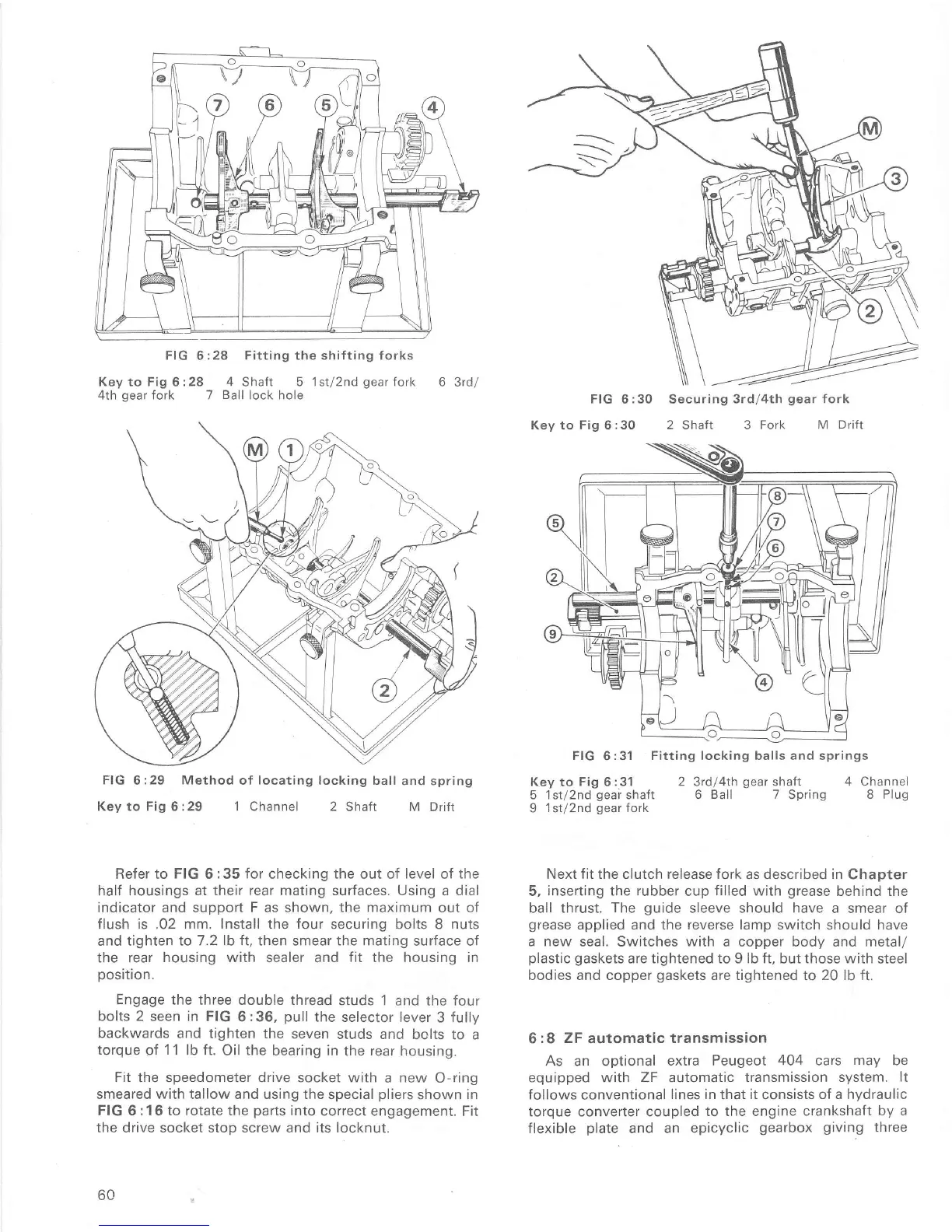

FIG 6 :28 Fitting the shiÍting forks

Key to Fig 6 :28 4 Shaft 5 1 st/2nd

gear

Íork

4th

gear

Íork 7

Ball

lock hole

6

3rd/

Key to Fig

6:29

1 Channel 2

Shafr M Drifi

Refer to

FIG

6:35

for

checking

the

out of

level

of

the

half housings at their Íear mating surfaces. Using a dial

indicator and support

F

as shown,

the maximum

out oÍ

flush is.02 mm.

Install the four

securing bolts 8

nuts

and tighten to 7 -2

lb ft,

then smear the mating surface of

the

rear housing with sealer and fit the housing in

position.

Engage the

three double thread

studs 1 and the Íour

bolts

2

seen in FIG

6:36,

pull

the selector lever

3 fully

backwards

and tighten the

seven studs and

bolts to a

torque

of

11

lb ft.

Oil

the

bearing in the rear

housing.

Fit

the speedometer drive socket with

a

new

O-ring

smeared with tallow and using the special

pliers

shown in

FIG 6:16 to rotate the

parts

into

correct engagement. Fit

the drive socket stop screw and its locknut.

60

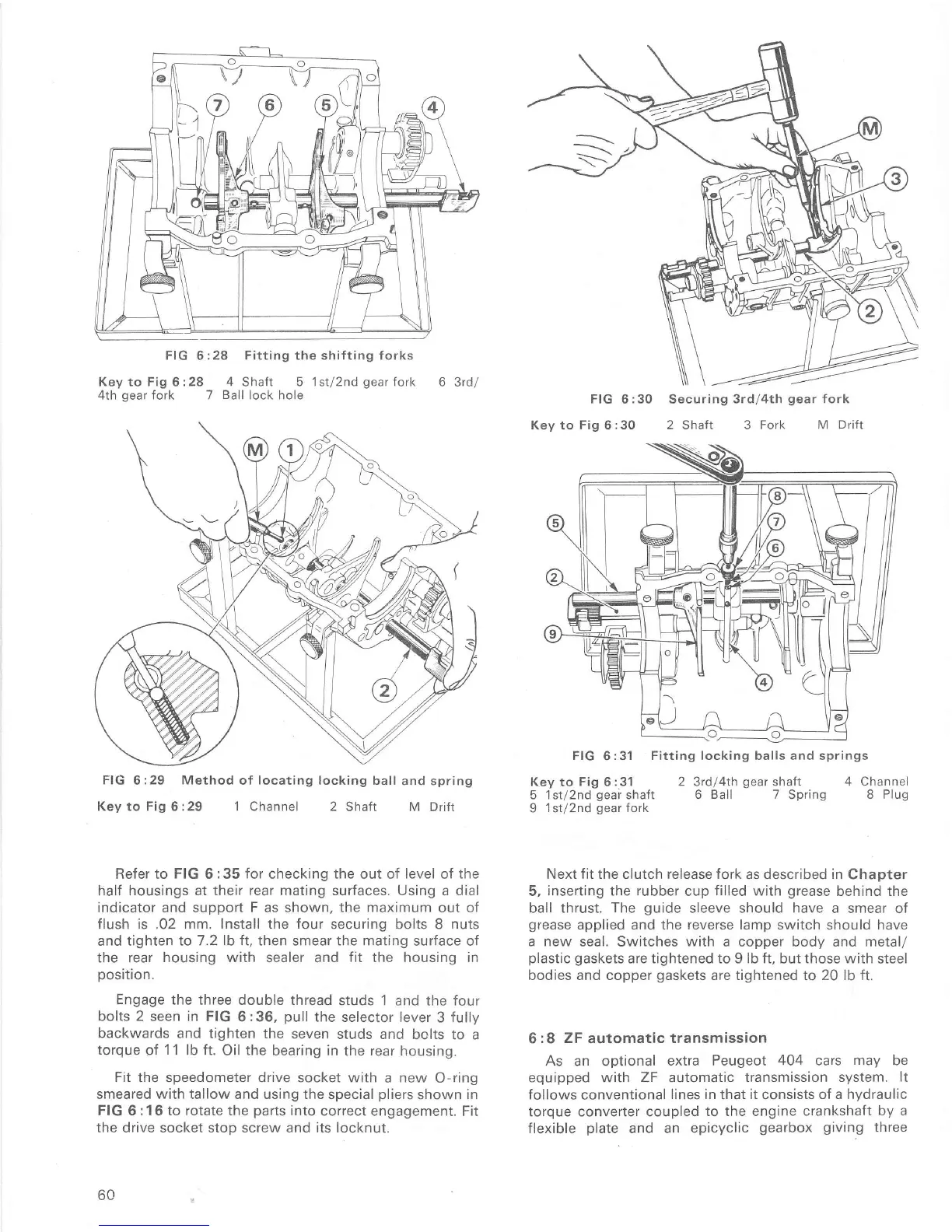

Key

to

Fig

6

:30 2 Shaft 3 Fork M

DriÍt

FIG 6:31 Fitting locking balls and springs

Key to

Fig

6:31

2 3tdl4th

geaí

shaft

4 Channel

5 lsrl2nd

gear

shaft 6

Ball 7

Spring

8 Plug

9

1st/2nd

gear

fork

Next fit the clutch release fork

as

described in

Chapter

5,

inserting

the

rubber

cup

filled

with

grease

behind the

ball thrust.

The

guide

sleeve should

have

a smear of

grease

applied and the reverse lamp switch

should

have

a new

seal. Switches

with

a copper body and metal/

plastic

gaskets

aÍe tightened to 9 lb ft, but those with

steel

bodies and copper

gaskets

are tightened to 20 lb ft.

6:8

ZF

automatic

transmission

As an optional extra

Peugeot

404

cars

may

be

equipped with ZF automatic transmission

system.

lt

follows conventional

lines in

that

it

consists

of a hydraulic

torque converter coupled

to the engine crankshaft

by a

flexible

plate

and an epicyclic

gearbox

giving

three

FIG

6:29

Method

oÍ

locating

locking ball

and spring

Loading...

Loading...