VALVES AND VALVE SPRINGS (YP125R)

5-23

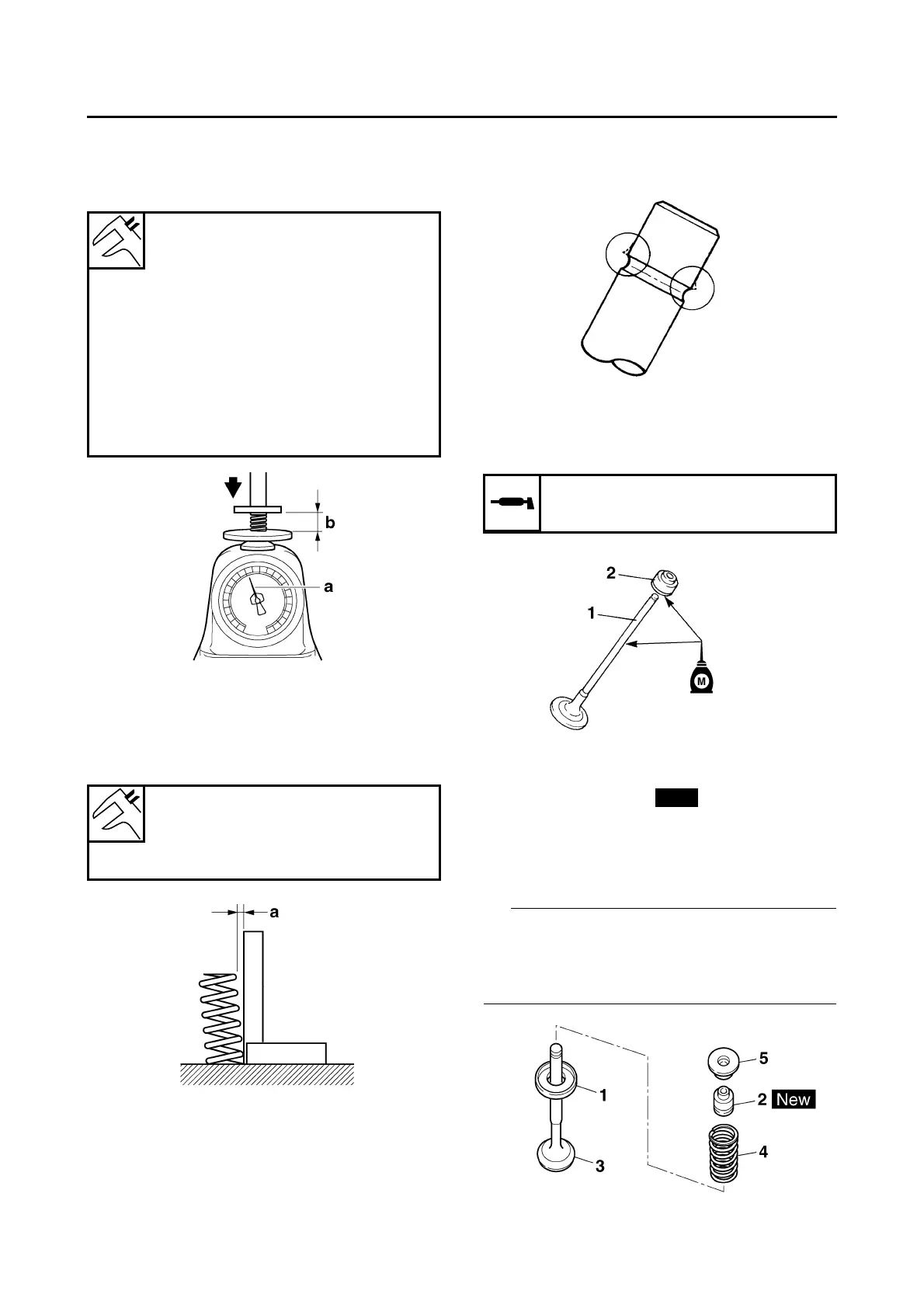

2. Measure:

• Compressed valve spring force “a”

Out of specification → Replace the valve

spring.

3. Measure:

• Valve spring tilt “a”

Out of specification → Replace the valve

spring.

EAS37P1018

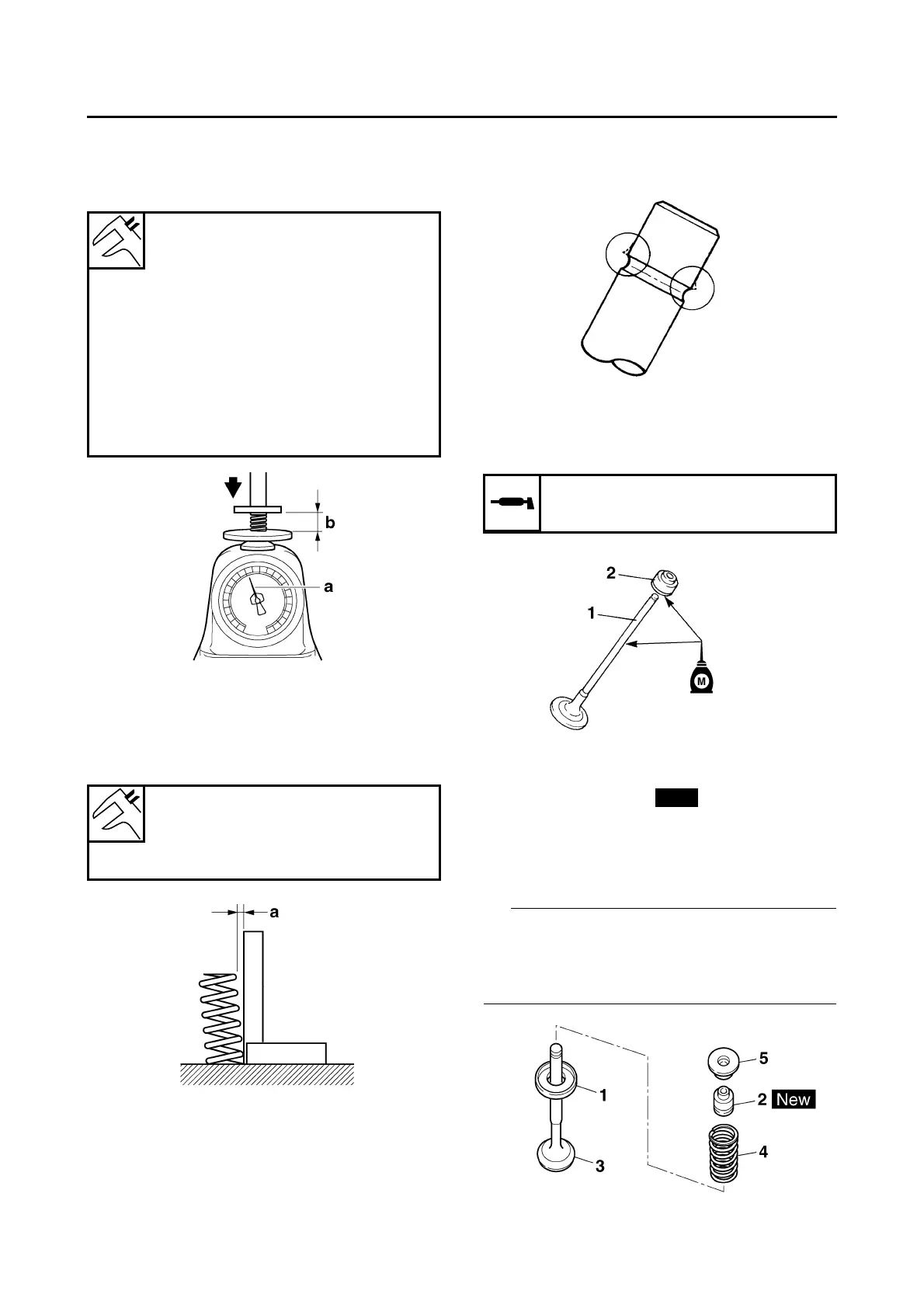

INSTALLING THE VALVES

The following procedure applies to all of the

valves and related components.

1. Deburr:

• Valve stem end

(with an oil stone)

2. Lubricate:

• Valve stem “1”

• Valve stem seal “2”

(with the recommended lubricant)

3. Install:

• Lower spring seat “1”

• Valve stem seal “2”

• Valve “3”

• Valve spring “4”

• Upper spring seat “5”

(into the cylinder head)

IP

• Make sure each valve is installed in its original

place.

• Install the valve springs with the larger pitch “a”

facing up.

Installed compression spring

force (intake)

140–162 N (14.28–16.52 kgf,

31.47–36.42 lbf)

Installed compression spring

force (exhaust)

140–162 N (14.28–16.52 kgf,

31.47–36.42 lbf)

Installed length (intake)

35.30 mm (1.39 in)

Installed length (exhaust)

35.30 mm (1.39 in)

b. Installed length

Spring tilt (intake)

2.5°/1.8 mm

Spring tilt (exhaust)

2.5°/1.8 mm

Recommended lubricant

Molybdenum disulfide oil

New

Loading...

Loading...