For all cars built

prior

to

this modification

the corres-

ponding

dimensions are:

a

161

mm

(6.338

inches).

b 22 mm

(

.866

inches).

5:4

Removing the clutch

To remove the

clutch and transmission it is not neces-

sary

to remove the

engine but

the

rear axle and trans-

missron must be removed as Íollows:

1 Disconnect the battery.

2Install

the

engine support cross beam, No.8.01

16In

position

as shown

in

FIG 5:5.

Insert the

rod into the

suspension eyelet below

the

ignition coil and screw

rn a few turns to

support

the

engine.

3 Remove

the

clutch thrust bearing lubricating tube

and disconnect

the

thrust bearing linkage

and

return

spring.

4

Remove the clutch housing

plates

and

disconnect the

speedometer

cable.

5

Unscrew the two nuts from the

clamp securing the

exhaust

pipe

to the manifold,

as

well

as

the

nut

securing the

clamp

to the

rear

gearbox

housing.

6

Djsconnect the

gearchange

controls and the hand-

brake

cables

at

the

brake

equalizer

and

Íloor

connec-

trons.

7 Disconnect the hydraulic brake hose

from its attach-

menr lug and the flange securing the fuel

and

brake

l r nes,

8

Remove the rear engine

mounting

attaching

screws.

9

Disconnect the rear

shock absorbers at the axle tube.

and

the

stabilizer bar at

the lefthand

side.

10 Remove the screws securing the torque tube ball

joint,

jack

up the

rear

of the

car and

disconnect

the rear

springs.

11

Move

the rear axle

rearwards to

cleaÍ

the torque tube

at

the universal

joint

splines,

l2Support the

gearbox,

remove

the

clutch

housing

retaining scÍews, withdraw

the

gearbox

rearwards

and

remove from the

car.

13 Mark the clutch mechanism

in relation to the flvwheel

in order to facilitate correct

reassembly,

Slacken

each

of the six retaining bolts

approximately one

turn

at a

time,

working

diagonally across

the clutch, until

all

the

pressure

has been removed Írom the coil springs or

diaphragm,

5:5 Driven

plate

and

pressure plate

Inspect the

clutch disc and

pressure plate.

Check that

the

linings

are secure and free from

oil.

The disc

should

also

be checked for excessive wear

and signs of over-

heating. lf the linings

are

worn

down near to the rivet

heads, or. iÍ any of the

above

conditions

are

present,

the

disc should be renewed,

Check the condition

of

the

pressure

Dlate and the

release

plate

surface, Should any signs

of scoring,

overheatrng or distortion be

present,

change the assembly.

For inspection, removal and repair

of

the flywheel

see

Section

1 :9.

5:6 Refitting the

clutch

To refit the clutch

assembly, align the

marks

on the

flywheel

and

clutch cover made

during dismantling,

and

install the clutch assembly using

a

used clutch

shaft

to

align

the driven

plate

with the clutch

spigot.

P404

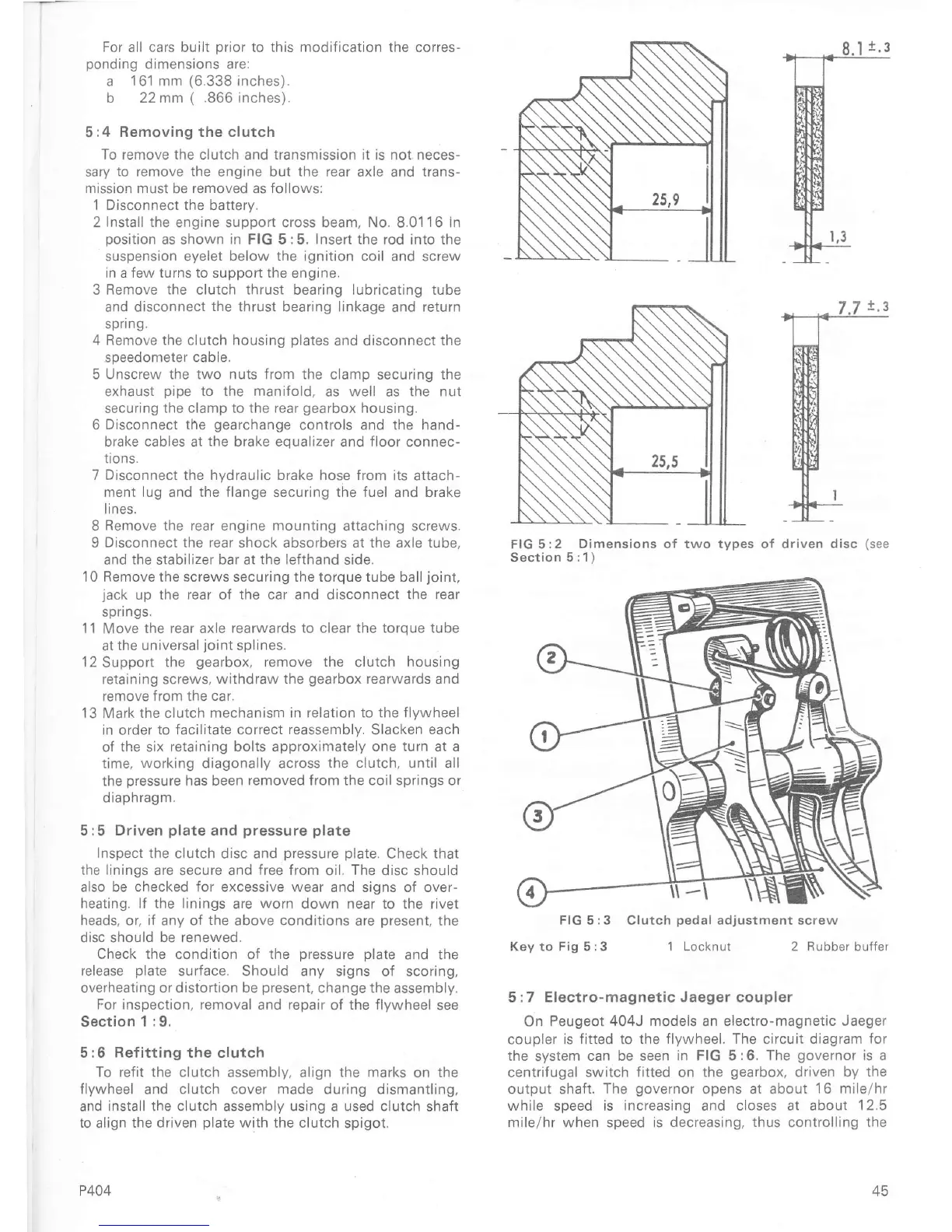

FIG

5:2 Dimensions

of

two types of driven

disc

(see

Section

5 :1)

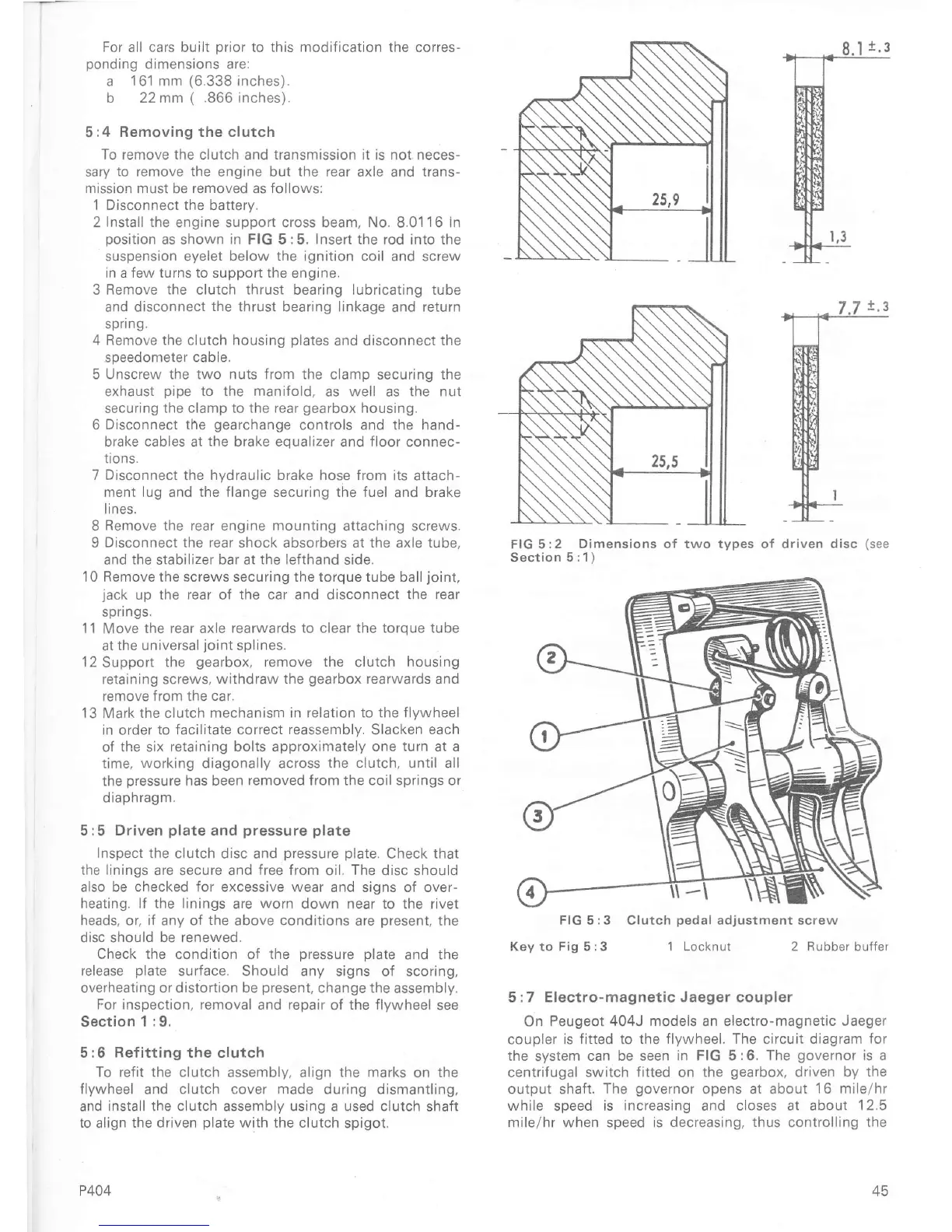

Key

to

Fig 5:3 1 Locknut 2 Rubber

buífer

5

:7 Electro-magnetic Jaeger coupler

On Peugeot

404J models

an

electro-magnetic Jaeger

coupler is

Íitted

to

the flywheel, The circuit diagram for

the

system

can be seen in

FIG

5:6.

The

governor

is a

centrifugal switch

fitted

on

the

gearbox,

driven by the

output shaft.

ïhe

governor

opens at about

16 mile/hr

while

speed

is increasing

and

closes at about

12.5

mile/hr when

speed

is decreasing, thus controlling the

FIG 5:3 Clutch

pedal

adjustment screw

Loading...

Loading...