3.2 DRUM CHARGE CORONA WIRE/GRID CLEANING

The flow of air around the charge corona unit may deposit toner particles

and paper dust on the corona wire or corona grid plate. These particles may

interfere with charging and cause uneven charge on the drum.

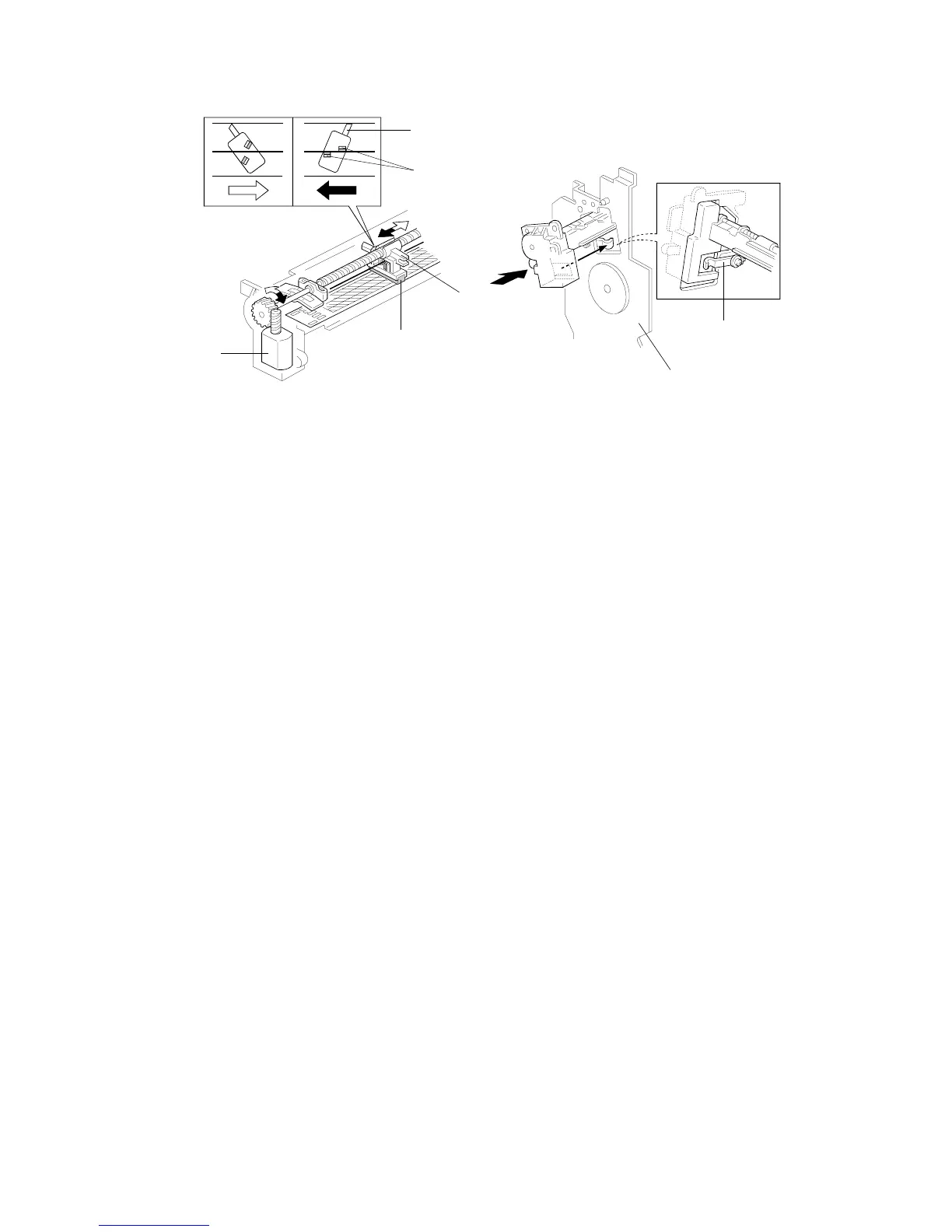

The wire cleaner [A], which consists of the wire cleaner pads [B] and the grid

plate sponge [C], automatically cleans the wire and the inside of the grid

plate to prevent such problems from appearing.

The wire cleaner is driven by a dc motor. Normally the cleaner is located at

the front end (this is home position). Whenever the main switch is turned on

while the hot roller temperature is below 80

°

C (before process control), the

wire cleaner motor [D] turns on to bring the wire cleaner to the rear end of

the corona unit and back to the home position. The corona wire and the

inside of the grid plate are cleaned at the same time. This procedure can be

manually performed with an SP mode as well (<2> SP Test, page 4).

When the cleaner moves from the home position to the rear position (the

white arrow in the illustration), only the grid plate is cleaned since the grid

plate sponge is always in contact. When coming back, the rib [E] on the

cleaner is forced by the opening in the corona casing, and the wire cleaner

pads contact the corona wire.

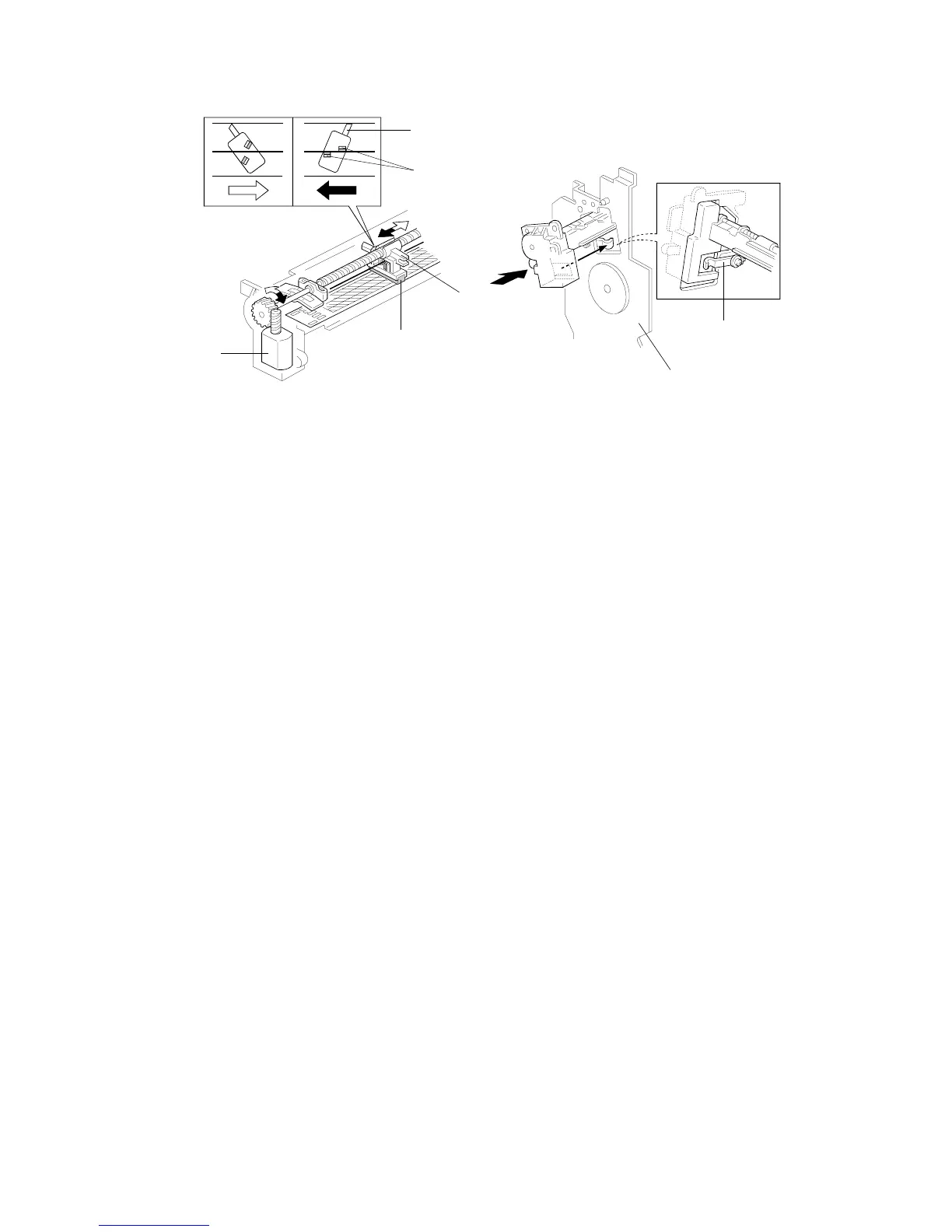

There are no home position or return position sensors. The wire cleaner

drive board at the back of the machine monitors the current applied to the

motor. When the wire cleaner reaches the end, it is stopped and the motor is

locked. At this time, the current of the motor slightly increases and the drive

board detects that it is time to rotate the motor in reverse.

Also, a grounding plate [F] is installed on the back side of the drum stay [G]

to reduce the electrical noise generated from the cleaner motor.

[A]

[C]

[D]

[B]

[E]

[G]

[F]

A172/A199 2-10 SM

Loading...

Loading...