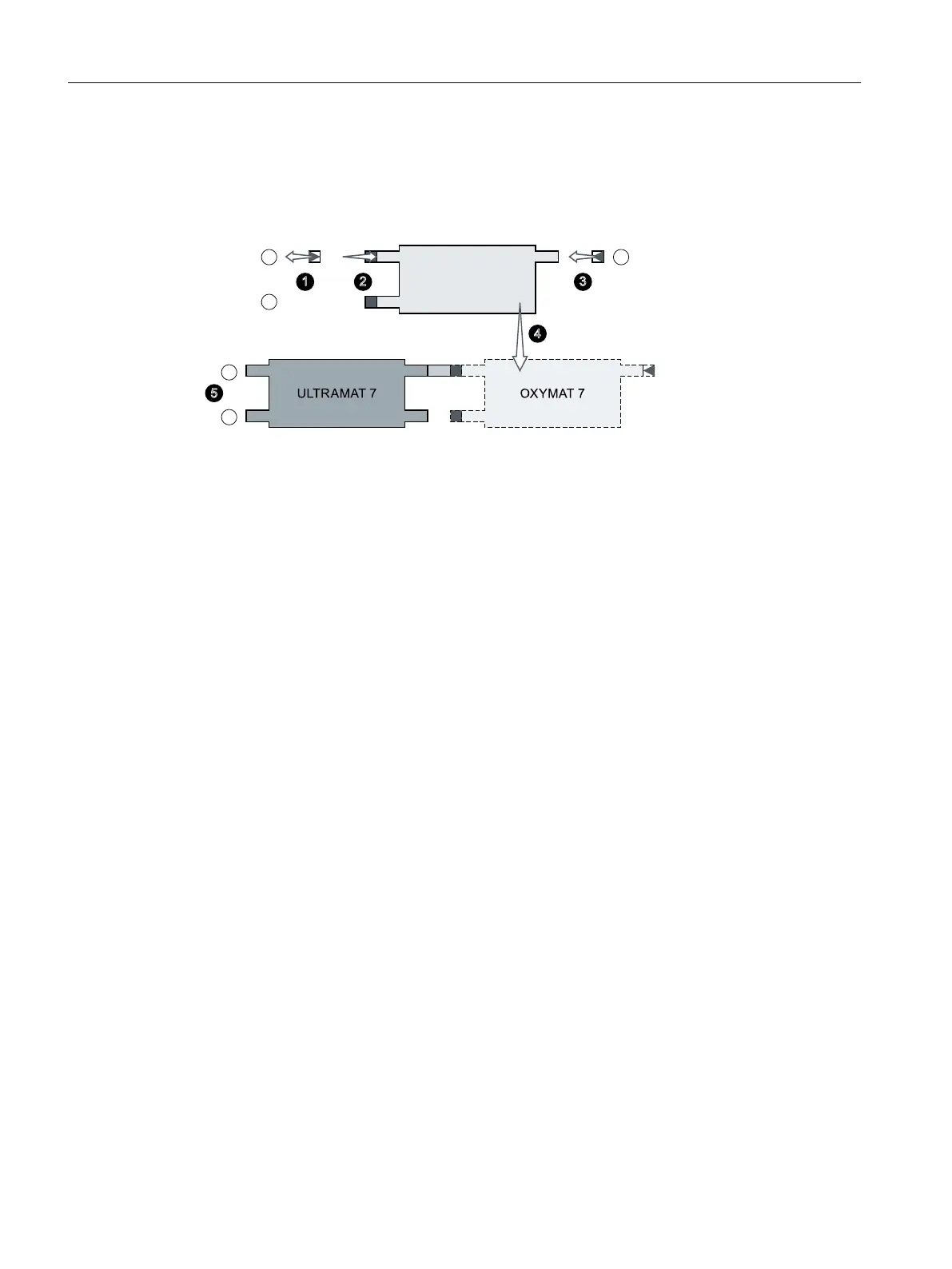

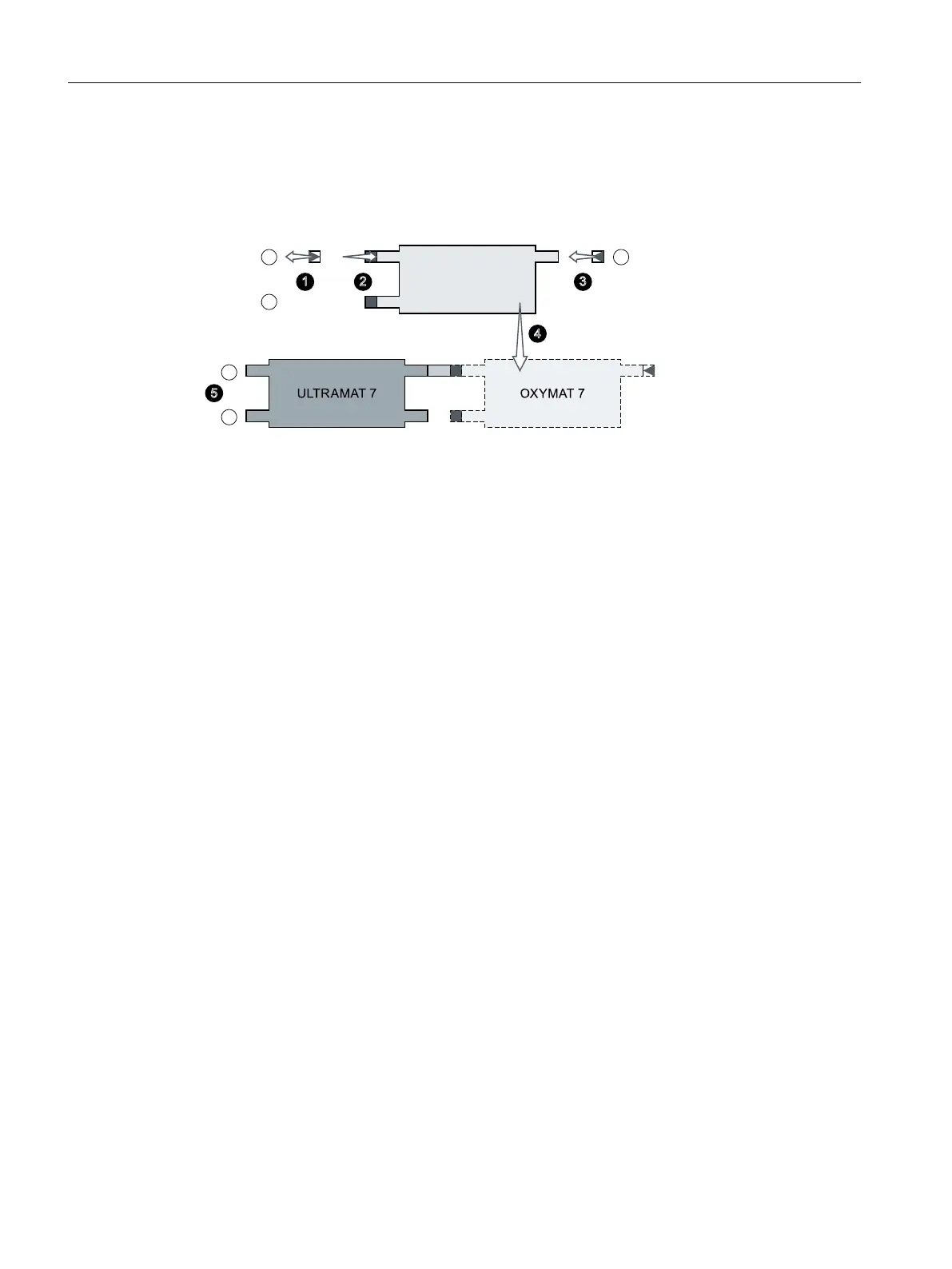

Retrotting example "Suction operation, serial" operating mode for OXYMAT7/ULTRAMAT7

When you are using the ULTRAMAT7 and the OXYMAT7 analyzer module in serial suction

operation, you must convert the sample gas restrictor of the OXYMAT7 analyzer module:

Sample gas inlet → Sample gas outlet.

a Sample gas inlet

b Reference gas inlet

c Sample gas outlet/reference gas outlet

① Remove sample gas restrictor from the sample gas inlet of the additional OXYMAT7 analyzer

module

② Install the clamping screw into the sample gas inlet of the additional OXYMAT 7 analyzer module

③ Install the sample gas restrictor into the sample gas outlet of the additional OXYMAT7 analyzer

module

④ Install additional OXYMAT7 analyzer module

⑤ Target conguration: ULTRAMAT7 and OXYMAT7 in serial suction operation

Figure5-6 Retrotting of the sample gas restrictors: Example "Pressure operation, serial"

5.4.8 Enclosure purging

Enclosure purging

Gases can escape from the gas path on a very small scale and accumulate over a longer period

of time to dangerous levels. Therefore, the enclosure must be purged with dry, dust-free air or

inert gas when dealing with ammable, toxic or highly corrosive sample gases.

Purge the wall-mounted enclosure with a ow rate of approx. 1 l/min. Purging of the

enclosure can only be dispensed with if non-toxic gases or gas mixtures below the lower

explosive limit (LEL) are introduced into the device. Collect the gas displaced by the purging

using a suitable mechanism. Dispose of the gas in an environmentally friendly way, for

example, via an exhaust pipe.

Combined operation

5.4Application planning

Wall-mounted device

52 Operating Instructions, 07/2023, A5E31930403-AB

Loading...

Loading...