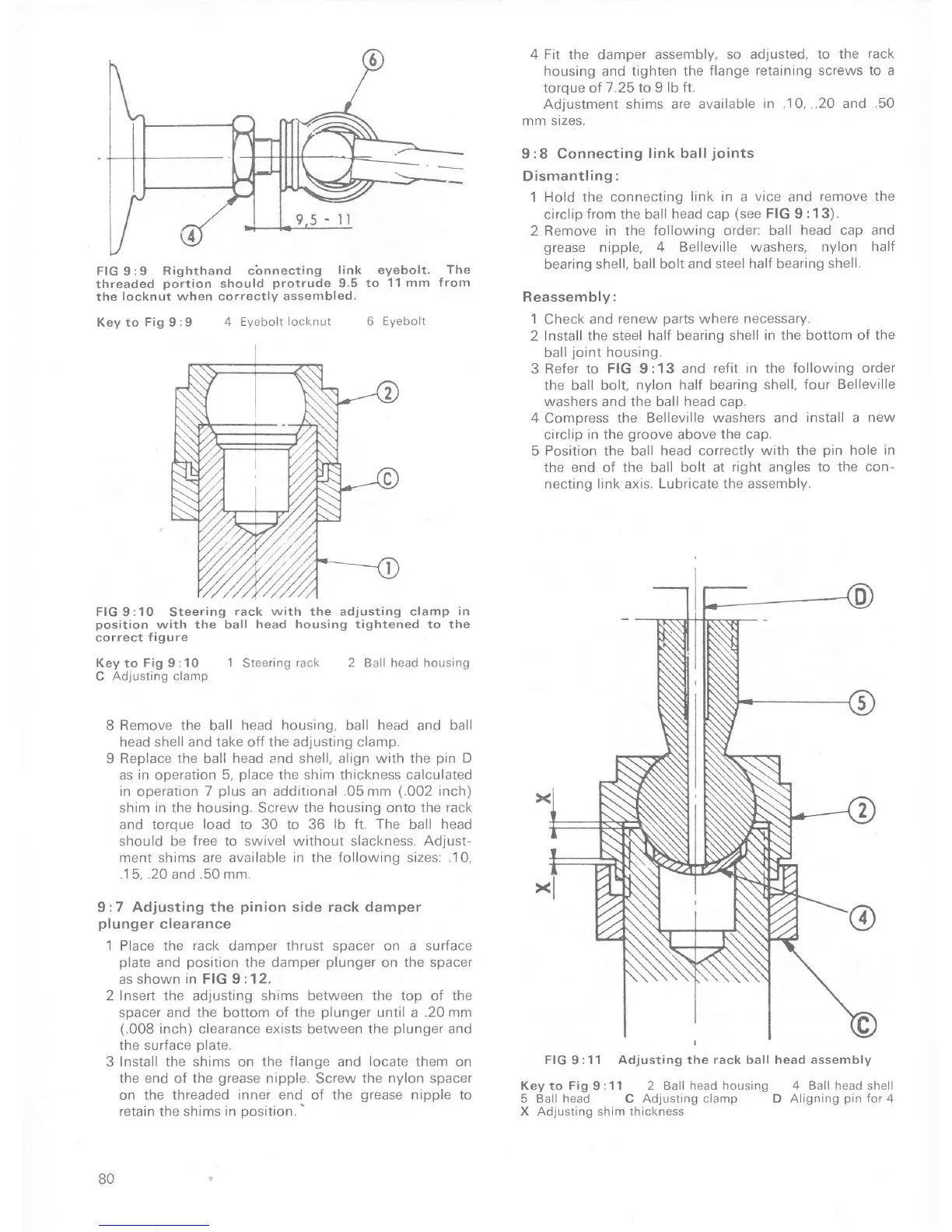

FIG

9:9

Righthand cbnnecting

link eyebolt.

threaded

portion

should

protrude

9.5

to 11

mm

the

locknut when correctly

assembled.

Key to

Fig

9:9

4 Eyebolt locknut

6 Eyebolt

4 Fit the

damper

assembly, so

adjusted, to the

rack

housing

and

tighten the

Ílange

retaining

screws

to a

torque of 7.25 to

9 lb ft.

Adjustment shims

are available

in .10,..20 and

.50

mm sizes.

9:8 Connecting

link ball

joints

Dismantling:

l Hold the connecting

link in

a

vice

and

remove

the

crrclip

Írom

the

ball

head cap

(see

FIG 9

:1 3).

2 Remove

in the Íollowing order: ball

head cap

and

grease

nipple,4 Belleville

washers, nylon

half

bearing shell, ball

bolt and steel halÍ bearing

shell.

Beassembly:

1

Check and

renew

parts

where

necessary.

2 Install the

steel half bearing shell

in the bottom oÍ

the

ball

joint

housing.

3 ReÍer

to FIG

9:13

and

refit in the

following

order

the ball bolt,

nylon half bearing

shell, four

Belleville

washers

and the ball

head

cao.

4

Compress

the Belleville washers and

install

a

new

circlip

in the

gÍoove

above

the cap.

5 Position

the

ball head correctly with

the

pin

hole

in

the end of the ball bolt

at right angles to

the con-

necting

link axis. Lubricate the assembly.

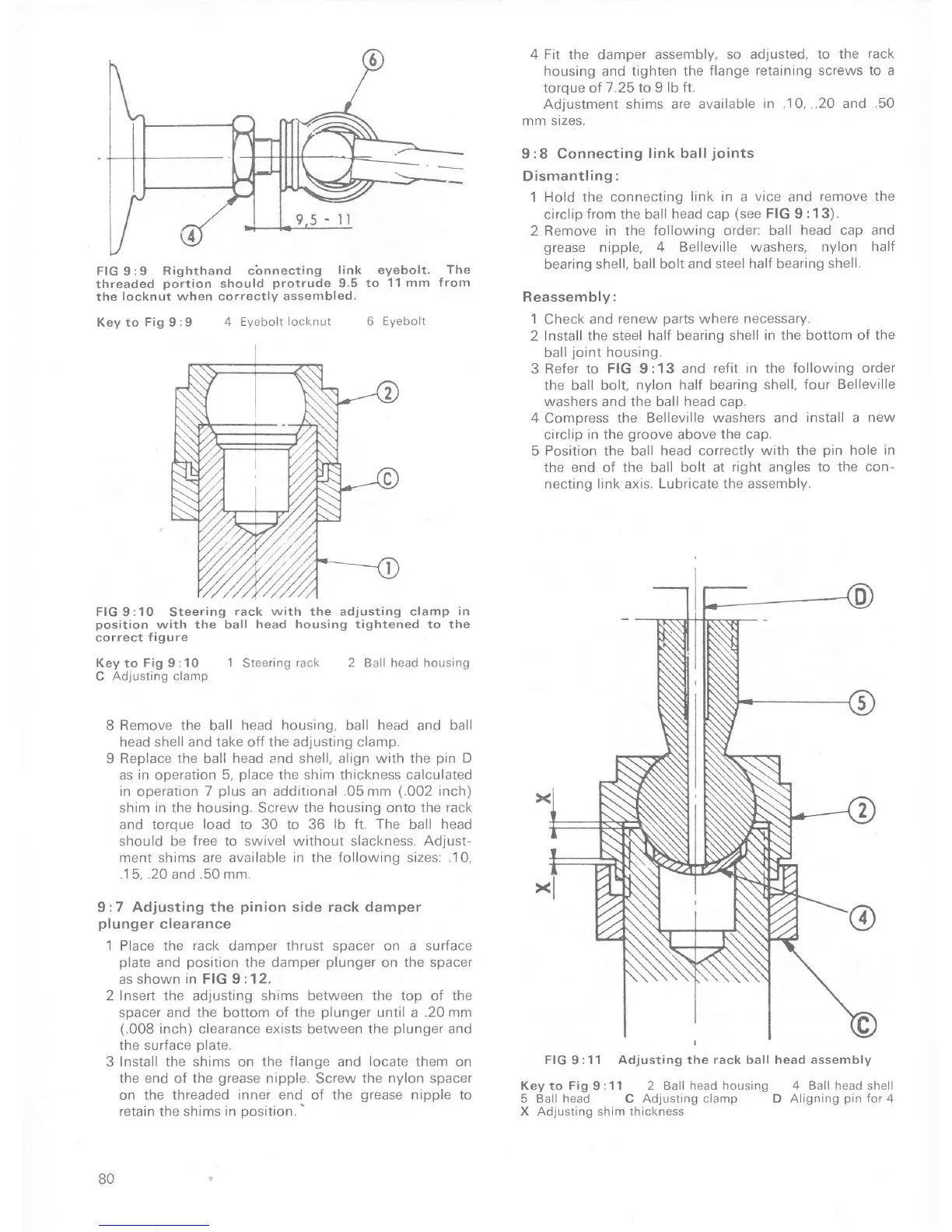

FIG 9 ;1 1 Adjusting the

rack

ball head assembly

Key to Fig 9:11 2

Ball head housing 4 Ball head shell

5

Ball head

C

Adjusting clamp

D

Aligning

pin

Íor 4

X

Adjusting

shim thickness

The

fro m

FIG

9:10 Steering

rack with

the adjusting clamp

in

position

with the ball head housing tightened to

the

correct

Íigure

Key to

Fig

9:10

1

Steering

rack

C

Adjusting clamp

2 Ball head housing

8

Remove the

ball

head housing, ball

head

and

ball

head shell

and

take oÍÍ

the

adjusting clamp.

9 Replace

the

ball

head and shell, align with the

pin

D

as in operation 5,

place

the shim thickness calculated

in

operation 7

plus

an

additional .05mm

(.002

inch)

shim in the housing.

Screw

the housing onto the

rack

and toroue

load

to 30 to 36

lb Í1.

The ball

head

should be free to swivel without slackness. Adjust-

ment shrms

are

available in the following sizes:

.10,

.15, .20

and

.50

mm.

9:7 Adjusting the

pinion

side

rack damper

plunger

clearance

'1

Place the Íack damper thrust spacer on a surface

plate

and

position

the damper

plunger

on the spacer

as shown

in FIG

9

:12.

2 Insert

the adjusting shims between

the top

of

the

spacer and

the

bottom

of the

plunger

until a .20 mm

(.008

inch)

clearance

exists

between

the

plunger

and

the surÍace Dlate.

3

Install the shims on the flange and

locate

them on

the

end

oÍ

the

grease

nipple. Screw

the

nylon spacer

on

the

threaded

inner end

of

the

grease

nipple to

retain

the shims

in

position.'

80

Loading...

Loading...