lÍ the

spark

is weak

and

irregular,

check that the

lead

is not

perished

or cracked.

lí it

appears to be defective,

renew it

and

try another test.

lÍ

there is no improvement,

remove

the distributot cap and

wipe

the

ingide clean and

dry.

Examine the carbon button for wear and the seg-

ments Íor burning.

Inspect the caps for cracks

and

tracking burns.

Tracking

will

be

indicated

by a

thin

black

line

between

the

segments.

3:4

Timing

the

ignition

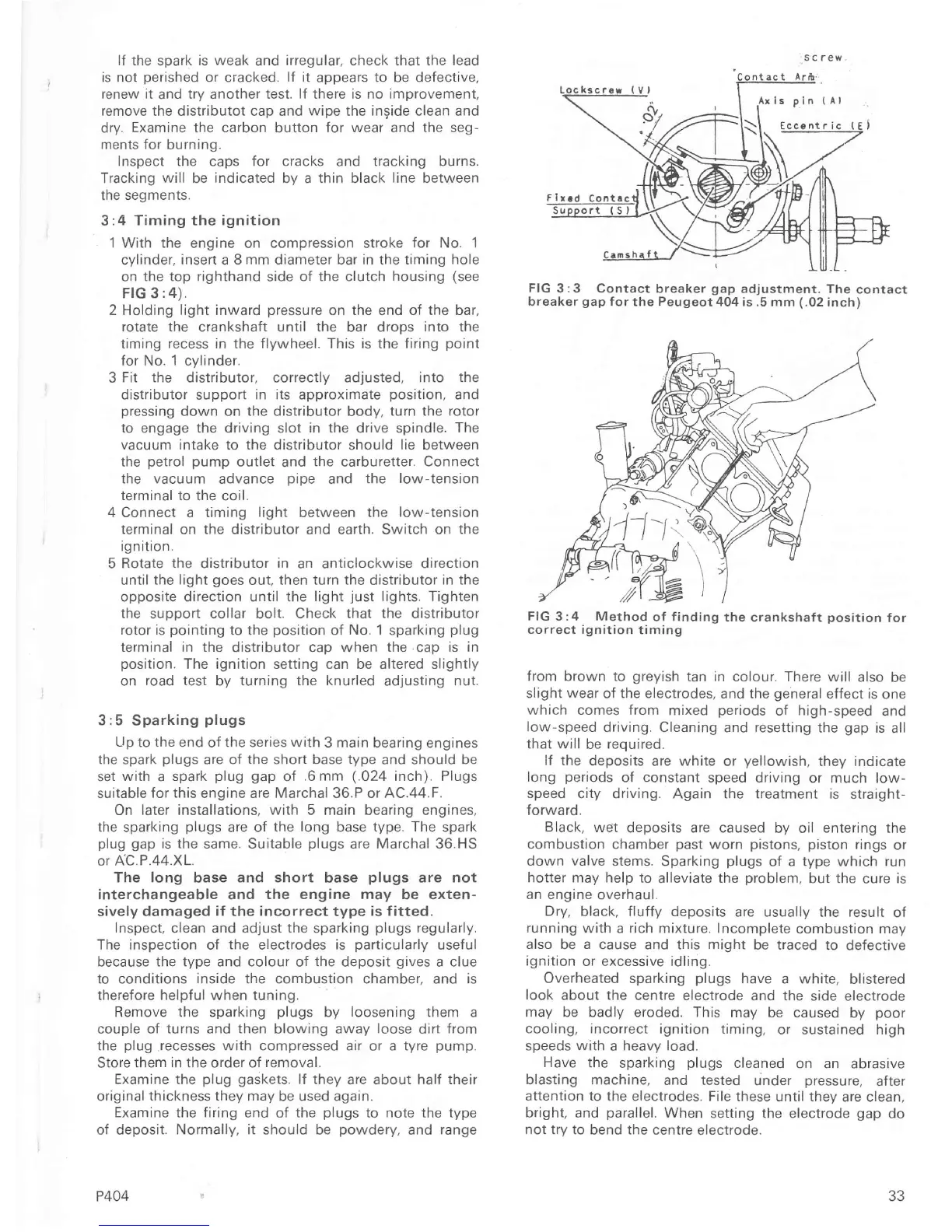

1 With the

engine on

compression stroke

Íor

No. 1

cylinder,

insert

a 8

mm diameter

bar

in

the

timing hole

on the top righthand side oÍ the clutch

housing

(see

FIG 3:4).

2 Holding

light

inward

pressure

on the

end

of the bar,

rotate the

crankshaft

until the

bar drops

into the

timing

recess

in the Ílywheel.

This

is the

firing

point

Íor No.

1

cvlinder.

3

Fit the

distributor,

correctly adjusted, into the

distÍibutor

support

in its approximate

position,

and

pressing

down on the distributoÍ

body,

turn the rotor

to engage the driving slot

in the

drive spindle.

The

vacuum intake to the distributor

should

lie

between

the

petrol pump

outlet

and

the carburetter. Connect

the vacuum advance

pipe

and

the low-tension

terminal to the

coil.

4 Connect

a

timing

light

between

the low-tension

terminal

on the distributor and earth. Switch on

the

ig

n ition,

5

Rotate the

distributor

in

an anticlockwise direction

until

the light

goes

out,

then turn the

distributor

in the

opposite direction until the

light

just

lights. Tighten

the

support

collar

bolt.

Check that the distributor

rotor is

pointing

to the

position

of

No. 1

sparking

plug

terminal in the

distributor

cap when the cap is in

position.

The

ignition

setting can be

altered

slightly

on

road test

by

turning the knurled

adjusting

nut.

3:5 Sparking

plugs

Up

to

the end

of

the

series

with

3

main

bearing engines

the spark

plugs

are of

the

short base

type

and should be

set

with

a

spark

plug gap

of

.6

mm

(.024

inch). Plugs

suitable for

this

engine are Marchal 36.P or 4C.44.F.

On later installations,

with 5

main bearing engines,

the sparking

plugs

are oÍ

the long

base

type. The

spark

plug gap

is the

same. Suitable

plugs

are Marchal 36.HS

or AC.P.44.XL,

The long

base

and short

base

plugs

are

not

interchangeable and the engine may be exten-

sively damaged

iÍ

the

incorrect

type

is f itted.

Inspect, clean

and adjust

the

sparking

plugs

regularly,

The inspection of the electrodes is

particularly

useÍul

because the type and colour of

the

deposit

gives

a clue

to conditions inside the combustion chamber, and is

therefore

helpÍul

when

tuning.

Remove the sparking

plugs

by

loosening

them

a

couple of

turns

and

then

blowing away

loose

dirt

from

the

plug

recesses with compressed air

or

a tyíe

pump.

Store

them rn the order of

removal.

Examine the

plug gaskets.

lf they

are about half

their

original

thickness they may

be

used

again.

Examine the firing

end of

the

plugs

to note

the

type

oÍ deposit.

Normally, it should be

powdery,

and

range

P404

screw

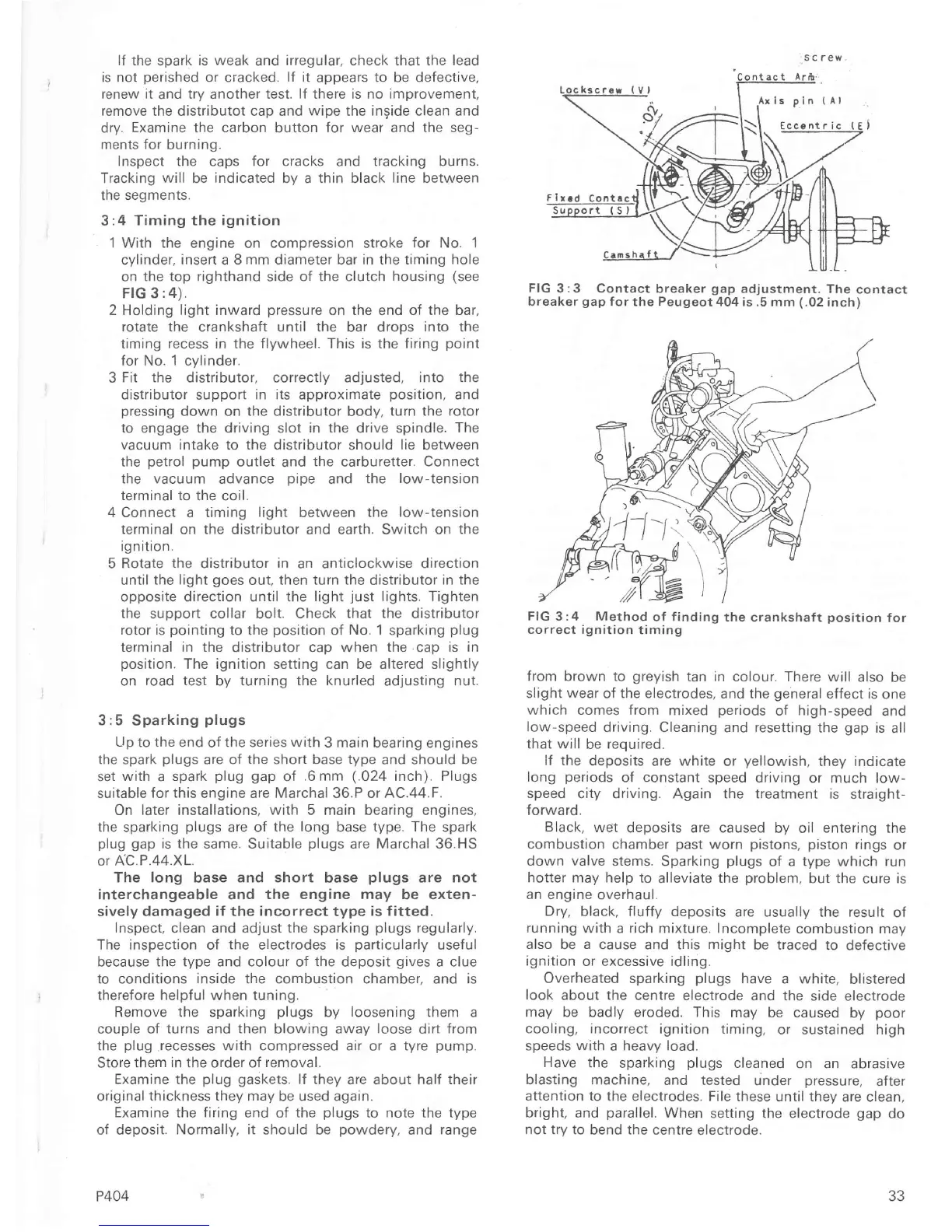

FIG 3:3 Contact

breaker

gap

adjustment. The

contact

breaker

gap

for the Peugeot 404 is

.5

mm

(.02

inch)

)

FIG

3:4 Mêthod

of finding

the crankshaft

position

for

correct ignition

timing

from

brown to

greyish

tan in colour. There will

also

be

slight

wear

of the electrodes,

and the

general

effect is

one

which comes from

mixed

periods

of high-speed

and

low-speed

driving. Cleaning

and

resetting

the

gap

is

all

that will

be

reouired.

lÍ the deposits

are

white

or

yellowish,

they indicate

long

periods

oÍ constant

speed driving or much low-

speed

city driving. Again the treatment is

straight-

forward.

Black,

wet

deposits are caused

by oil

entering

the

combustion

chamber

past

woÍn

pistons, piston

rings

or

down valve

stems. Sparking

plugs

of a type

which

run

hotter may help

to

alleviate

the

problem,

but the

cure

is

an engine overhaul.

Dry,

black, fluffy deposits

are usually the result

of

running

with

a

rich mixture. Incomplete

combustion

may

also be a cause

and this

might

be traced

to

defective

ignition

or excessive idling.

Overheated sparking

plugs

have

a white,

blisteÍed

look

about

the

centre electrode

and

the

side

electrode

may be badly eroded. This

may be caused

by

poor

cooling, incorrect

ignition timing,

or sustained high

speeds with

a

heavy load.

Have

the

sparking

plugs

cleaned

on an abrasive

blasting machine,

and tested

under

pressure,

after

attention to the

electrodes. File these until they

are clean,

bright, and

parallel,

When

setting the electrode

gap

do

not try to bend the

centre electrode.

l<.

11

/l

33

Loading...

Loading...