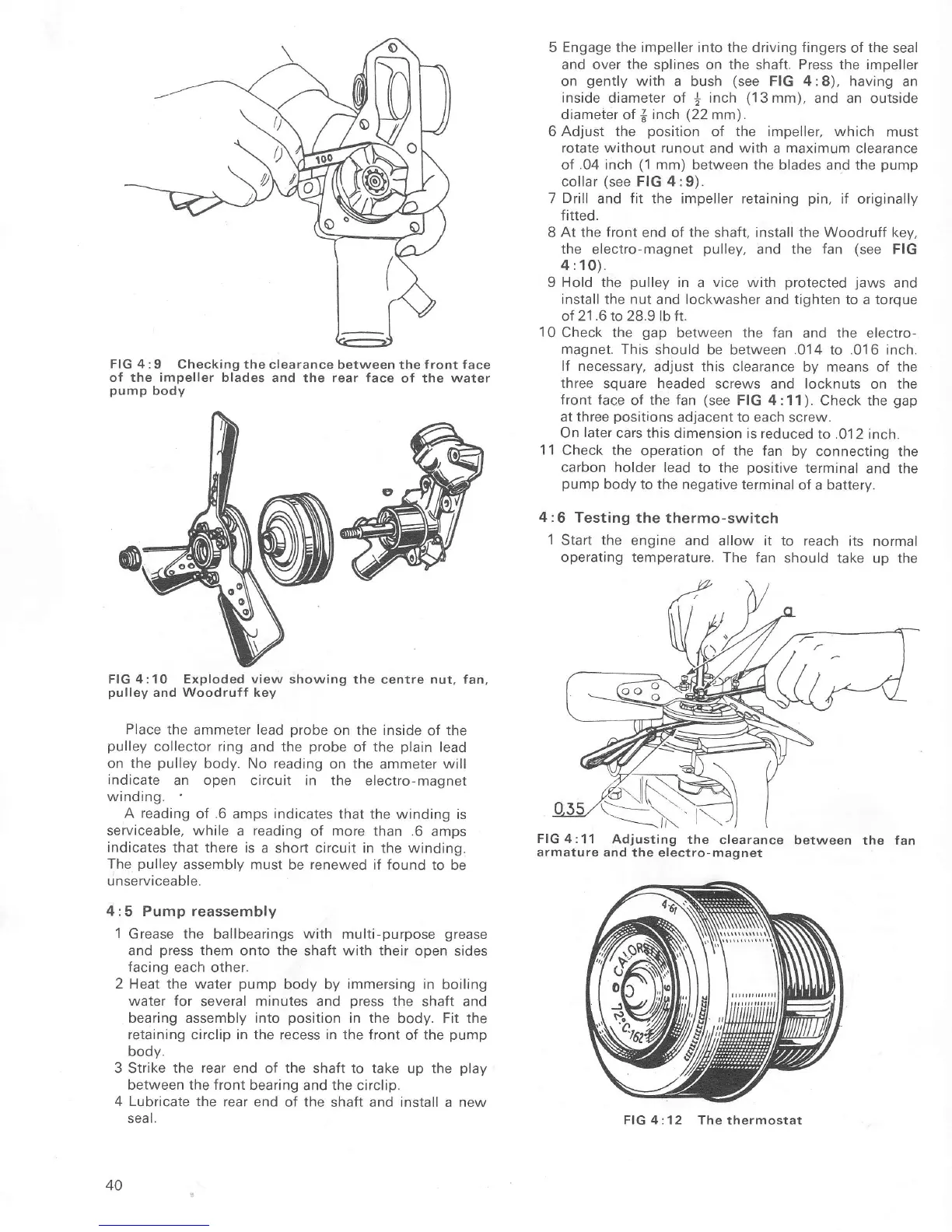

FIG 4:9

Checking the clearance

between the

front

face

of the impêller blades

and the rear face

of the

water

pump

body

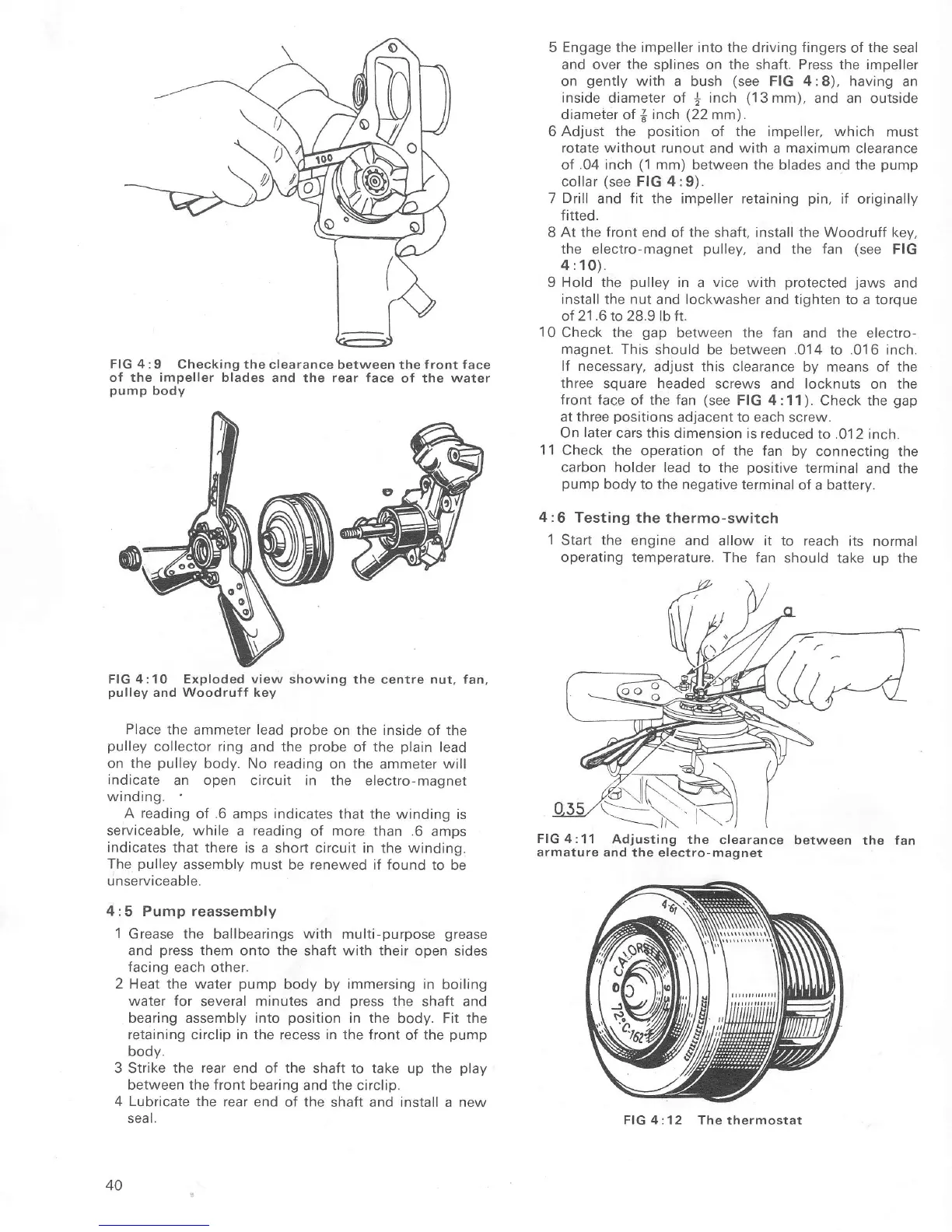

FIG

4:10 Exploded view showing

the centre nut, fan

pulley

and Woodruff key

Place

the ammeteÍ lead

probe

on the inside

of the

pulley

collector ring

and the

probe

oÍ

the

plain

lead

on the

pulley

body. No reading

on the

ammeter

will

indicate

an open circuit in the

electro-magnet

winding.

A

reading

of

.6

amps indicates that the winding

is

serviceable, while

a

reading

of

more

than .6

amps

rndicates

that there is

a short circuit in the winding.

The

pulley

assembly must be renewed if Íound

to be

unserviceable.

4:5 Pump reassembly

l Grease the

ballbearings

with

multi-purpose

grease

and

press

them

onto

the

shaft with their open

sides

facing

each other.

2 Heat the water

pump

body by

immersing

in boiling

water for

several minutes and oress the shaÍt and

bearing assembly into

position

in the

body.

Fit

the

retaining circlip in the recess in the

front of the

pump

body.

3 Strike the

Íear

end oÍ the shaft to take

up the

play

between the front

bearing and the circlip.

4 Lubricate

the rear end

of

the

shaÍt and install a new

sea

l.

40

5 Engage the impeller into the driving fingers

of

the

seal

and over the splines on the

shaft.

Press the impeller

on

gently

with a bush

(see

FIG 4:8), having

an

inside diameter

of

j

inch

(13

mm), and an outside

drameter of

{

inch

(22

mm)

.

6 Adjust the

position

of

the impeller, which

must

rotate without runout

and

with

a

maximum

clearance

of

.04

inch

(1

mm)

between the blades and the

pump

collar

(see

FIG 4:9).

7

Drill

and fit the impeller retaining

pin,

if originally

fitted.

8

At the front

end of

the

shaft, install the

Woodruff

kev,

the

electro-magnet

pulley,

and the

fan

(see

FIG

4:10).

9 Hold the

pulley

in

a

vice with

protected

jaws

and

install

the nut and lockwasher and tighten to a torque

of 21

.6

to 28.9 lb fr.

10

Check the

gap

between the Ían

and the electro-

magnet. This

should be

between

.014

to

.016 inch.

lÍ necessary,

adjust this cleaÍance

by means of the

three

square

headed

screws

and

locknuts

on the

front Íace

oÍ the fan

(see

FIG 4:11

).

Check the

gap

at three

positions

adjacent to

each screw.

On

later

cars this dimension

is reduced

to .0'1

2 inch

1 1

Check the

operation of the fan by

connecting the

carbon holder

lead to

the

positive

terminal

and the

pump

body to

the negative terminal

of a battery.

4:6

Testing

the thermo-switch

1

Start

the

engine and

allow it to reach its

normal

operating temperature.

The fan

should take up the

FlG4:11

Adjusting

the

clearance between

the

armature

and the electro-magnet

fan

FIG 4:12 The

thermostat

Loading...

Loading...