2 THERMAL OVERLOAD PROTECTION

Transformer overheating can be caused due to failures of the cooling system, external faults that are not cleared

pr

omptly, or overload and abnormal system conditions. These abnormal conditions include low frequency, high

voltage, non-sinusoidal load current, or phase-voltage imbalance.

Overheating shortens the life of the transformer insulation in proportion to the duration and magnitude of the high

temperature. If excessive, this may even result in an immediate insulation failure. Overheating can also generate

gases that could result in electrical failure, or cause the transformer coolant to be heated above its flashpoint

temperature, introducing the risk of fire.

Studies suggest that the life of insulation is approximately halved for each 10°C rise in temperature above the

rated value. However, the life of insulation is not wholly dependent on the rise in temperature but on the time the

insulation is subjected to this elevated temperature. Due to the relatively large heat storage capacity of a

transformer, infrequent overloads of short duration may not damage it. However, sustained overloads of a few

percent may result in premature aging and consequent insulation failure.

Transformer thermal overload protection is designed to protect equipment from sustained overload. Thermal

overload protection allows modest but transient overload conditions to occur, while tripping for sustained

overloads, which would not be detected by standard overcurrent protection.

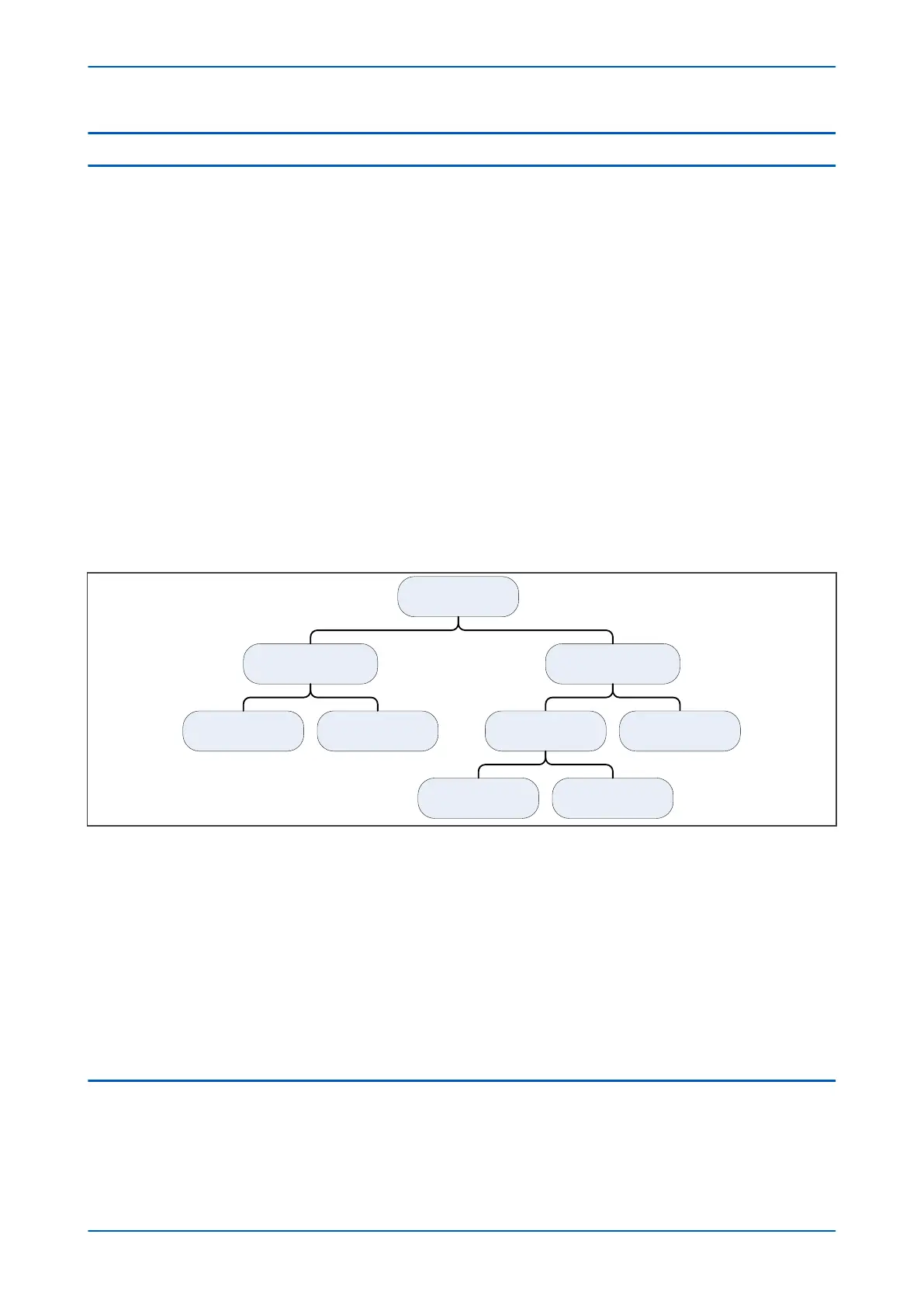

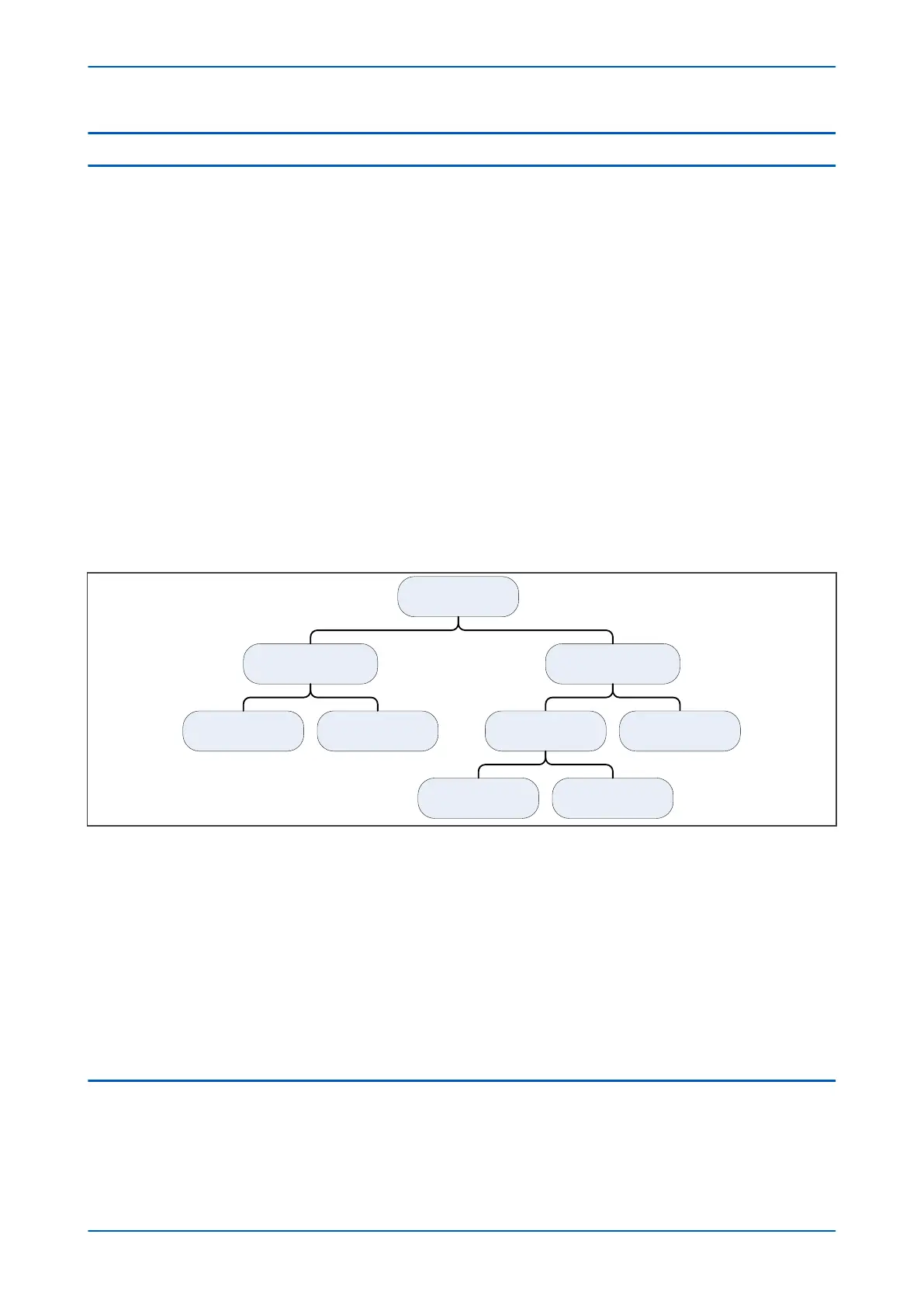

Transformer Losses

The losses in a transformer are shown in the following diagram:

V03200

Transformer Losses

Load Losses No Load Losses

Copper Losses

Eddy-current Losses Hysteresis Losses

Stray Losses Apparent Losses

Core Losses

(Iron Losses)

Figure 62: Transformer losses

The flow of the magnetising curr

ent through the resistance of the winding creates a real but generally relatively

small I

2

R loss and voltage drop. The loss that is due to this magnetizing current in the primary winding is called the

apparent loss.

Time-varying fluxes in iron-based materials, cause losses called core losses, or iron losses. These iron losses are

divided into two categories; hysteresis losses and eddy-current losses.

The sum of copper losses and the stray losses is called the load loss. Copper losses are due to the flow of load

currents through the primary and secondary windings. They are equal to I

2

R, and they heat up the wires and

cause voltage drops. Stray losses are due to the stray capacitance and leakage inductance. Stray capacitance

exists between turns, between one winding and another, and between windings and the core.

2.1 THERMAL OVERLOAD IMPLEMENTATION

The thermal overload protection in this device is based on the IEEE Standard C57.91-1995. It provides thermal

overload protection for either an individual winding or the transformer as a whole. The thermal overload

protection settings are in the THERMAL OVERLOAD column.

Chapter 7 - Transformer Condition Monitoring P64x

144 P64x-TM-EN-1.3

Loading...

Loading...