CRANKSHAFT (YP250R)

5-119

EAS25580

CHECKING THE CRANKCASE

1. Thoroughly wash the crankcase halves in a

mild solvent.

2. Thoroughly clean all the gasket surfaces and

crankcase mating surfaces.

3. Check:

• Crankcase

Cracks/damage → Replace.

• Oil delivery passages

Obstruction → Blow out with compressed air.

EAS37P1067

CHECKING THE BEARING AND OIL SEAL

1. Check:

• Bearing

Clean and lubricate the bearings, and then

rotate the inner race with your finger.

Rough movement → Replace.

EAS37P1068

CHECKING THE OIL STRAINERS

1. Check:

• Oil strainers

Damage → Replace.

Contaminants → Clean with solvent.

EAS26210

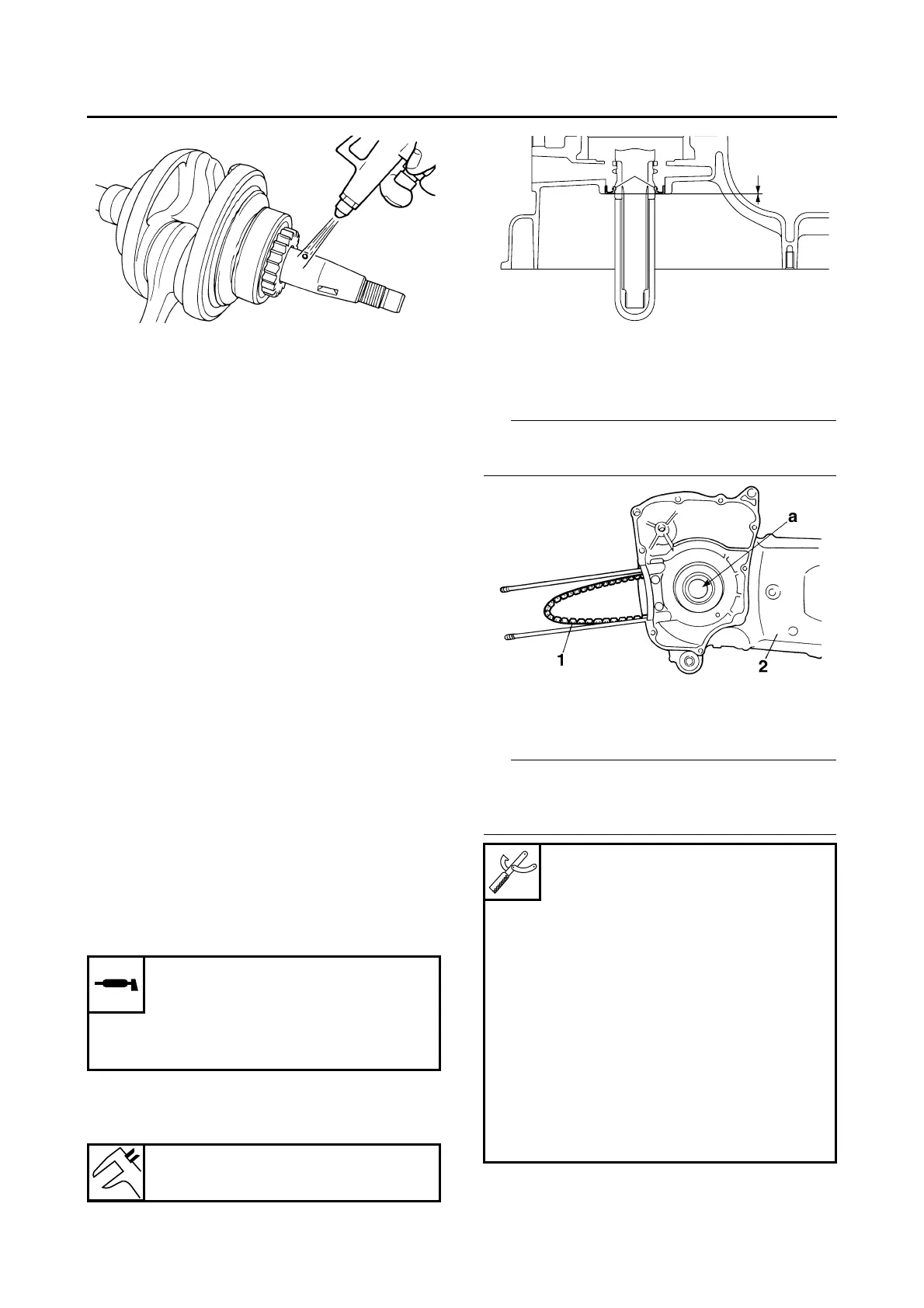

INSTALLING THE CRANKSHAFT

1. Lubricate:

• Oil seals

• Bearings

• Oil pump drive gear

2. Install:

• Oil seal “1”

(to the left crankcase)

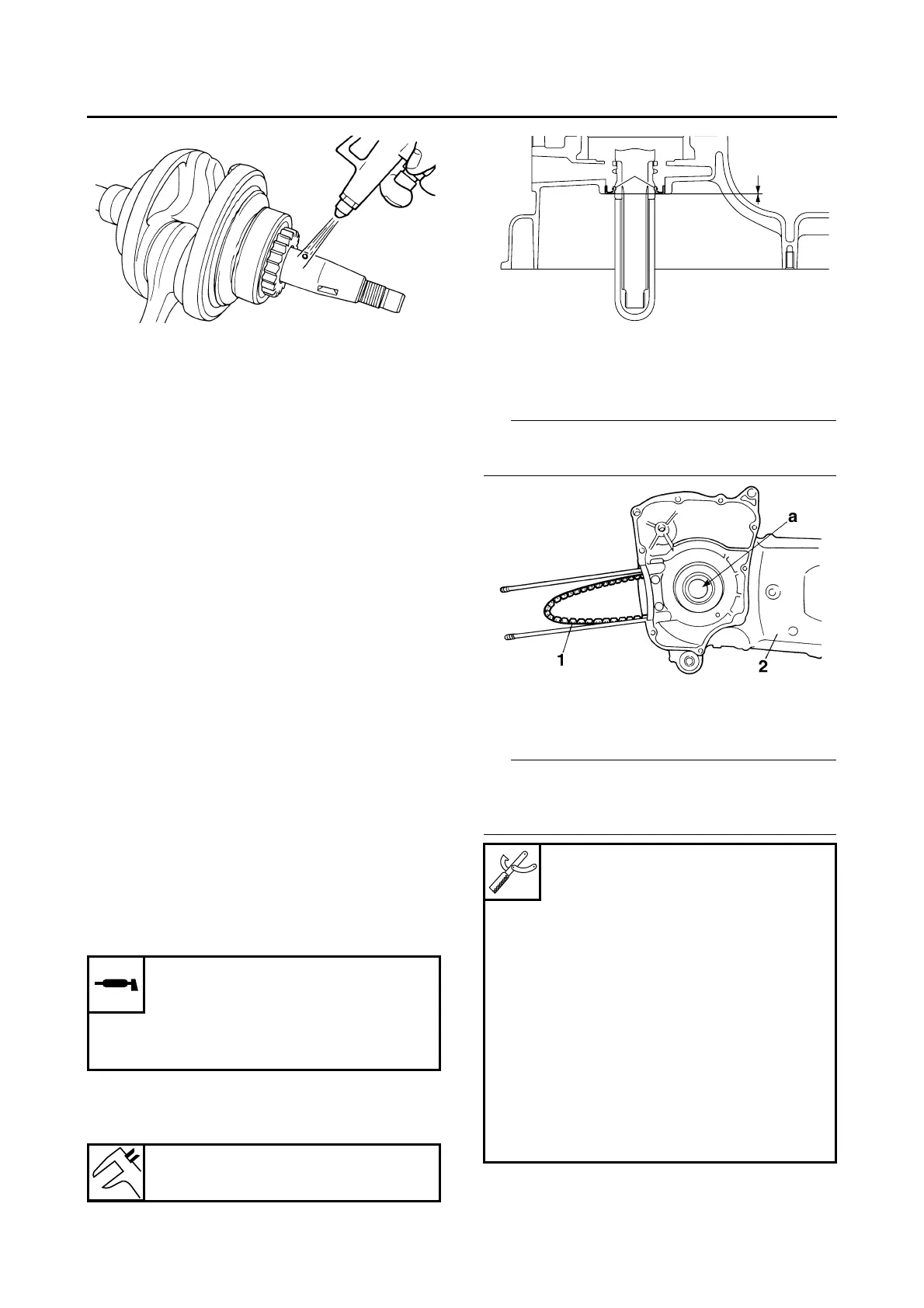

3. Install:

• Timing chain “1”

IP

Install the timing chain so it is not visible through

the opening “a” in the left crankcase “2”.

4. Install:

• Crankshaft assembly “1”

(to the left crankcase)

IP

Install the crankshaft assembly with the crank-

shaft installer pot “2”, crankshaft installer bolt “3”,

adapter “4”, and spacer “5”.

Recommended lubricant

Oil seal

Lithium-soap-based grease

Bearing, oil pump drive gear

Engine oil

Oil seal installed depth

0–0.5 mm (0–0.020 in)

a. Oil seal installed depth

Crankshaft installer pot

90890-01274

Installing pot

YU-90058

Crankshaft installer bolt

90890-01275

Bolt

YU-90060

Adapter (M14)

90890-01478

Adapter #6

YM-90066

Spacer (crankshaft installer)

90890-04081

Pot spacer

YM-91044

a

1

Loading...

Loading...