tighten

to a torque oÍ 7.2

lb ft. The lst/2nd

gear

fork I

must be secured

with

a

new locking

pin.

Before

refitting the

gear

assembly

the clutch

housing

must be checked

Íor the

parallelism

oÍ

its Íront

and

rear

faces.

This is done by laying it on a

flat

surface and using

a dial

gauge

as

shown in FIG

6

:32. ïhe housing must be

renewed of the

faces

are out of

parallel

by more than .

1

mm.

Install the

gear

assembly into the

lefthand

housing

as shown in

FIG

6:33, taking caÍe to see that the striking

Íorks are corÍectly engaged with the synchronizer rings.

Fit the outer

race for the intermediate

gearshaft

front

bearing

if it was removed, then apply a

thin

coat of sealer

to the mating faces of the halÍ

housings

and

fit them

together,

lnsert the four housing bolts shown at 4 in FIG 6:34

and tighten

them to a torque of 3.6 lb ft.

Smear

the

rear

Íace of the clutch housing with sealer and secure with

six bolts

tightened to 20 lb Ít. Secure the reaÍ backing

plate

with Íour Allen screws tightened to

7.2

lb

Ít.

Now slacken ofÍ

the Íour housing bolts

and

tap the

housrng

halves with

a

mallet while rotating the drive

shaÍt.

Finally retighten the four bolts to a torque of

11 lbÍr.

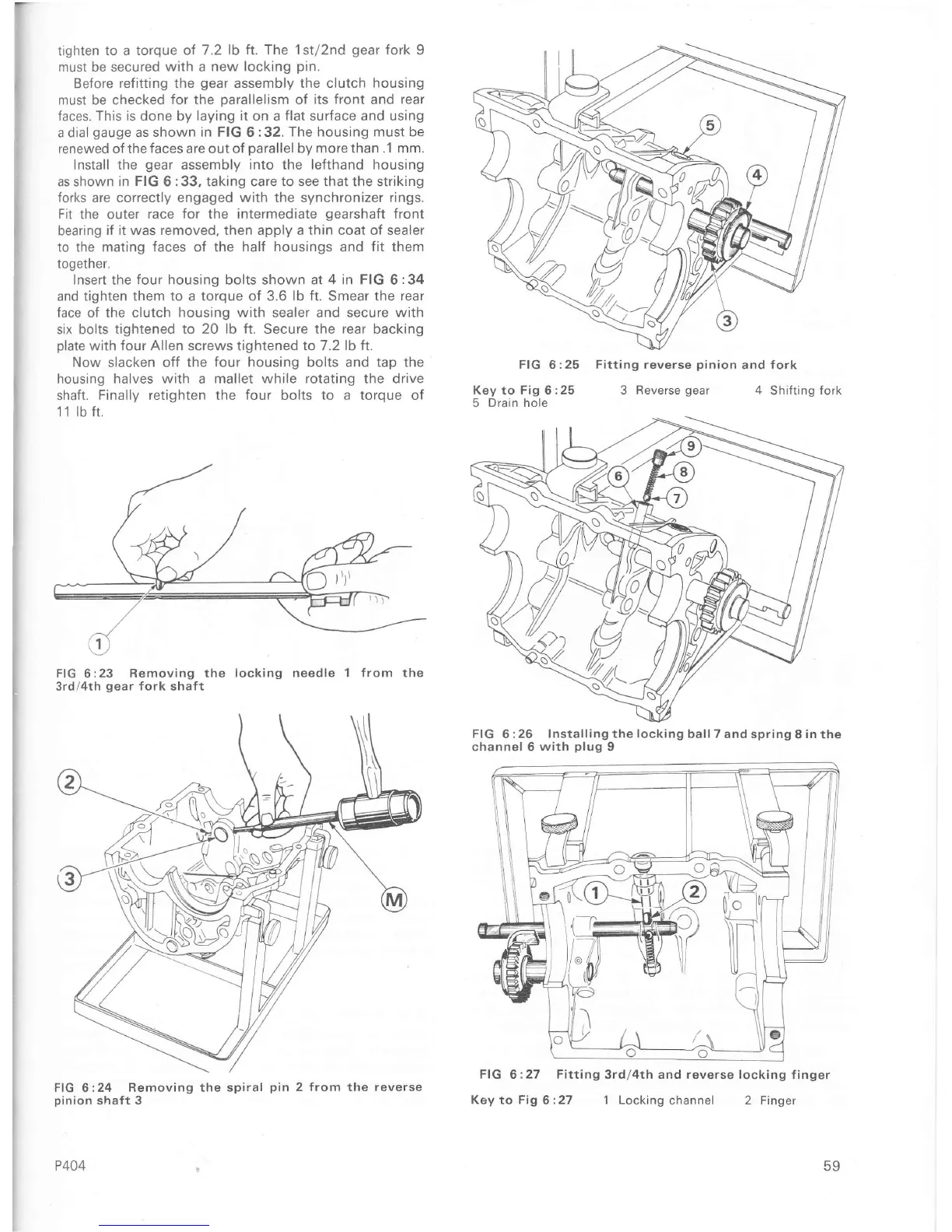

FIG 6:23

Removing the

locking needle 1 from the

3rd/4th

gear

Íork shaft

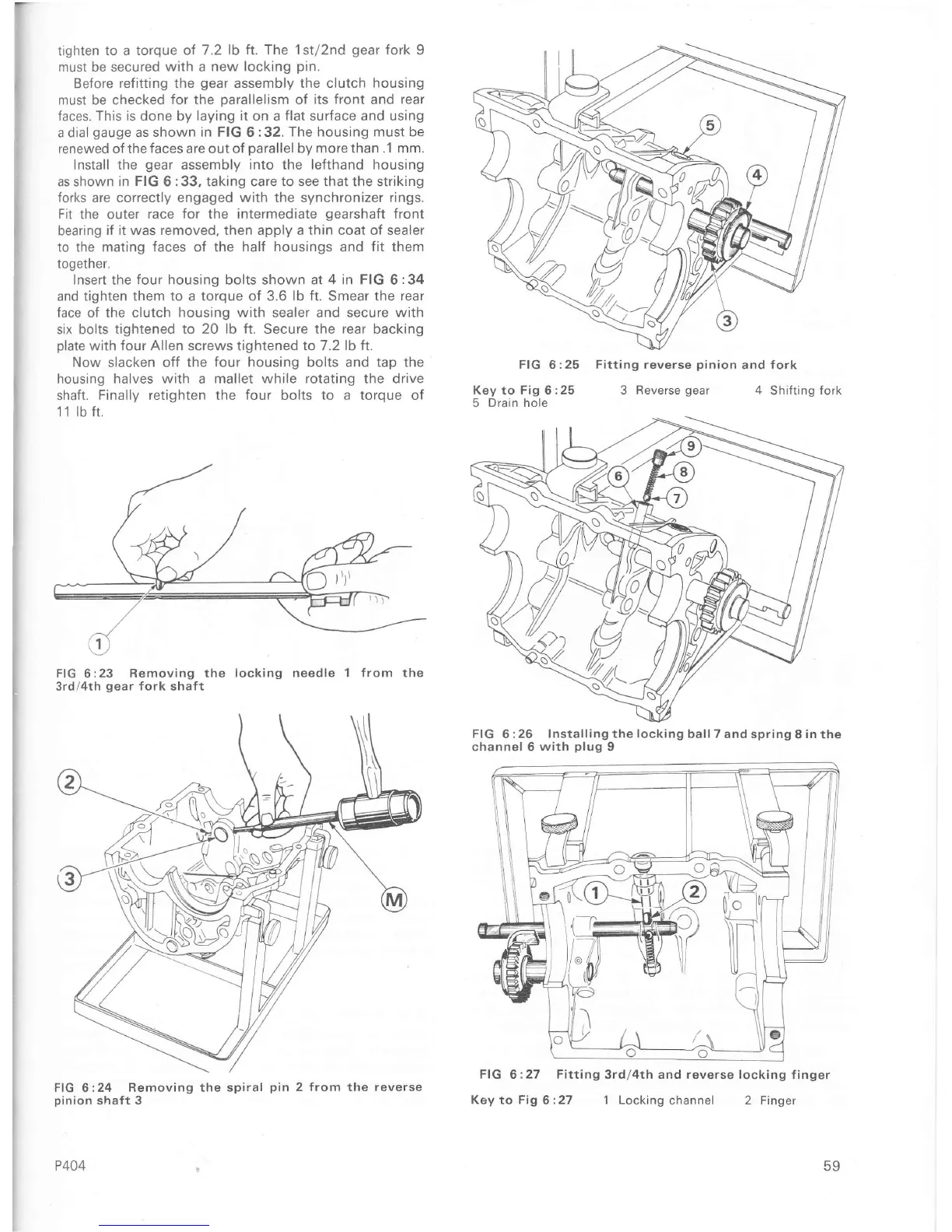

FIG

6:24

Removing the spiral

pin

2 from the raverse

pinion

shaÍt 3

P404

3

Beverse

gear

4 Shifting fork

FIG 6:26

InstallingthelockingballTandspringSinthe

channel 6

with

plug

9

Kêy to

Fig

6

:25

5

Drain hole

FIG 6:25 Fitting reverse

pinion

and

fork

FIG 6:27

Fitting

3rd/4th and reverse locking

finger

Key

to

Fig

6:27

1

Locking channel 2 Finger

qo

Loading...

Loading...