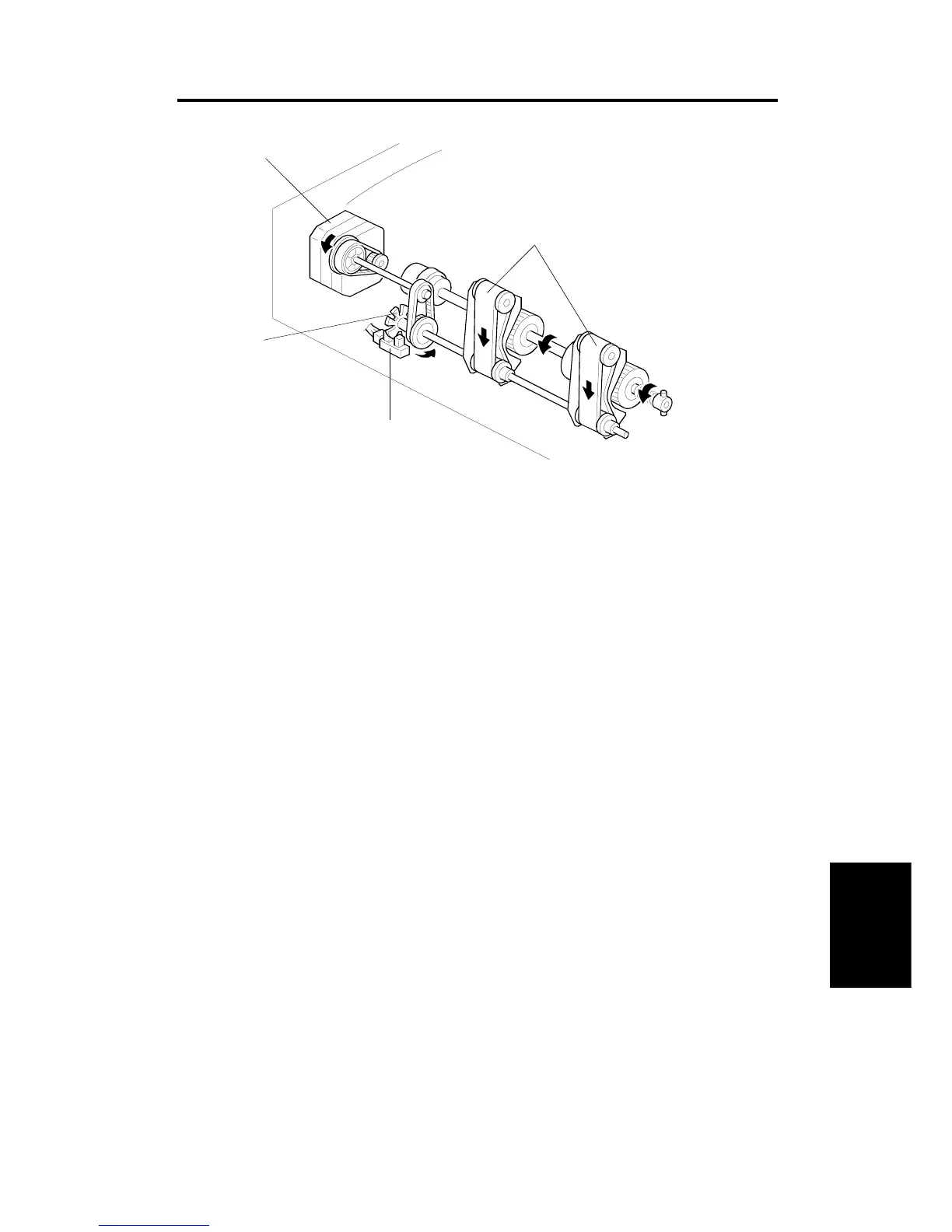

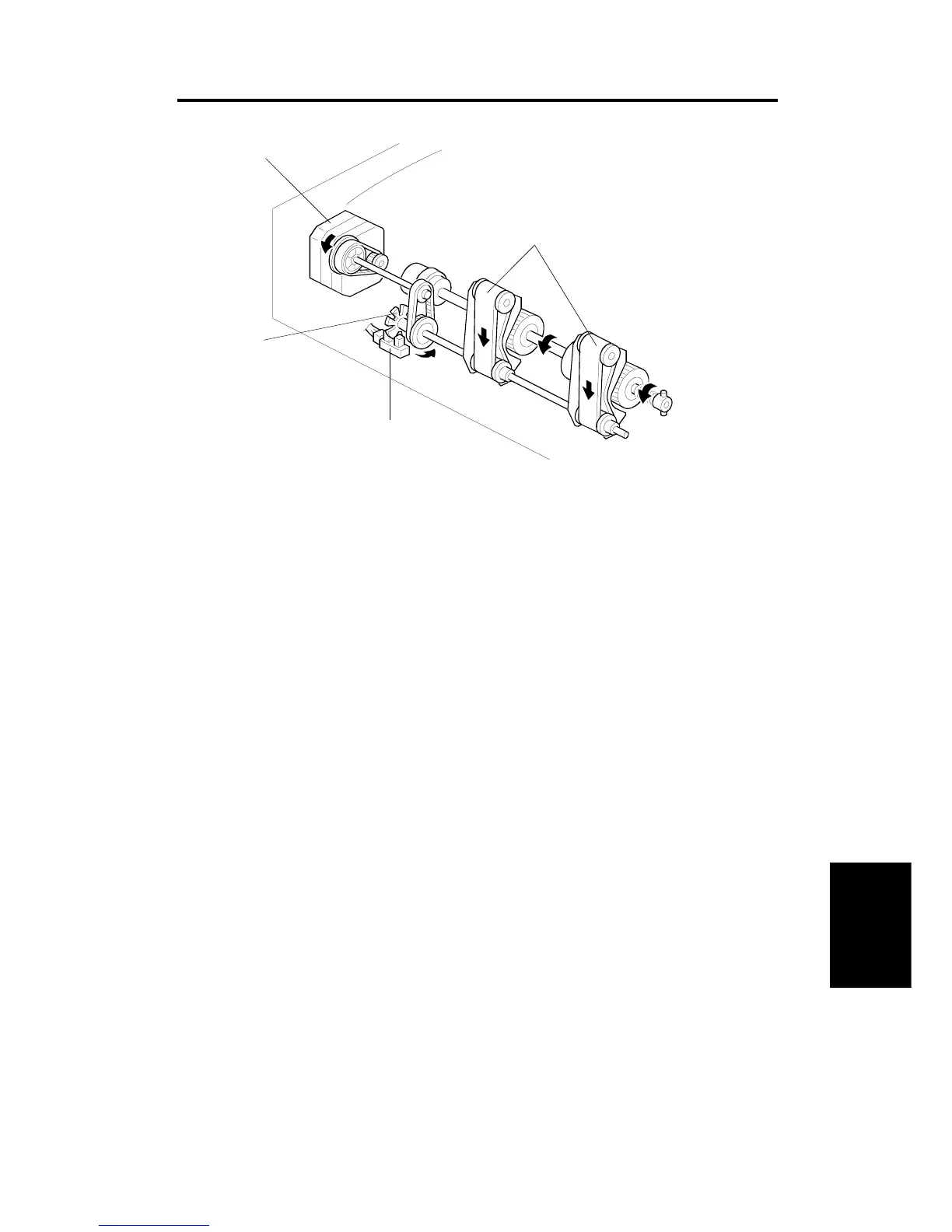

6. FRICTION BELT DRIVE MECHANISM

The friction belts [A] are driven by the friction belt drive motor [B] through

timing belts, as shown.

When the Start key is pressed, the friction belts are not rotated (the motor is

electrically ON but the motor does not turn as the voltage is too low; see the

timing chart in section 13.1). As the leading edge of the original activates the

registration sensor-2, the friction belts rotate in the reverse direction to

reverse out the next original from in between the friction belts and feed

rollers. This results in less of a chance for originals to be damaged or

become dirty. Also, the area of the friction belt that contacts the feed roller or

the original changes, to prevent multiple feeding.

The friction belt turn sensor [C] counts the pulses generated by the pulse

generator disk [D] on the friction belt shaft. The sensor detects friction belt

motor error conditions.

[A]

[B]

[C]

[D]

Dual Job Feeder

DF62 (A610)

SM 7-9 A172/A199

Loading...

Loading...