-@

,@

---g

/-@

21

20

l9

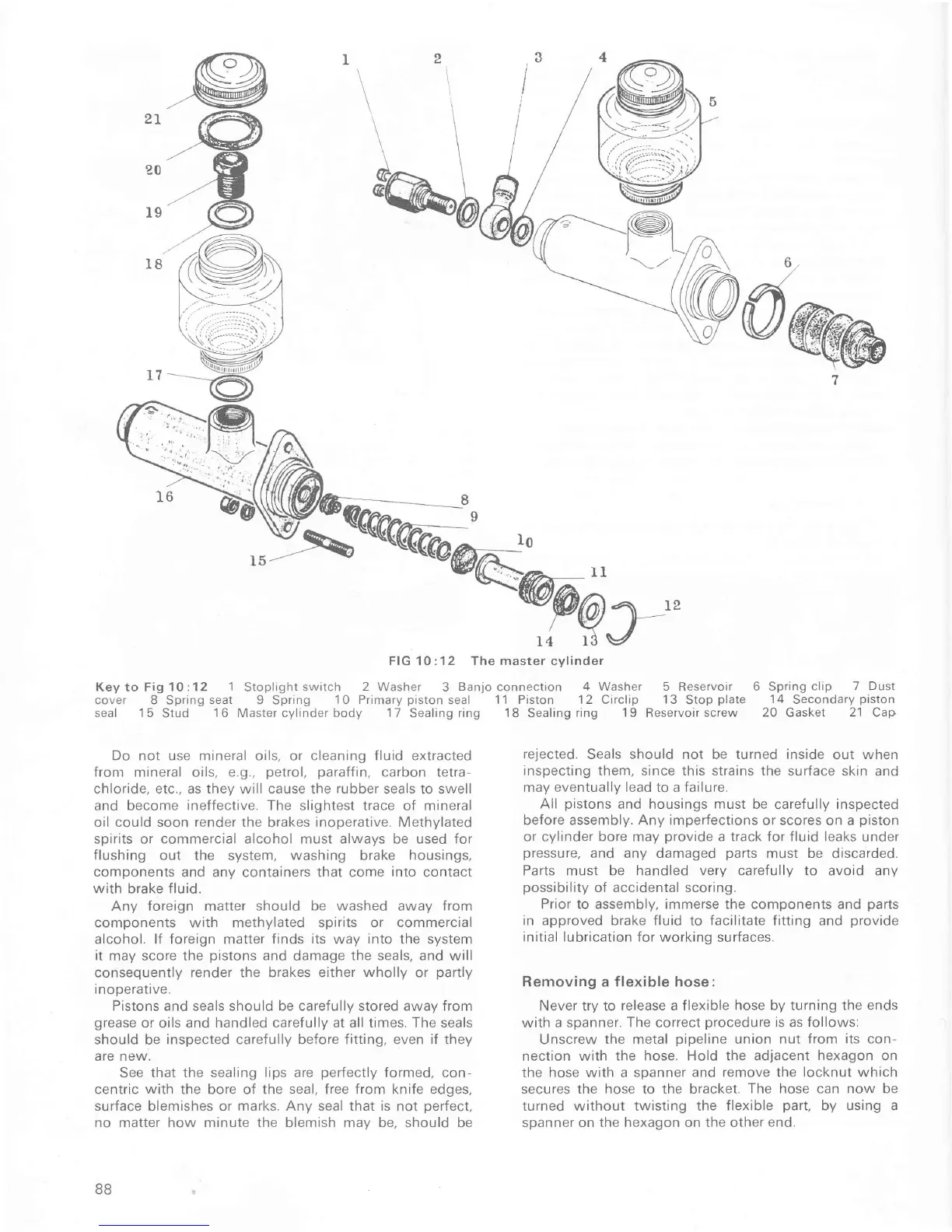

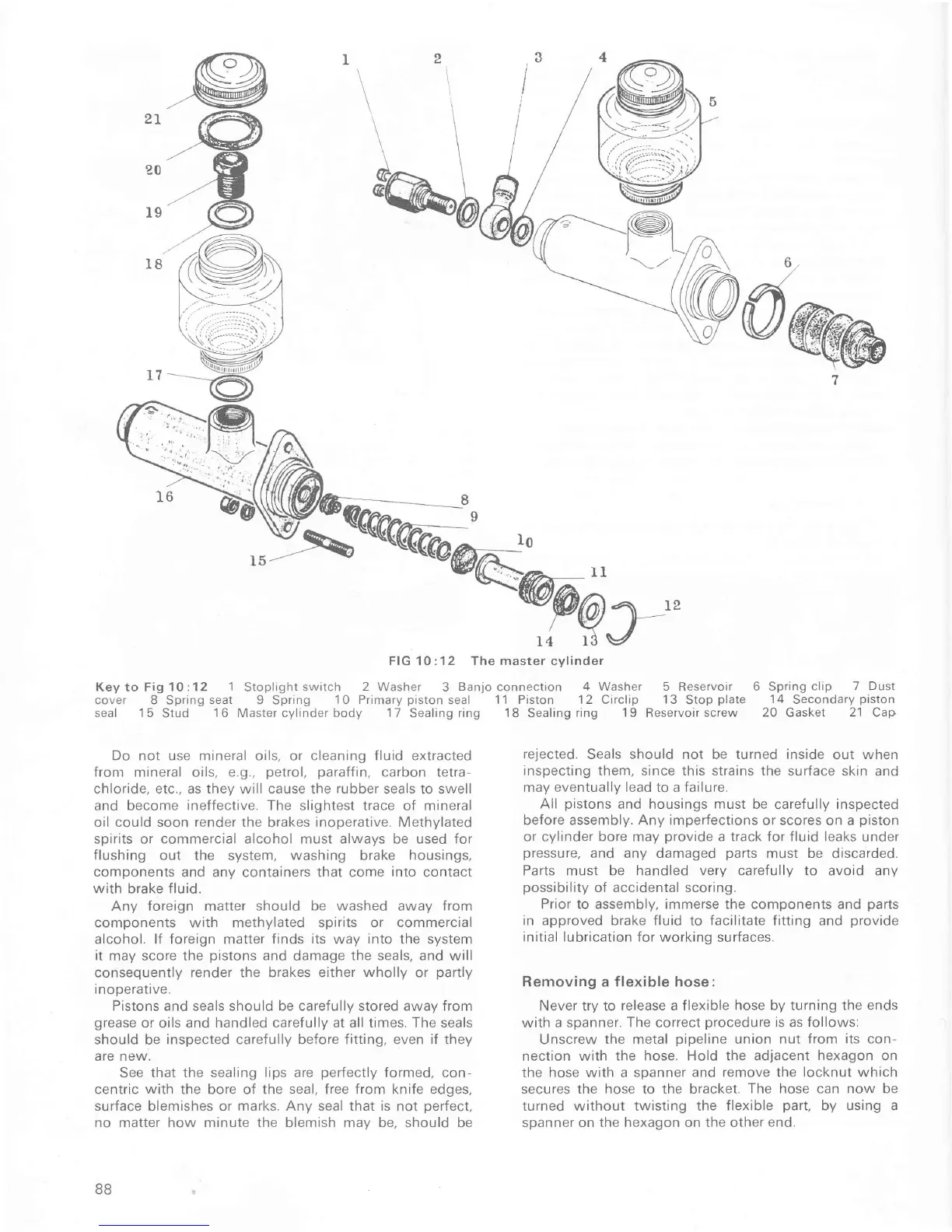

FIG

10:12

The

masteÍ

cylinder

KeytoFigl0:12

1

Stoplightswitch

2 Washer

3

Banjoconnection 4 Washer 5 Reservoir 6 Springclip

7 Dust

cover 8

Springseat

9 Spring

10 Primarypistonseal 1l Pislon 12 Circlip 13

Stopplate

14

Secondarypiston

seal 15

Stud

'16

Mastercylinderbody

17

Sealingring

18

Sealingring

19

Reservoirscrew

20 Gasket 21 Cap

Do not use mineral oils, or cleaning Íluid extracted

Íronr mineral

oils,

e.9.,

petrol, paraffin,

carbon tetra-

chloride, etc., as they will cause the

rubber

seals to swell

and

become ineffective, The slightest trace

of mineral

oil could soon render the brakes inoperative. Methylated

spirits

or

commercial alcohol must always

be

used for

ílushing

out the system,

washing

brake

housings,

components and any

containers

that come into contact

with brake Íluid.

Any

Íoreign

matter should

be washed

away

Írom

components with methylated

spirits

or commercial

alcohol. lf foreign matter finds

its

way

into

the system

it

may

score

the

pistons

and

damage

the seals, and

will

consequently render the brakes either

wholly

or

partly

inoperative.

Pistons and

seals

should be carefully stored

away

from

grease

or oils and handled carefully at all times. The seals

should be inspected careÍully

beÍore fitting, even iÍ

they

are new.

See

that the sealing lips are

perfectly

formed, con-

centÍic

with

the bore oí the

seal,

íree

from

knife

edges,

surÍace blemishes or marks. Any seal that is

not

perfect,

no matter how minute

the blemish

mav be. should be

88

re.jected.

Seals should not be turned inside

out

when

inspecting

them, since this strains the surÍace

skin and

mav

eventuallv lead to a failure.

All

pistons

and housings must be

carefully inspected

before assembly. Any imperfections

or

scores

on a

piston

or cylinder bore may

provide

a track for fluid leaks under

pressure,

and any damaged

parts

must be

discarded.

Parts must be handled

very

carefully to avoid any

possibility

of accidental scoring.

Prior to assembly, immerse the components

and

parts

in approved brake fluid

to

facilitate fitting and

provide

initial lubrication

for workino surÍaces.

Removing a flexible hose:

Never try to

release a flexible hose by turning the

ends

with a

spanneÍ. The correct

procedure

is as follows:

Unscrew

the metal

pipeline

union

nut from its con-

nection

with the hose. Hold the adjacent

hexagon on

the hose with a spanner and

remove the locknut which

secures the hose to the bracket.

The hose

can

now be

turned without twistrng the

flexible

part.

by using a

spanner on the hexagon on the other end.

Loading...

Loading...