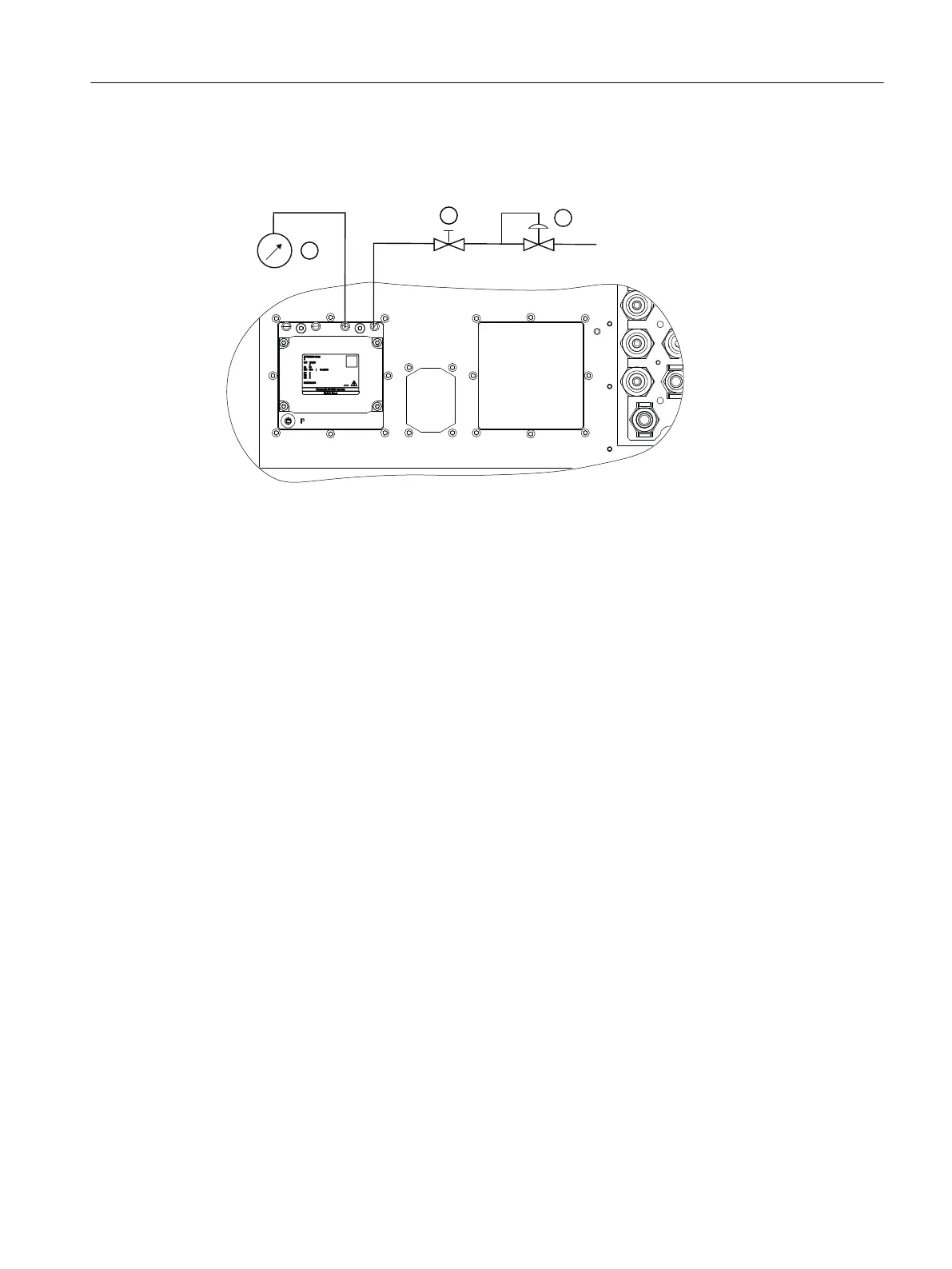

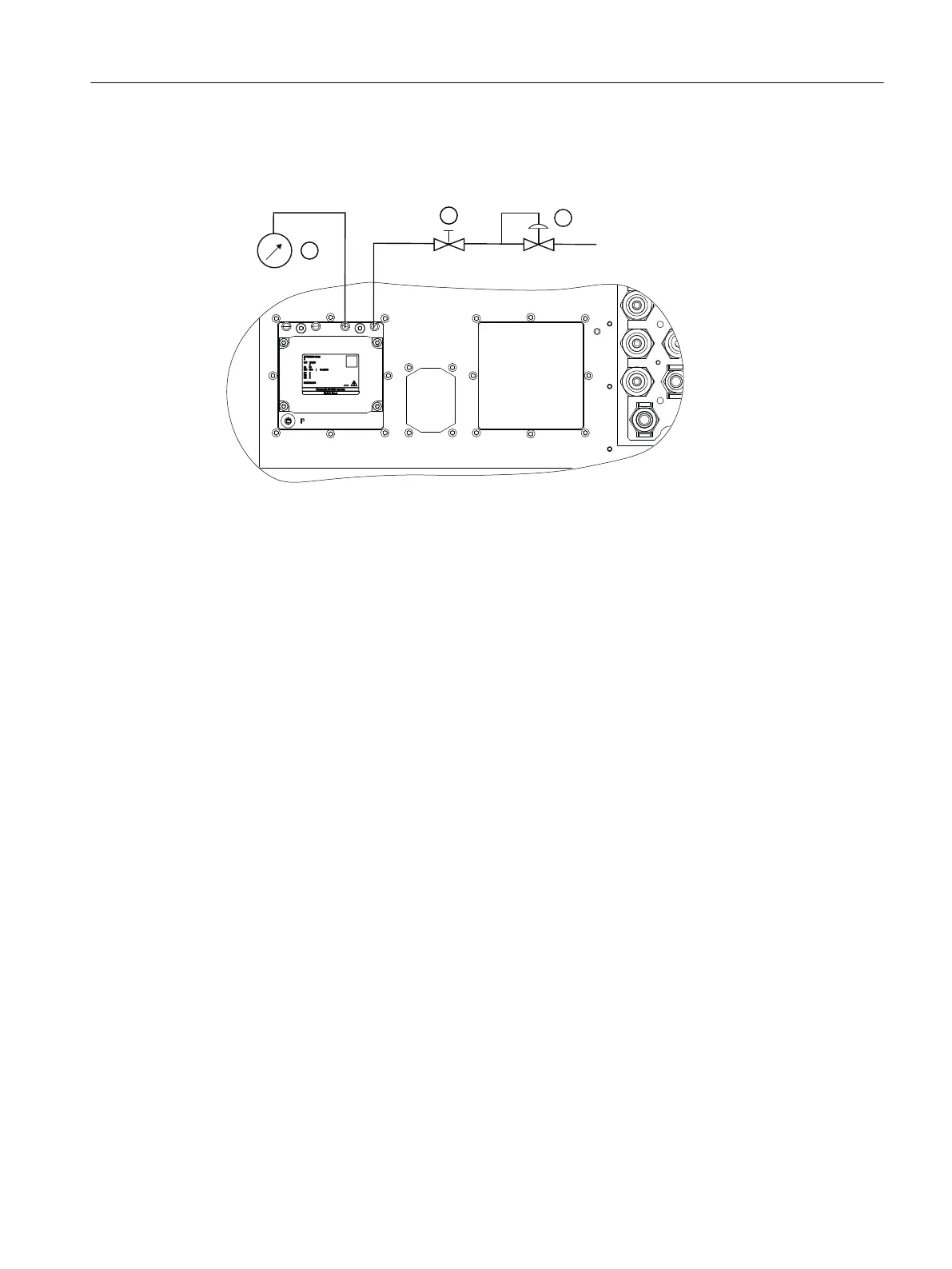

Test setup for leakage test with ULTRAMAT 7 high-temperature

To check for leaks, we recommend the following test setup:

① Shut-o valve

② Pressure regulator

③ Manometer (gauge pressure)

1 Sample gas inlet

2 Sample gas outlet

3 Unscrewing blanking plugs

4 Unscrewing blanking plugs

Figure9-6 Recommended test setup for leakage test with ULTRAMAT 7 high-temperature

9.6.5 Checking OXYMAT 7 for leaks

Procedure: Devices with pipes

1. Close the reference gas inlet.

2. Connect a pressure measuring instrument (manometer) to the sample gas outlet.

3. Carefully apply pressure of approximately 3000 hPa (absolute pressure) to the measuring

inlet.

4. Then shut o the measuring inlet.

5. Wait for approximately 5 minutes until the test gas that owed in has reached the ambient

temperature and the pressure remains stable.

Note the pressure.

6. Wait an additional 5 minutes and note the pressure again.

If the pressure change is less than 5 hPa, the sample gas path is adequately tight.

This value is based on the tare volume of the measuring module 7 ml and the volume of the

pressure measuring device of 23 ml.

Commissioning

9.6Checking gas paths for leaks

Wall-mounted device

Operating Instructions, 07/2023, A5E31930403-AB 137

Loading...

Loading...