9.4 OXYMAT 7 / ULTRAMAT 7: Introduction of reference gas

9.4.1 Selection of the reference gas

9.4.1.1 OXYMAT 7

Note

Composition of the reference gas

Using an unsuitable reference gas can cause the reference gas throttle (capillary tube) to be

closed. The device is then no longer capable of measuring.

Therefore, use dust-free reference gas or a standard dust lter with a mean pore width of <5 µm

in the reference gas inlet.

Overview

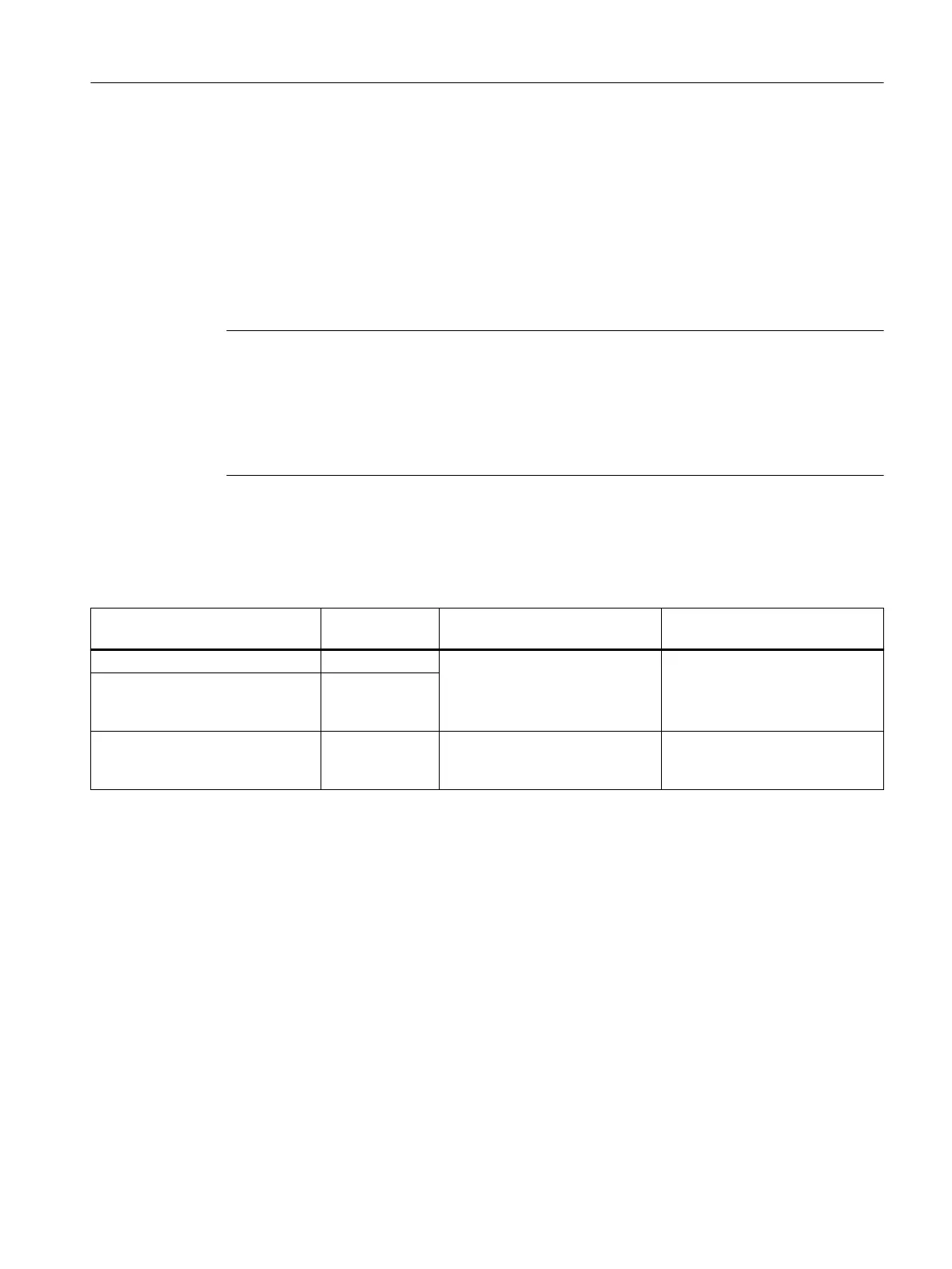

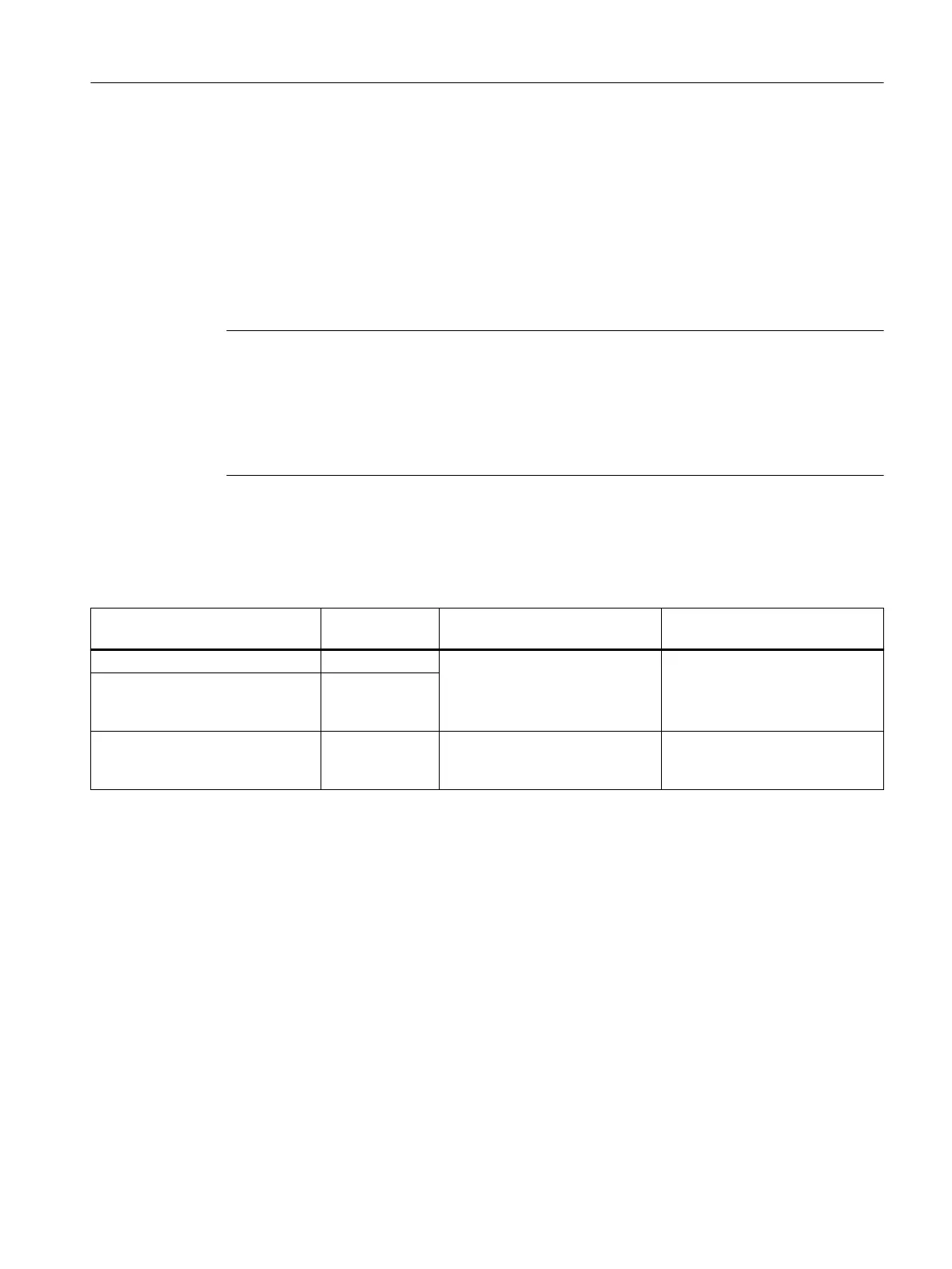

Table 9-1 Overview of the reference gases

Measuring range Recommended

reference gas

Reference gas connection pres‐

sure range

Comment

0to vol. % O

2

N

2

2 000 to 4 000 hPa above sample

gas pressure

(max. 5000hPa absolute)

The reference gas ow is set au‐

tomatically to between

5and12ml/min.

to 100 Vol. % O

2

(suppressed zero

point with full-scale value

100Vol.% O

2

)

O

2

0 ≤ 21 ≤ 100% O

2

(suppressed zero

with 21Vol.% O

2

within the span)

Air 100 - 150hPa with respect to

sample gas pressure

The sample gas pressure may uc‐

tuate by max. 50 hPa around the

ambient pressure

Reference gas "Air"

Air only has a constant O

2

share if the humidity is constant. Therefore use dry air.

For measurements with measuring ranges of 2%, the exact O

2

share of the reference gas

"Air" must be known. Use this value as the setpoint for a zero point calibration.

Selection of the reference gas

The various measuring spans must have at least one common value. This value is then dened

as the "physical zero point" and applies to all the measuring ranges. The reference gas can be

selected on the basis of the "physical zero point".

Commissioning

9.4OXYMAT 7 / ULTRAMAT 7: Introduction of reference gas

Wall-mounted device

Operating Instructions, 07/2023, A5E31930403-AB 127

Loading...

Loading...